Iron pipe cutting machine

A cutting machine and iron pipe technology, applied in metal sawing equipment, sawing machine equipment, metal processing equipment and other directions, can solve the problems of many burrs, uneven sections, and different wall thicknesses of iron pipes, and achieve a smooth cutting section. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

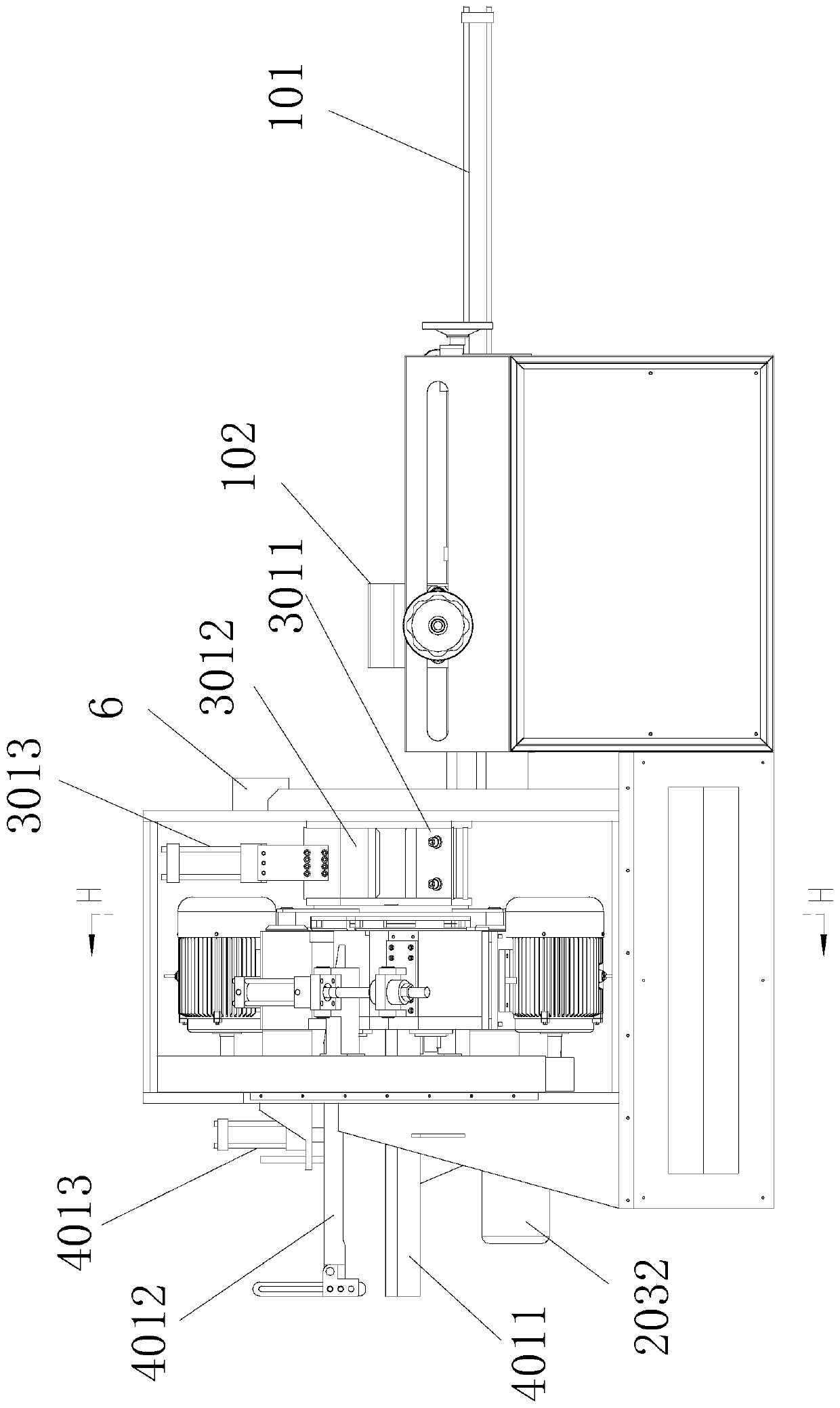

[0022] Embodiment 1: An iron pipe cutting machine, including: a feeding part, a cutting part and a clamping part, wherein,

