Method for replacing floor brush for cleaning for one-key type replacement of roller brush body

A replacement method and technology of rolling brushes, which are applied to cleaning equipment, applications, household appliances, etc., can solve the problems of inability to remove the roller, the rolling brush body falls off, and the rolling brush body is difficult to clean, so as to facilitate cleaning and replacement of the rolling brush body, Reduce maintenance costs and ensure the effect of non-eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

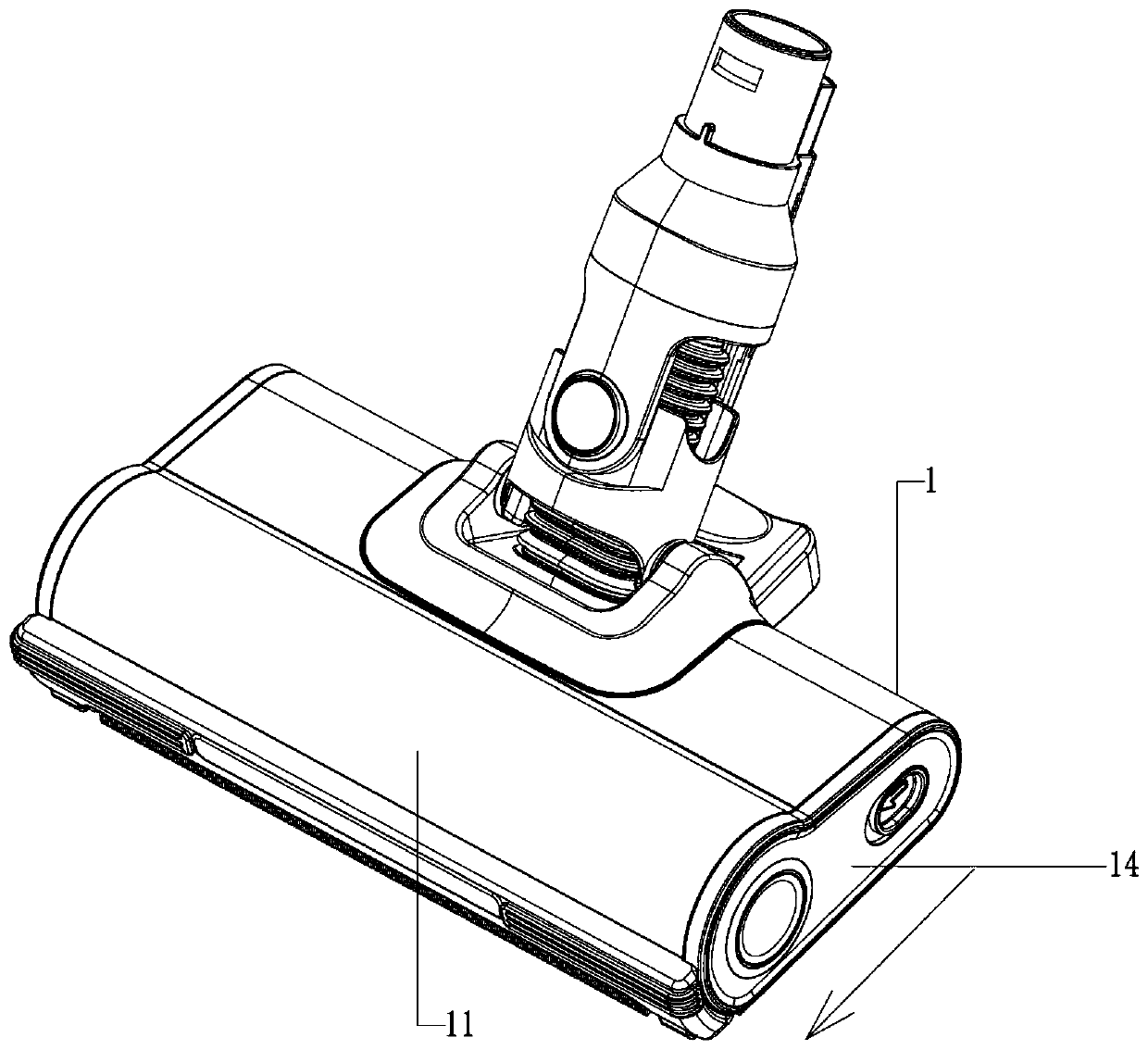

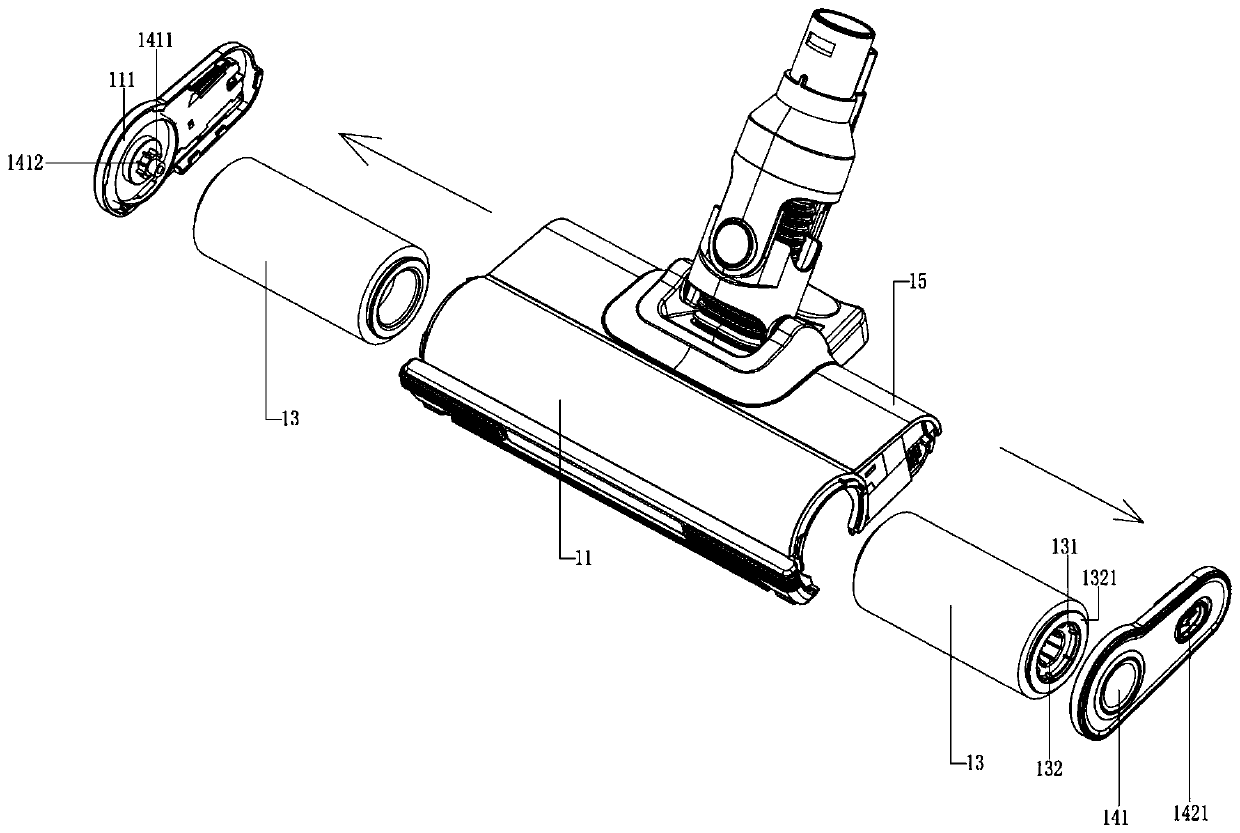

[0035] see Figure 1 to Figure 4 , the figure shows a one-button cleaning floor brush for replacing the rolling brush body provided by the embodiment of the present invention. The rolling brush body 13 and the main body of the transmission assembly 12 are installed in the middle position in the rolling brush chamber 11, and the rolling brush chamber 11 is provided with two symmetrically arranged rolling brush bodies 13, and the inner ends of the two rolling brush bodies 13 are respectively rotatable Connected to the opposite sides of the main body of the transmission assembly 12, the opposite ends of the roller brush chamber 11 are respectively detachably connected with two end covers 14, and the outer end of the roller brush body 13 is rotatably connected to the inner wall of the end cover 14 .

[0036] The main improvement of the floor brush for cleaning with one-button replacement of the rolling brush body provided in this embodiment is that on the basis of setting two rol...

Embodiment 2

[0042] see Figure 1 to Figure 4 , the figure shows a one-button cleaning floor brush for replacing the roller brush body provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: The inner side of the end cover 14 is equipped with a bearing 1411, and the outer end of the roller brush body 13 is provided with a connecting groove 131, and the connecting groove 131 is sleeved on the bearing 1411. A circle of clamping ribs 132 is arranged on the groove wall, and the clamping teeth 1412 are clamped between two adjacent clamping ribs 132 .

[0043] Through the optimized configuration of the above structure, it can be ensured that the end cover realizes stable rotational positioning of the outer end of the roller brush body, which can prevent the roller brush body from falling off and ensure that the roller brush body is not eccentric during operation.

