Rock core oil cleaning instrument

A technology of oil washing instrument and core, applied in the preparation of test samples, etc., can solve the problems of low efficiency and poor cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

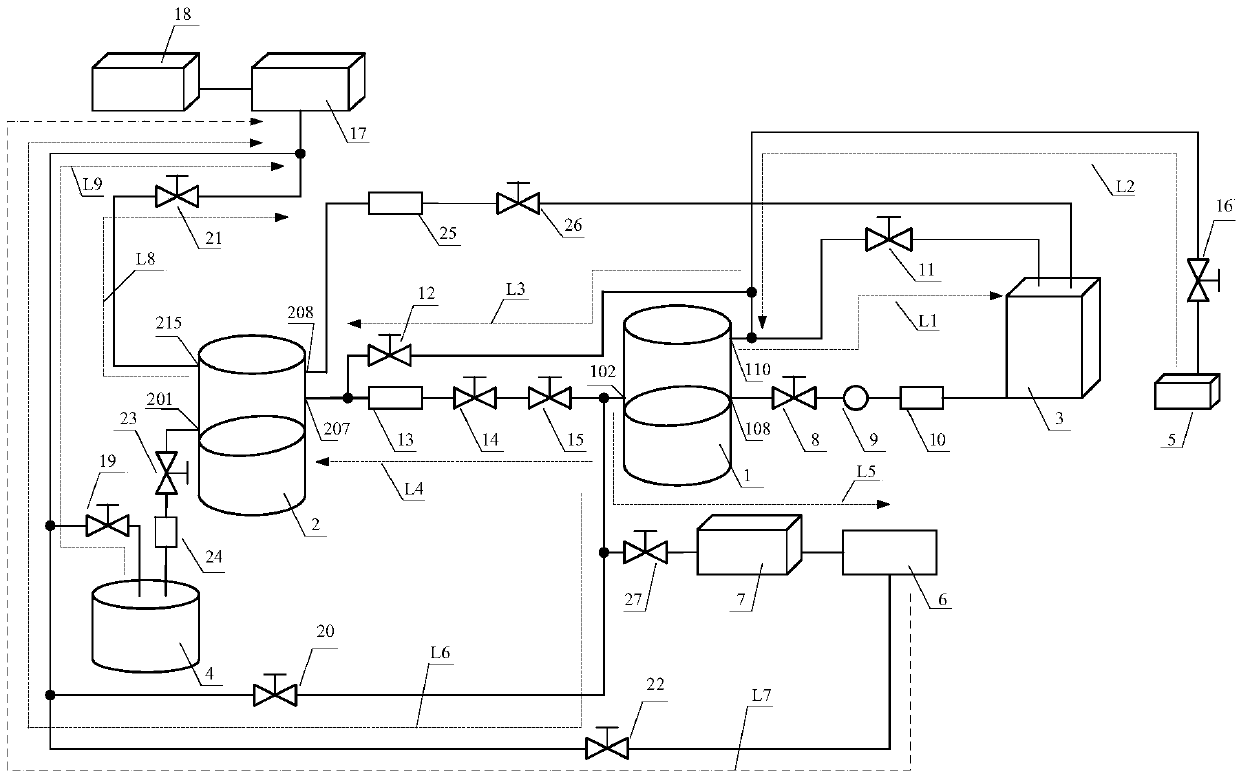

[0033] The structure of the core oil washing instrument of the present invention is as figure 2 shown. Overall, the core oil washing instrument includes a sample cleaning system and a waste liquid treatment system.

[0034] The sample cleaning system includes a core kettle 1, a liquid storage tank 3, a gas injection pump 5 and a negative pressure system.

