Concentrate recycling device

A recovery device and concentrate technology, applied to the feed/discharge device of the settling tank, settling tank, chemical instruments and methods, etc., can solve the problems of poor recovery effect, unreasonable feeding structure, etc., and improve the input The effect of improving the material effect, improving the recovery rate, and increasing the sedimentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

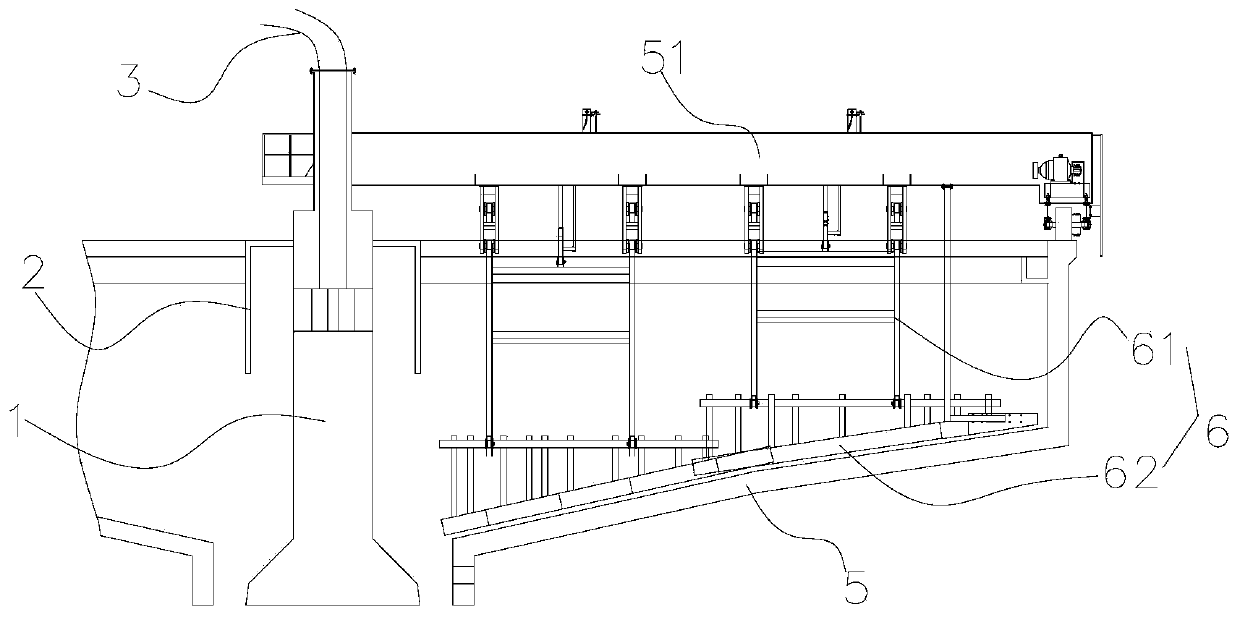

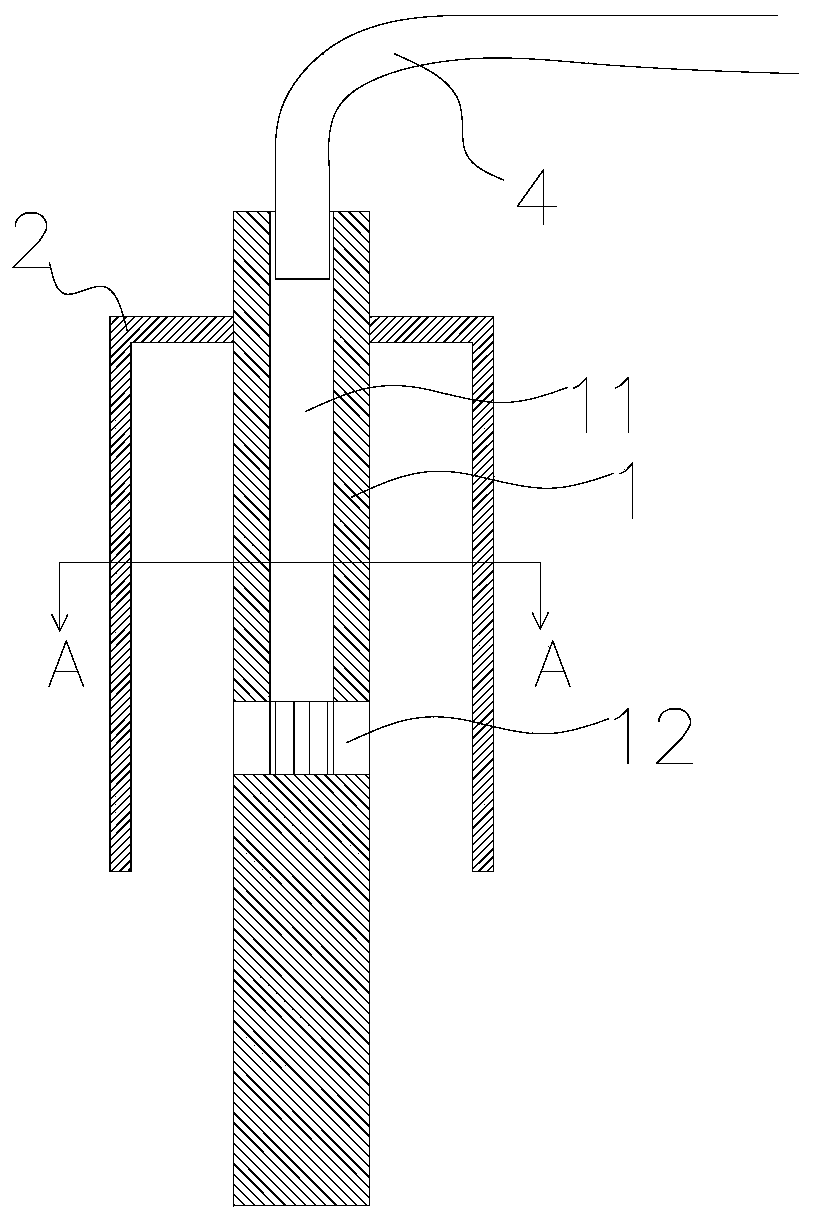

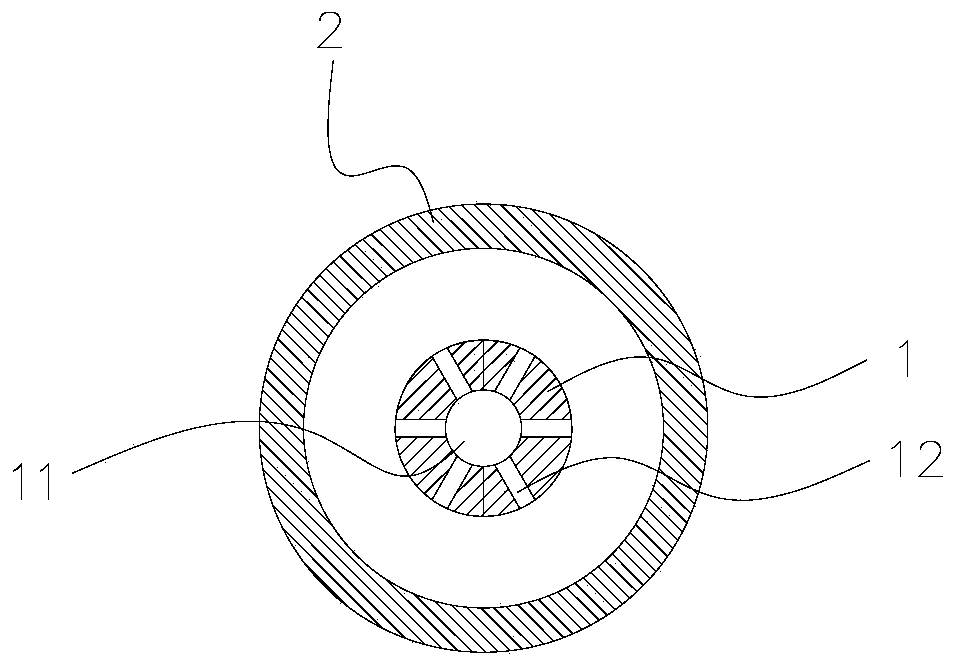

[0047] Such asfigure 1 As shown, a concentrate recovery device includes a concentration tank 5, a feeding mechanism, and the feeding mechanism is fixed in the concentration tank 5. The upper part of the concentration tank 5 is provided with an overflow port, and the bottom is provided with a discharge port. The mechanism includes a feeding solid pipe 1, a steady flow cylinder 2 sleeved outside the feeding solid pipe 1, and a flow guide mechanism 3. Inside the feeding solid pipe 1 is a cavity 11 with an opening at the top, and the opening is the feeding pipe 4 At the access point, the bottom of the cavity is provided with a plurality of discharge holes 12 penetrating with the outside, the steady flow cylinder 2 is set at intervals from the feed solid pipe 1, and the flow guide mechanism 3 is fixed on the feed solid pipe 1, and is in a steady flow Below the cylinder 2, the discharge hole is placed in the turbid layer of the pulp in the thickening tank.

[0048] In this embodimen...

Embodiment 2

[0067] Such as Figure 4 , Figure 5 As shown, the difference between the second embodiment and the first embodiment is that: a flow guiding mechanism 3 is also included.

[0068] In this embodiment, the flow guiding mechanism 3 is a circular frustum structure, and the inside is hollow or solid, not limited to the internal structure.

[0069] The flow direction of the ore pulp is changed by the flow stabilization cylinder 2, and the flow direction is mostly downward, which still produces a certain impact. The flow guide mechanism 3 can change the flow velocity and direction of the ore pulp impacted on the flow stabilization cylinder 2 again, so that the ore pulp The direction of the flow changes to a roughly horizontal direction and enters the turbid layer in a more gradual manner.

Embodiment 3

[0071] Such as Figure 6 As shown, the difference between the third embodiment and the second embodiment is that the setting positions of the feed inlets are different.

[0072] The feed solid pipe 1 is open on the side, and the feed pipe 4 is connected to the opening after passing through the thickener machine wall from the outside of the thickener.

[0073] When feeding, feed pipe 4 can be fixed on the truss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com