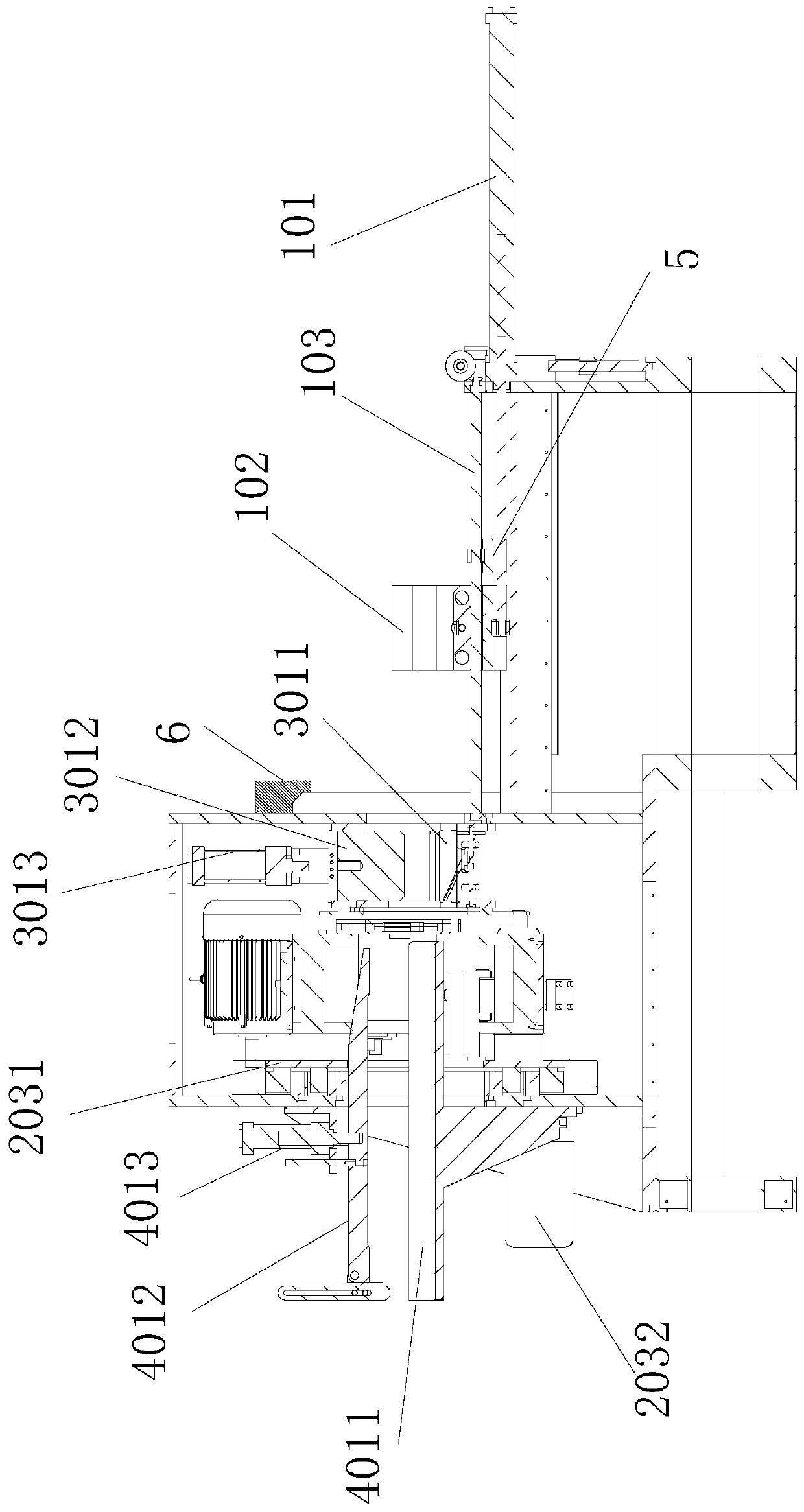

[0023] like figure 1 and figure 2 As shown, the feeding part includes a driving part 101 and a feeding clamping part 102, and the driving part 101 drives the feeding clamping part 102 to reciprocate. In this application, the feeding clamping part 102 is a feeding clamp, which drives Part 101 is a feed oil cylinder, one end of the feed clamp is connected to the feed cylinder, the feed clamp is arranged on the guide rail of the frame, and the feed clamp moves along the guide rail 103 under the drive of the feed cylinder; the feed clamp Specifically, it includes two opposite half clamps 1021, and each half clamp corresponds to a feed clamp cylinder 1022. Under the action of the feed clamp cylinder, the two half clamps move closer to each other or separate from each other. , when it is necessary to clamp the iron pipe for feeding, the two half clamps move...