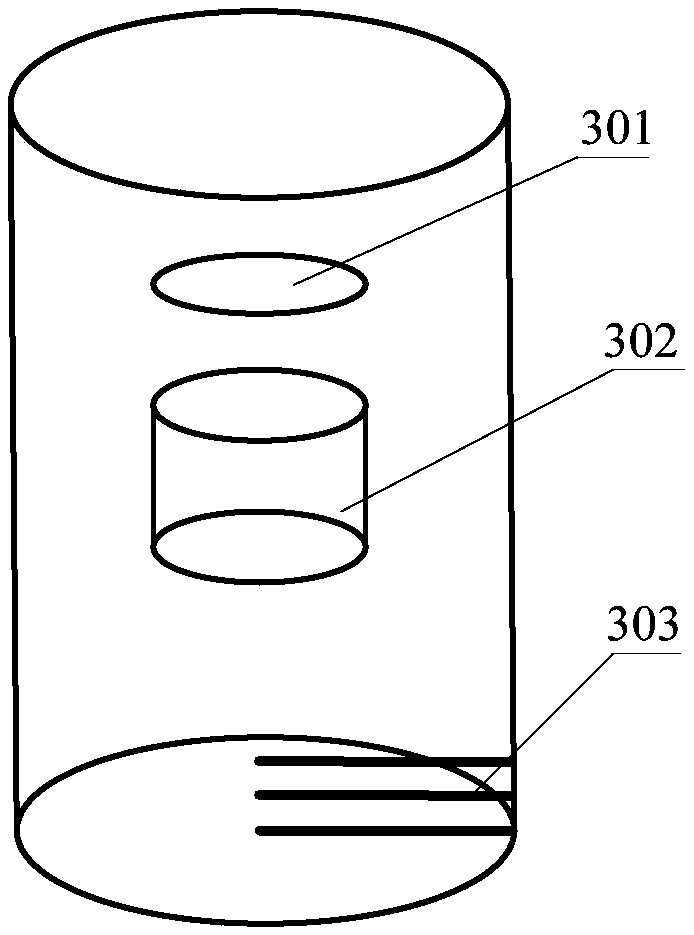

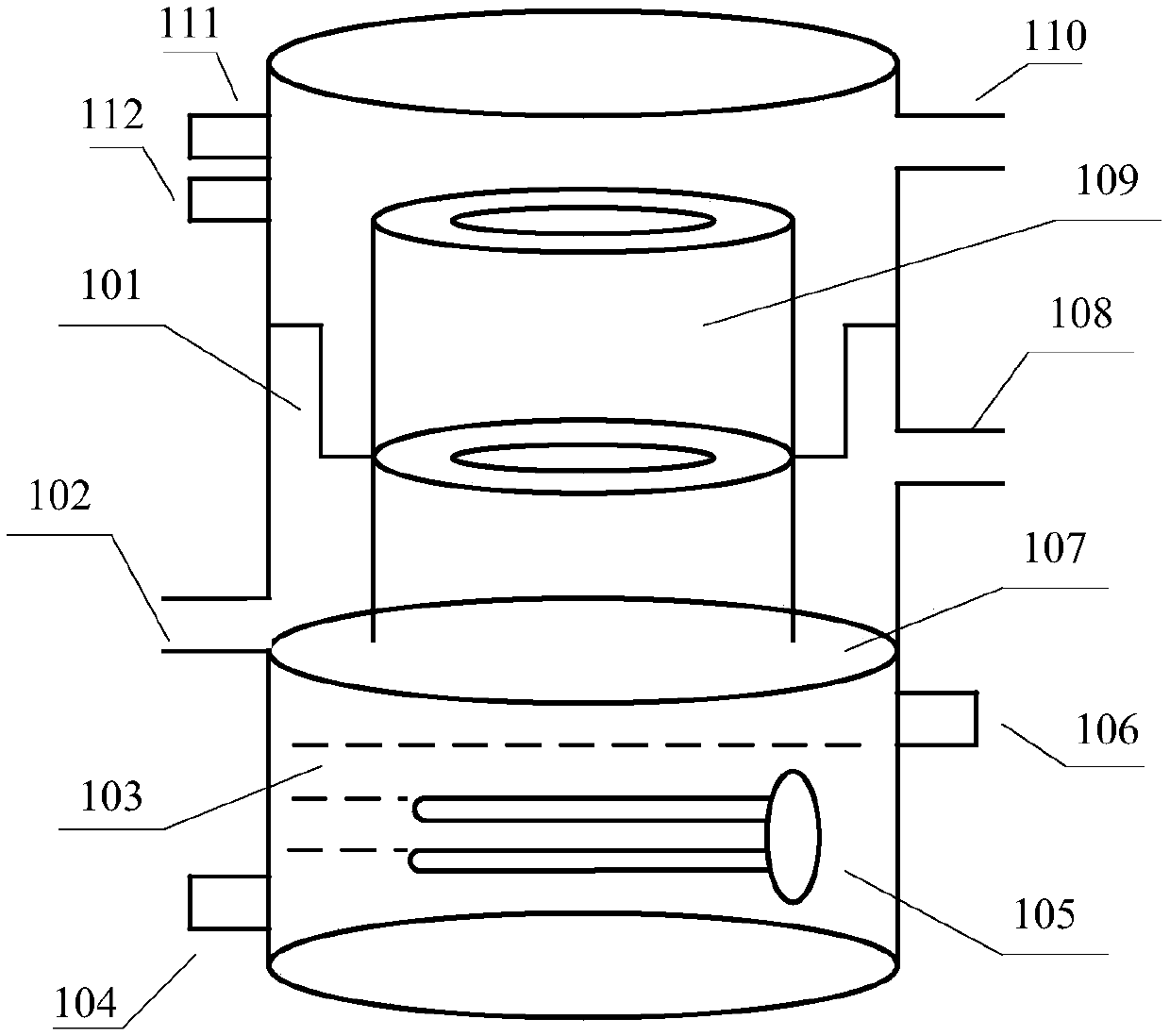

[0035] The core kettle is a closed container for cleaning rock samples, and its specific structure is as follows: image 3 As shown, the internal space is divided into upper and lower chambers by a heat-conducting inclined partition 107 . The thermally conductive inclined partition is set to be high on one side and low on the other side. image 3 The middle performance is high on the right a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com