Mounting method of resin try-on crown and all-ceramic preformed crown thereof

An installation method and a technology for pre-formed crowns, which are applied in the field of dental prosthesis, can solve the problems of difficult adjustment, complicated disinfection, and easy damage of all-ceramic pre-formed crowns, and achieve the effects of low cost, simple operation and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

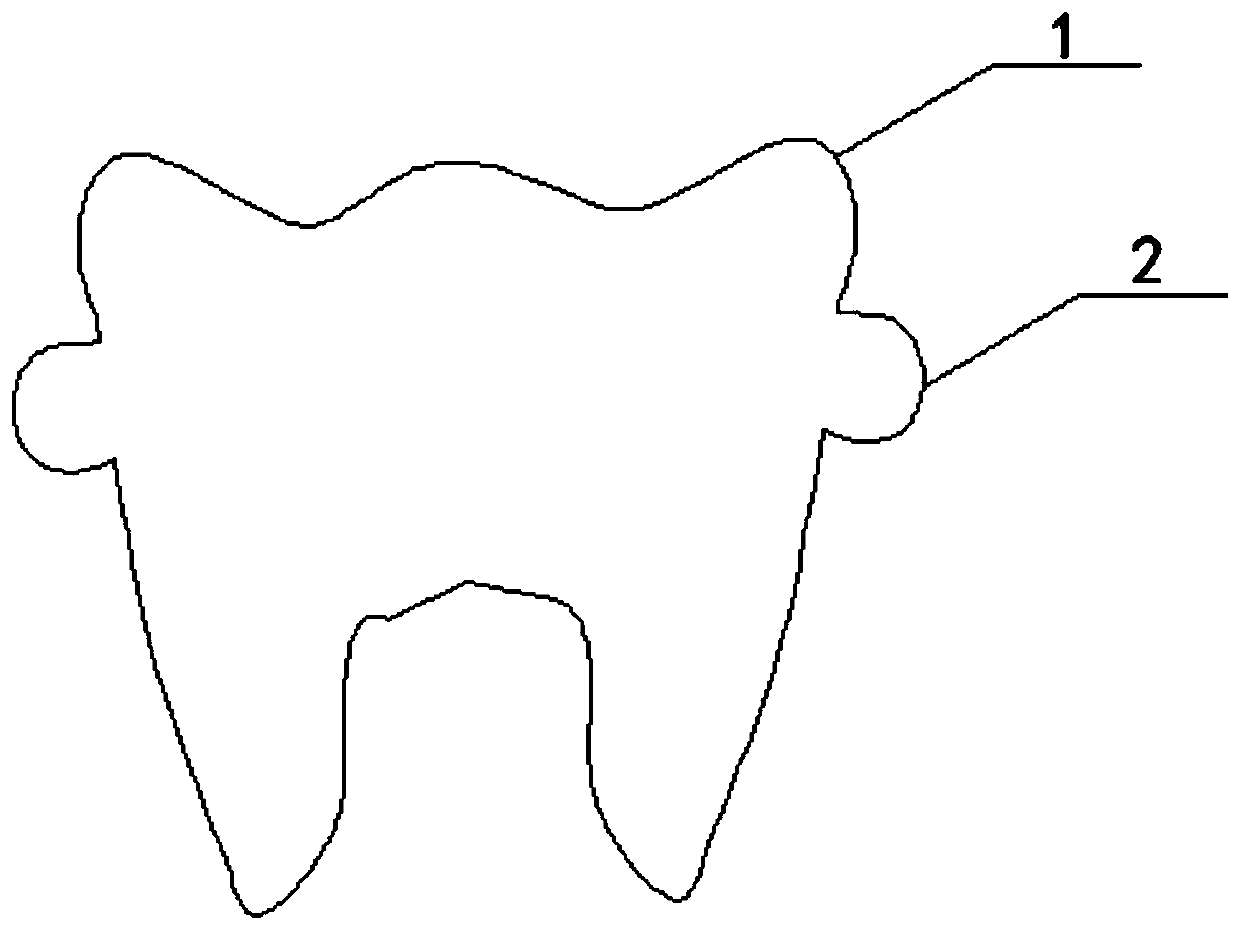

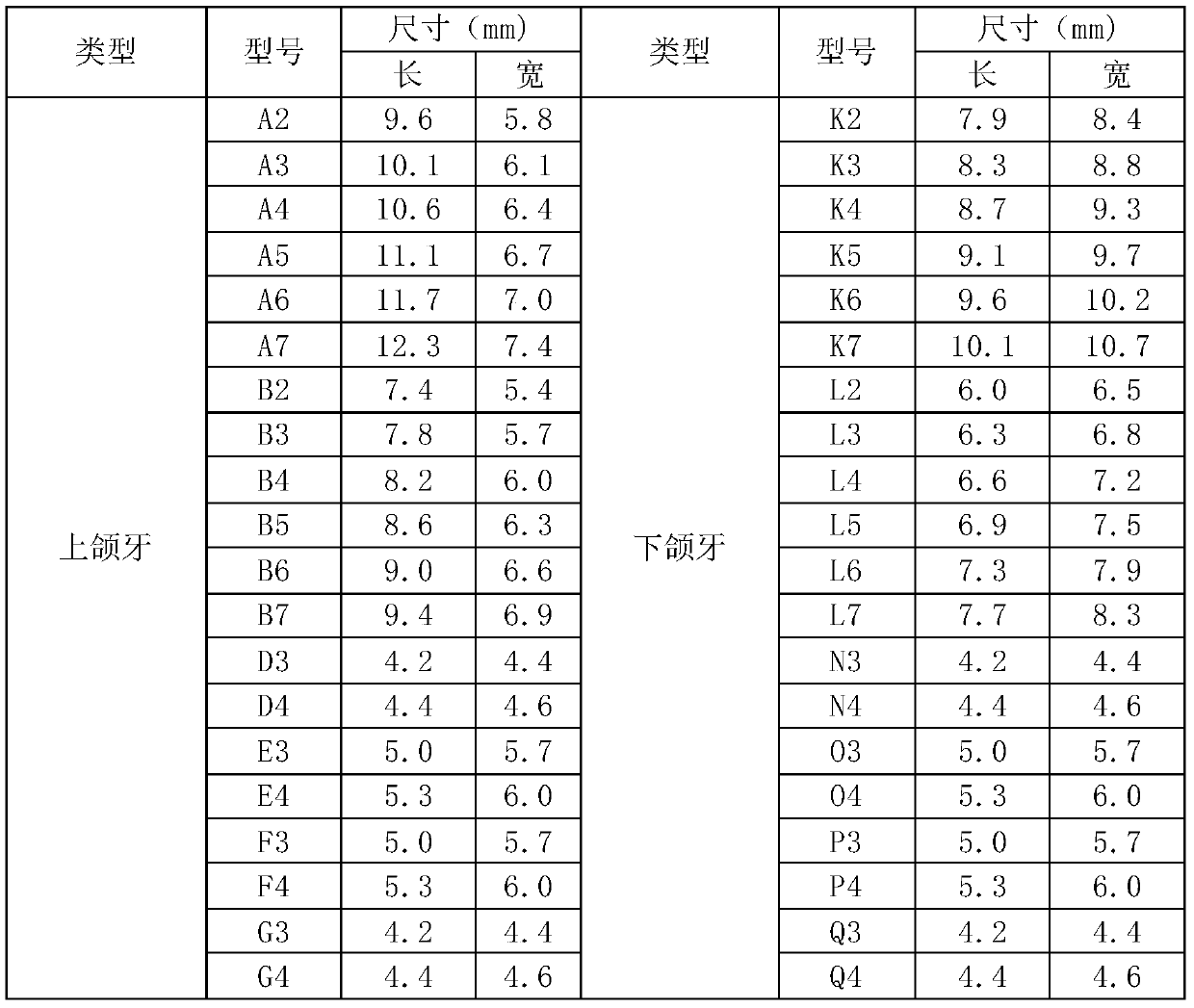

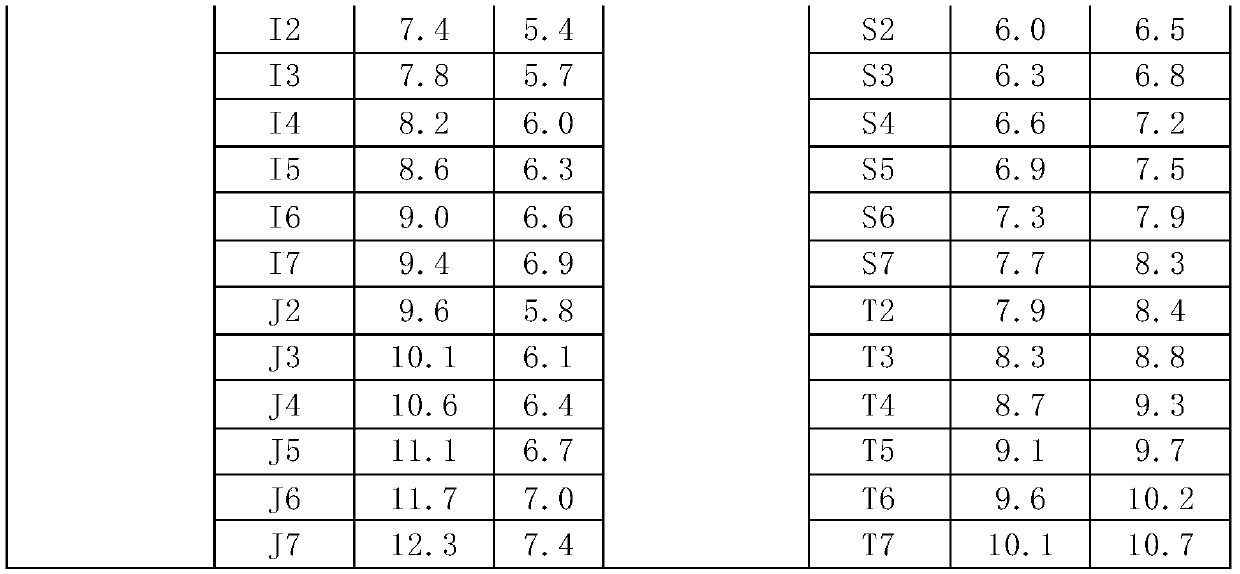

[0026] (1) According to the design data of all-ceramic prefabricated crowns in Table 1, using 3D printing technology, liquid resin (acrylate monomer: methacrylate, photoinitiator: benzoyl peroxide) was used to print and form the resin Try-in crown, the printed resin try-in crown is the same size as the all-ceramic prefabricated crown, the difference is that the resin try-in crown has two protrusions on the surface other than the contact with the adjacent teeth, which is convenient for clamping during try-in.

[0027] (2) Select the appropriate resin try-in crown according to the child's tooth type and size for try-in, and finally obtain the appropriate model of the resin try-in crown;

[0028] (3) According to the model of the appropriate resin try-in tube obtained above, choose the same type of all-ceramic prefabricated crown, after trimming, grinding, and bonding in place, then perform shaping, and correspond to the all-ceramic crown according to Table 2 The order of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com