Embodiment 3

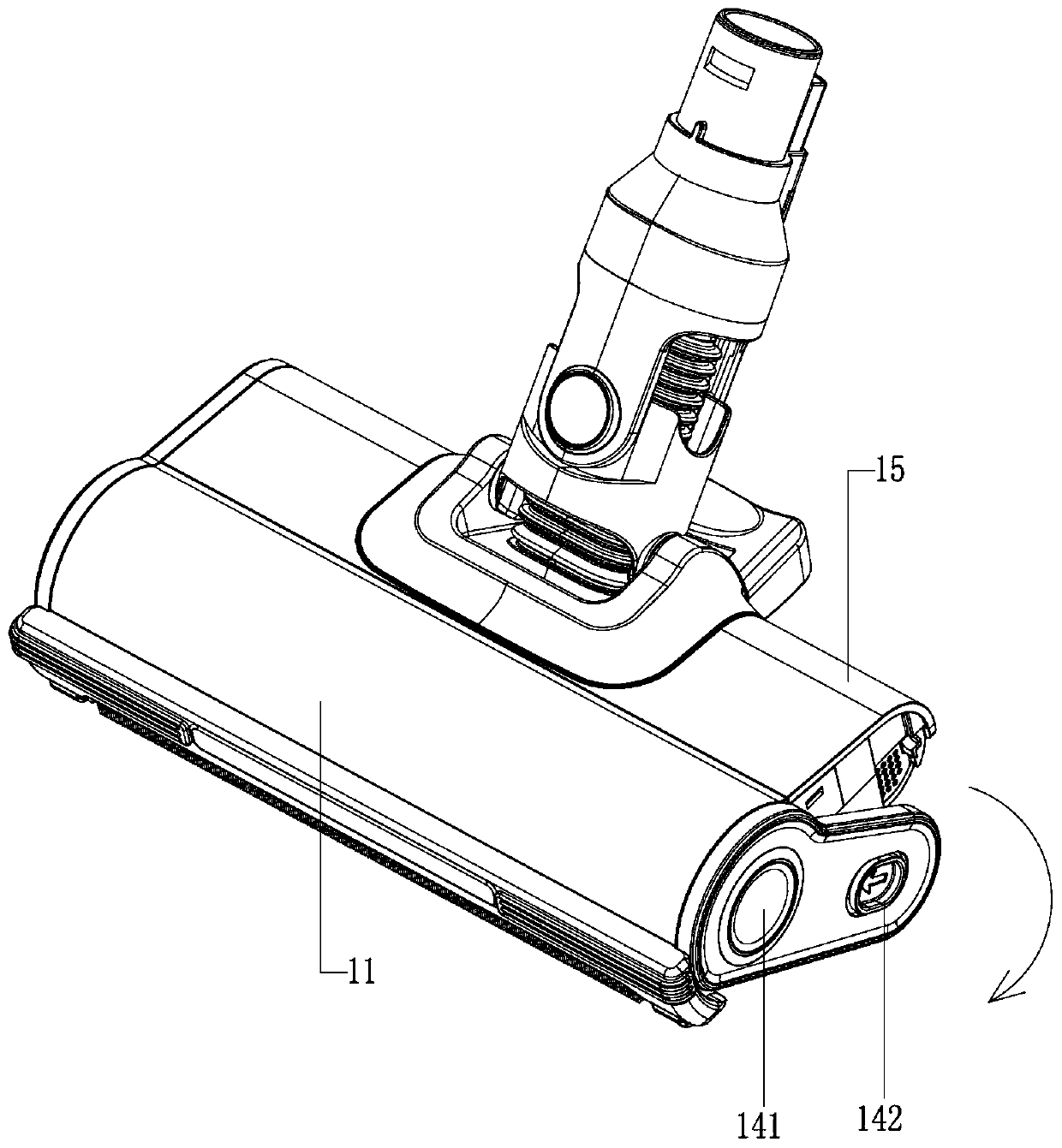

[0045] see Figure 1 to Figure 4 , the figure shows a one-button cleaning floor brush for replacing the roller brush body provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above embodiments: The end cover 14 includes a rotating connection part 141 and a clamping part 142. The rotating connecting part 141 is circular in shape as a whole, and it is rotatably connected to the end of the roller brush chamber 11. The clamping part 142 is clamped to the floor of the floor brush body 1. on the side of the brush housing 15.

[0046] continue to see Figure 1 to Figure 4 , the inner surface of the rotating connection part 141 is provided with an annular convex rib 143, the outer end of the brush body 13 has a convex ring 1321, and the annular rib 143 snaps into the end convex rib 111 and the convex rib of the rolling brush chamber 11. In the gap between circles 1321.

[0047] Continue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com