Full automatic controller of heat exchange unit

A heat exchange unit, fully automatic technology, applied in the direction of household heating, household heating, heating methods, etc., can solve the problems of unobvious application advantages, increased investment, unfavorable integrated automatic control, etc., and achieve good application prospects and social Economic benefits, stable and reliable work, complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

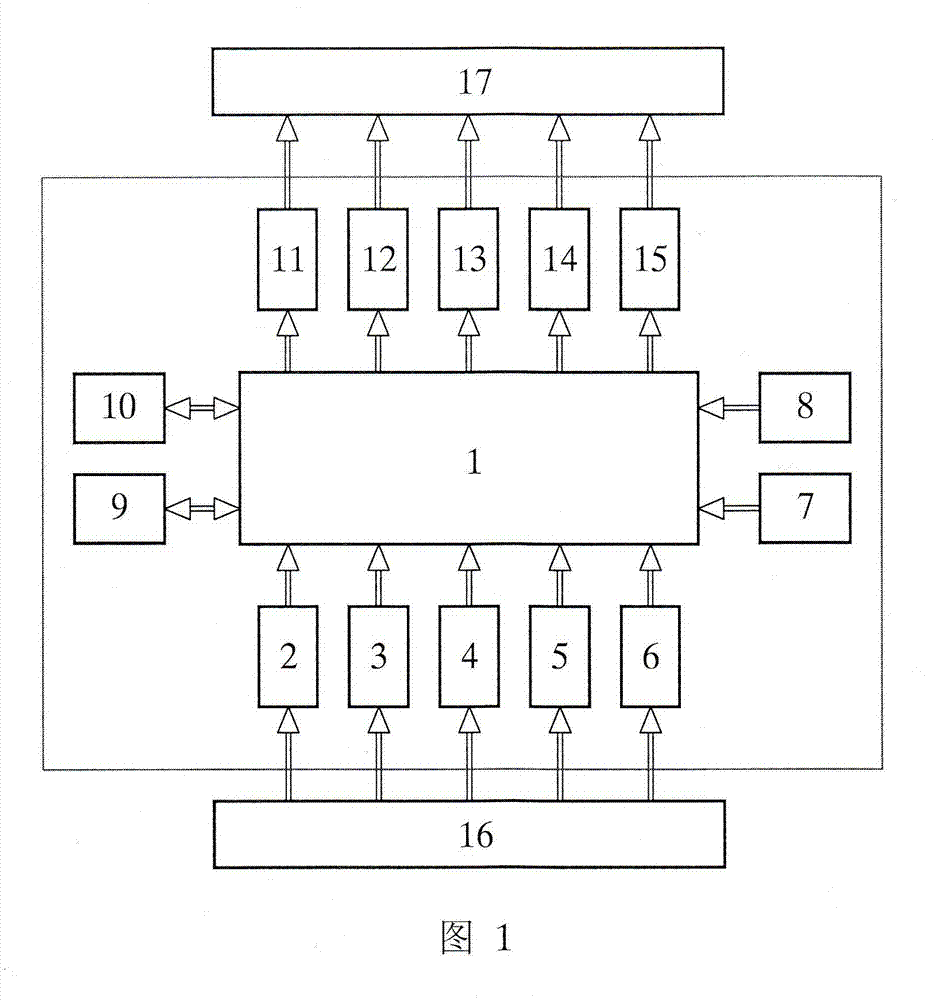

[0011] attached below figure 1 The full-automatic controller of the heat exchange unit of the present invention is described in detail below.

[0012] as attached figure 1 As shown, the automatic controller of the heat exchange unit of the present invention is mainly composed of a central processing unit 1, a digital quantity acquisition unit 2, an analog quantity acquisition unit 3, a temperature acquisition unit 4, a state acquisition unit 5, a fault acquisition unit 6, and a relay output Unit 11, analog output unit 12, temperature adjustment output unit 13, pressure adjustment output unit 14 and fault output unit 15, the central processing unit 1 through the digital acquisition unit 2, analog acquisition unit 3, temperature acquisition unit 4, status The acquisition unit 5 and the fault acquisition unit 6 are connected to the heat exchange unit 16 by wiring, and the central processing unit 1 communicates with the relay output unit 11, the analog output unit 12, the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com