Method for calibrating key parameters of asynchronous motor of electric vehicle

A technology for asynchronous motors and electric vehicles, applied in electric vehicles, motor generator control, electronic commutation motor control, etc., can solve the problems of not being able to strictly guarantee the motor, the ratio state, and the inability of the asynchronous motor to maintain the optimal current, etc., to achieve The effect of fine state adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

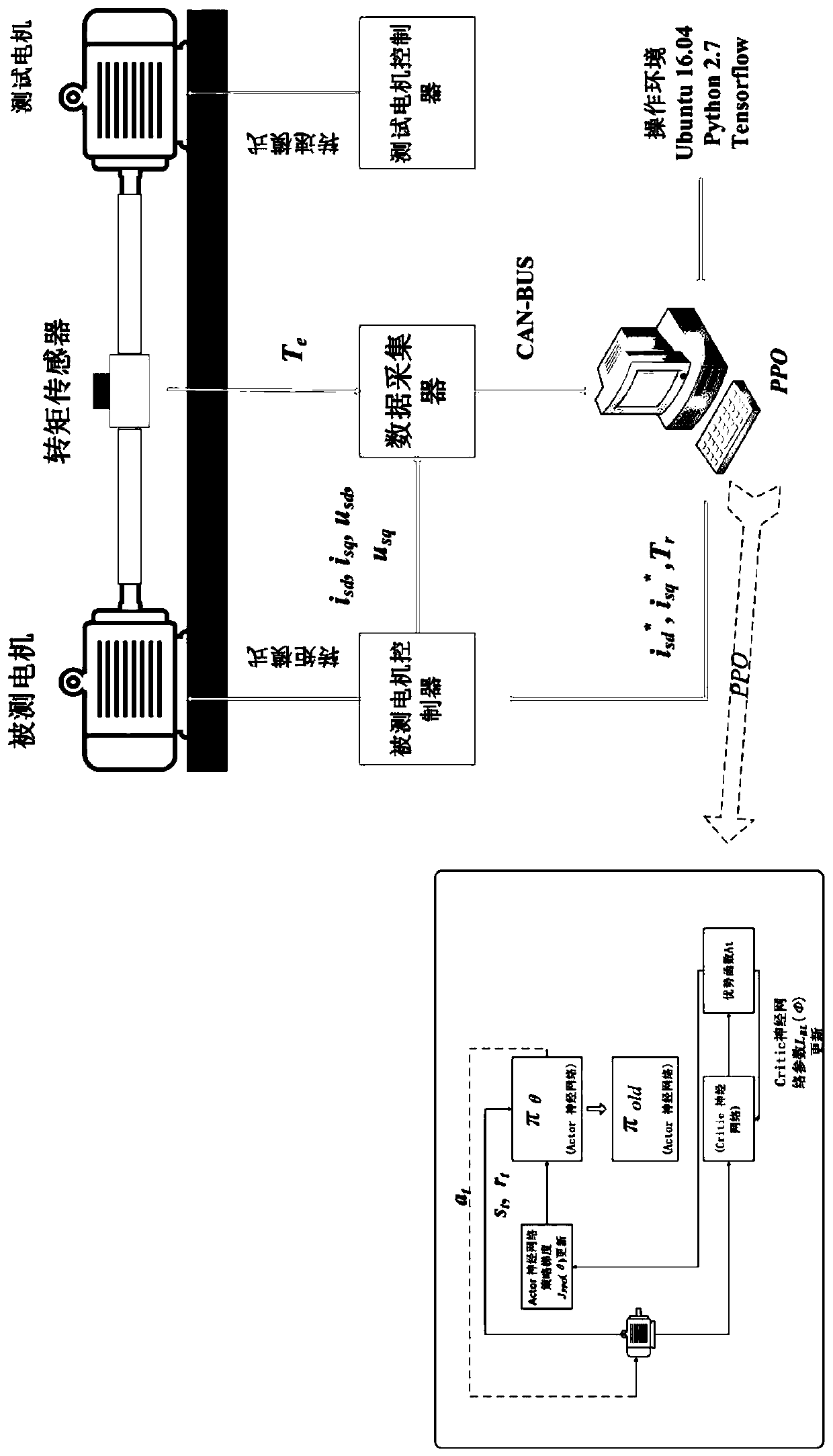

[0039] Such as figure 1 Shown, the instrument equipment that the system of the present invention needs has:

[0040] 1. One motor pair pulls a bench, and the motor of the dynamometer and the motor under test are coaxially installed on the bench. The motor under test is the electric vehicle asynchronous motor that needs to calibrate the key parameter values. The function of the motor of the dynamometer is to The motor under test provides the load and supports the speed of the motor under test. The motor of the dynamometer can be an asynchronous motor or a synchronous motor;

[0041] 2. There are two motor controllers, which are the motor controller under test for controlling the motor under test on the tow stand and the motor controller for the dynamometer controlling the motor of the dynamometer;

[0042] 3. One speed-torque sensor, installed between the motor of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com