Card engine

A technology of combing machine and rotating cover, which is applied in textiles and papermaking, fiber processing safety devices, fiber processing, etc. It can solve the problems of high connection cost, poor accuracy and high cost of strain gauges, and achieve small delay and extended life , the effect of rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

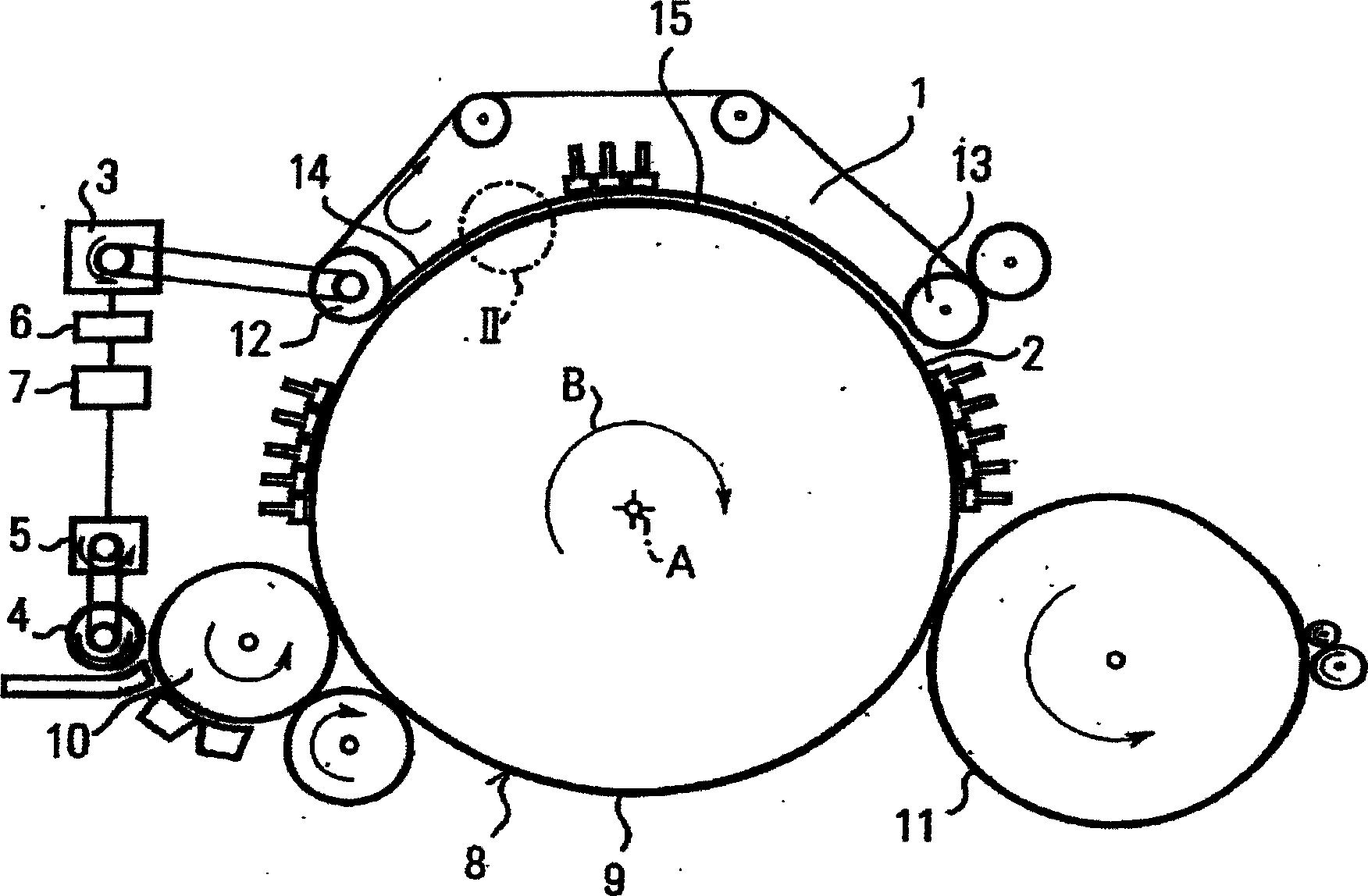

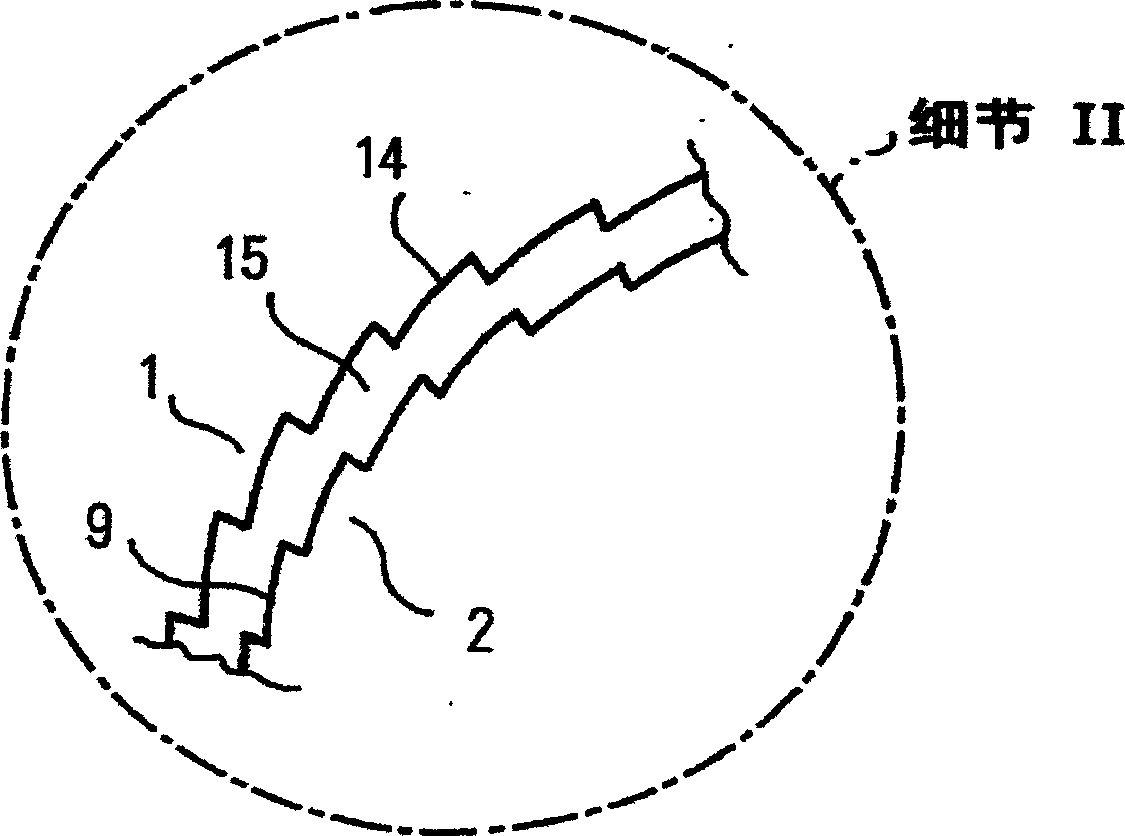

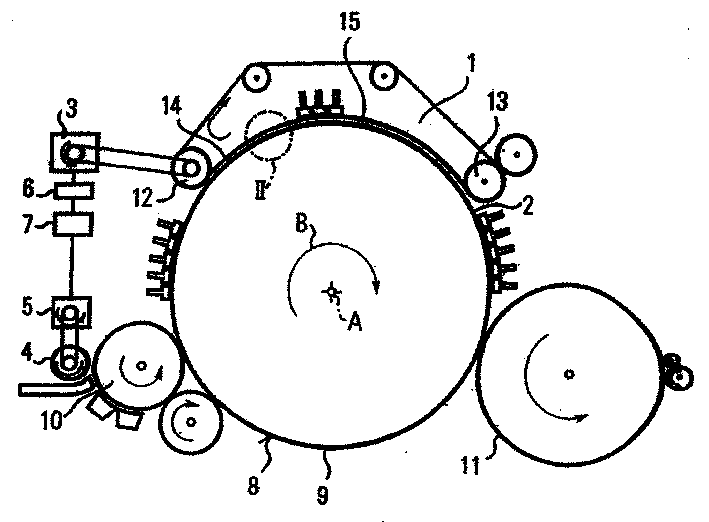

[0021] Embodiments of the present invention will be described with reference to the accompanying drawings.

[0022] As shown in FIG. 1 , shown in plan: the carding machine perpendicular to the axis of rotation of the carding roller or drum 2 . The cladding surface 8 of the drum 2 is fitted with a set 9 for handling the fibrous material. The adjuster 9 consists of a tensioned toothed wire, wherein the tips of the individual teeth point in the direction of rotation or carding B. The design of such a regulator 9 is well known in the prior art and will not be described further here. It can be seen that the direction indicated by the arrow B is the direction in which the drum 2 rotates clockwise. On the left, the figure has a schematic representation of an open-width roll 10 , which feeds the drum 2 with fibers. The supply unit 4 is connected to the open roll 10, said unit supplying the open roll 10 with fibers. It is also possible to use known open width roll equipment. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com