Hole flanging structure applied to car safety airbag production

A car safety and hole-turning technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of unimproved inserting knife structure, achieve smooth contact, ensure service life, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

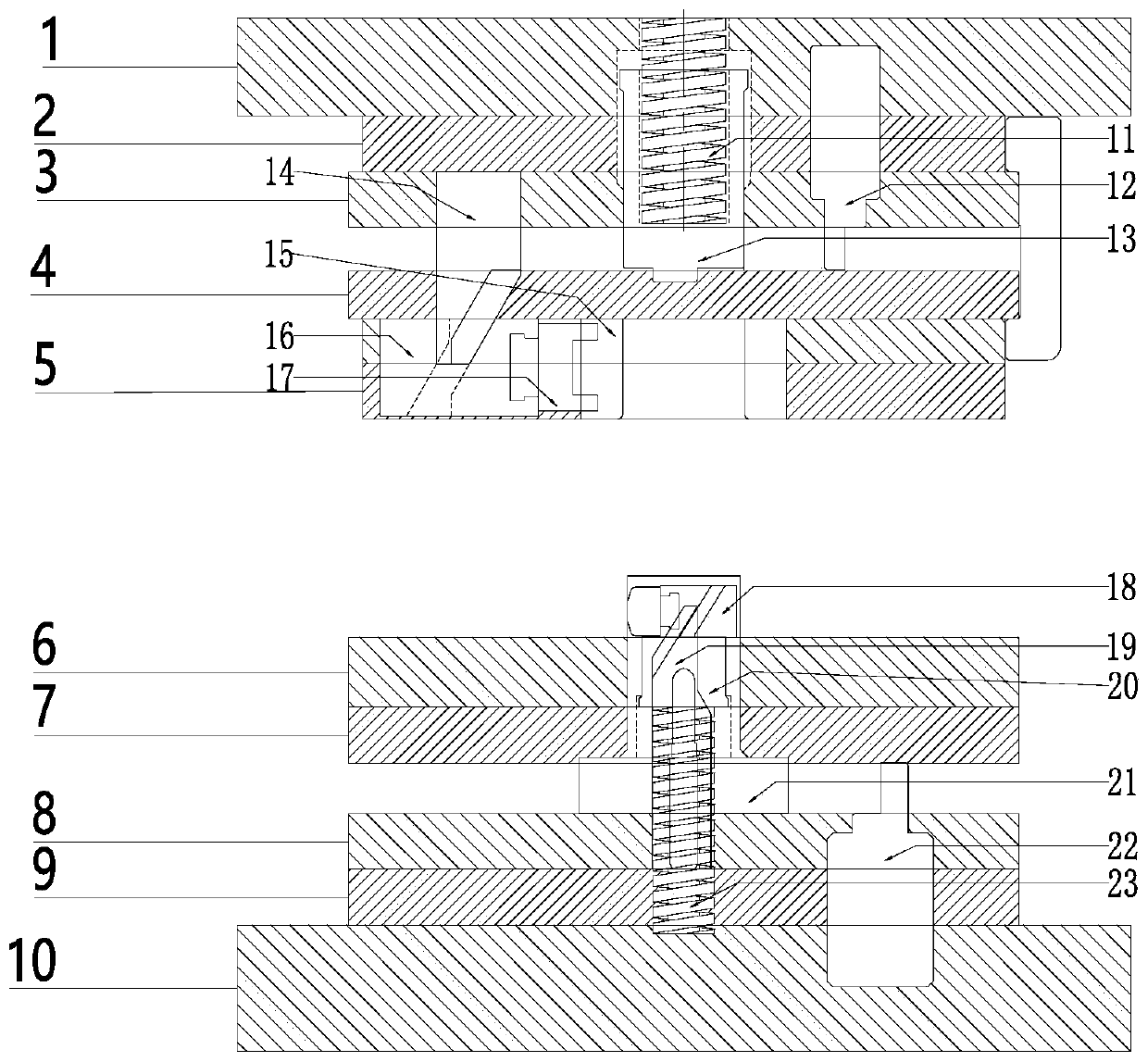

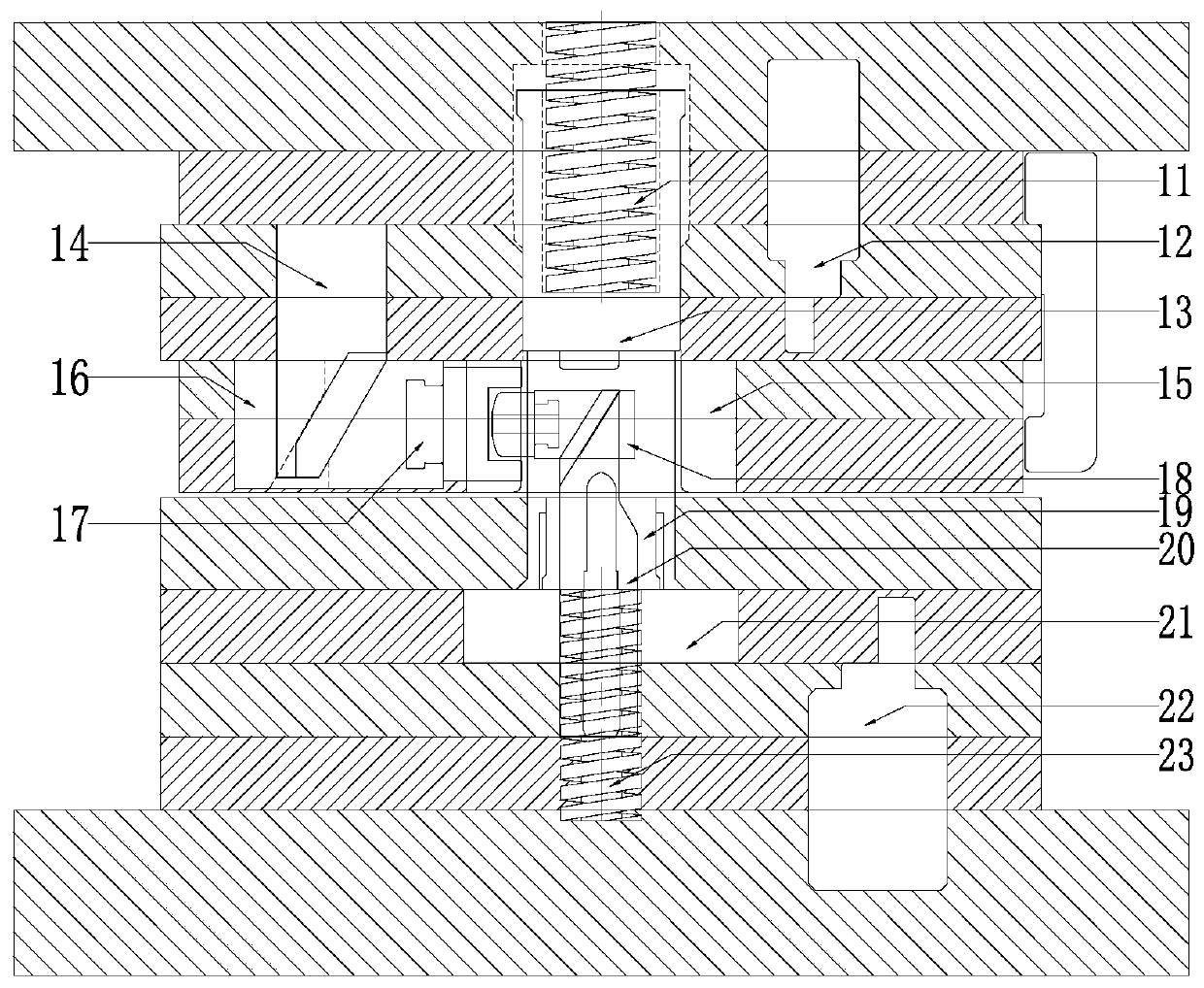

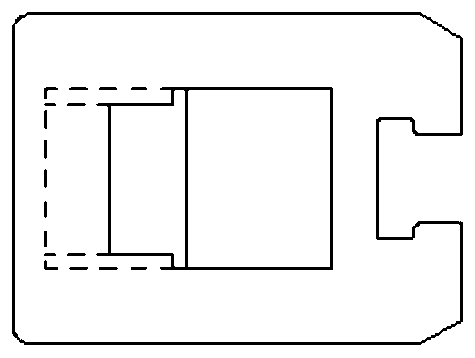

[0035] Such as figure 1-4 shows a hole turning structure applied to the production of automobile airbags, including an upper mold base 1, the lower surface of the upper mold base 1 is fixedly connected with an upper backing plate 2, and the lower surface of the upper backing plate 2 is fixedly connected There is a fixed plate 3, a discharge cover 4 is arranged below the fixed plate 3, a gap is provided between the lower surface of the fixed plate 3 and the upper surface of the discharge cover 4, and the lower surface of the discharge cover 4 is fixed An upper splint is connected, the lower surface of the upper splint is fixedly connected with a discharge plate 5, and the left and right sides of the fixed plate 3 are fixedly connected with a connecting device, and the connecting device includes a longitudinal part, and the lower part of the longitudinal part is horizontally upward to splint The direction extends out of the transverse part, the length of the discharge cover 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com