Embodiment 2

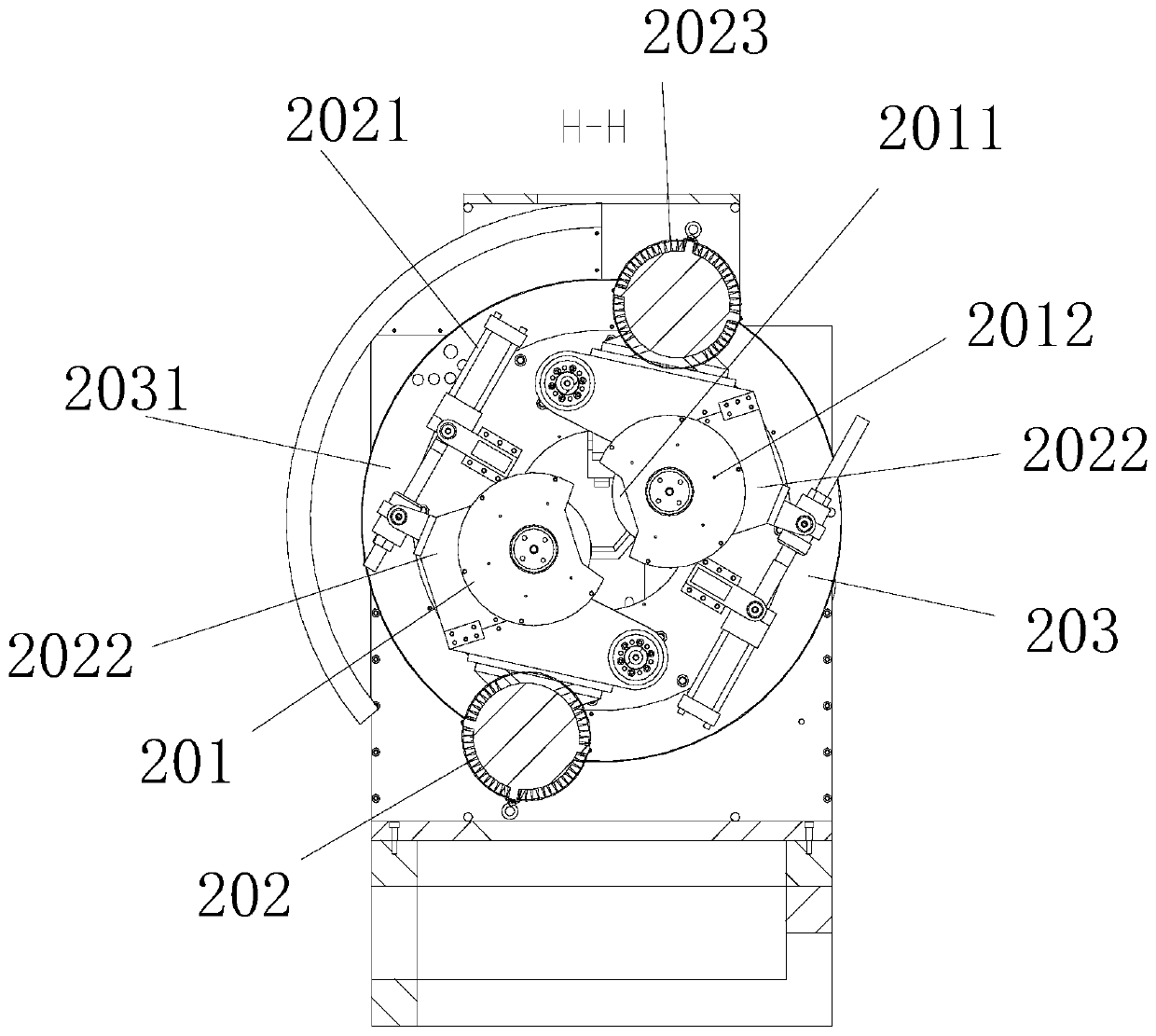

[0027] Embodiment 2: The applicant makes a further design on the basis of Embodiment 1. In order to improve the cutting efficiency, in this embodiment, the cutting parts 201 and the cutting drive part 202 are two groups, and the two groups of cutting parts are arranged opposite to each other. The piece 201 includes a saw blade 2011 and a saw blade guard 2012. The saw blade guard 2012 is sleeved on the saw blade 2011, and the saw blade guard 2012 is provided with a hole for the saw blade to extend out. In this embodiment Using TCT cold saw blade, the diameter can be adjusted Iron pipes with a thickness of 15mm-30mm are cut at high speed. When cutting, the cutting blade driving motor 2023 is started, and the reduction box 2022 is driven to drive the saw blade 2011 in the cutting part 201 to rotate, so as to realize the contact between the saw blade 2011 and the iron pipe to realize cutting; after the saw blade is started, the feed cylinder is started , drive the reduction box ...

Embodiment 3

[0028] Embodiment three: as Figure 4 As shown, the applicant made further research and development on the basis of Embodiment 1 or Embodiment 2. The side guide rail 103 of the feed clamp is also provided with a fixed-length limit seat 4, and the fixed-length limit seat 4 is located at Near the side of the feed oil cylinder, since the feed clamp and the fixed-length limit seat 5 are all arranged on the guide rail 103, and the length of the guide rail is constant, the feed clamp is placed on the guide rail through the fixed-length limit seat. The location of the position is limited, that is, the distance between the feeding clamp and the cutting part is limited. By controlling the distance between the feeding clamp and the cutting part, the length of each iron pipe entering the cutting part is controlled, and the length of the iron pipe is realized. Precise control.

[0029] In this embodiment, a metal non-destructive flaw detection device 6 is also provided between the feedin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com