3D visual guide carton intelligent unstacking and stacking integrated system and unstacking and stacking method

A vision-guided and integrated system technology, applied in the direction of object destacking, object stacking, conveyors, etc., can solve the problems of intelligent depalletizing and stacking obstacles of cartons, and achieve higher production efficiency, save manpower, and improve work efficiency. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

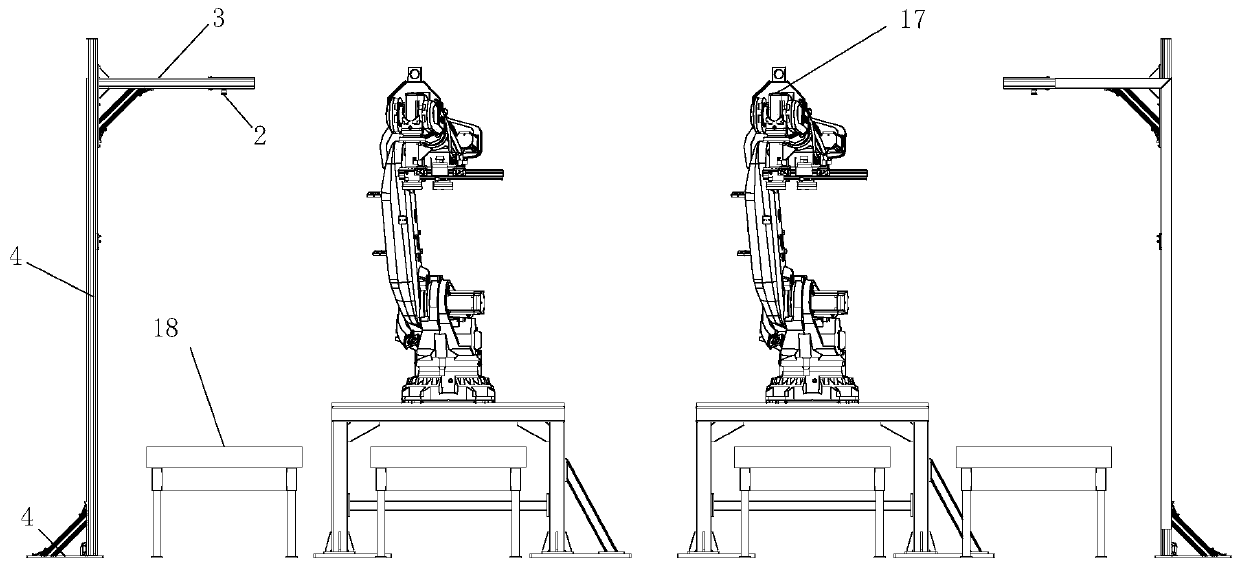

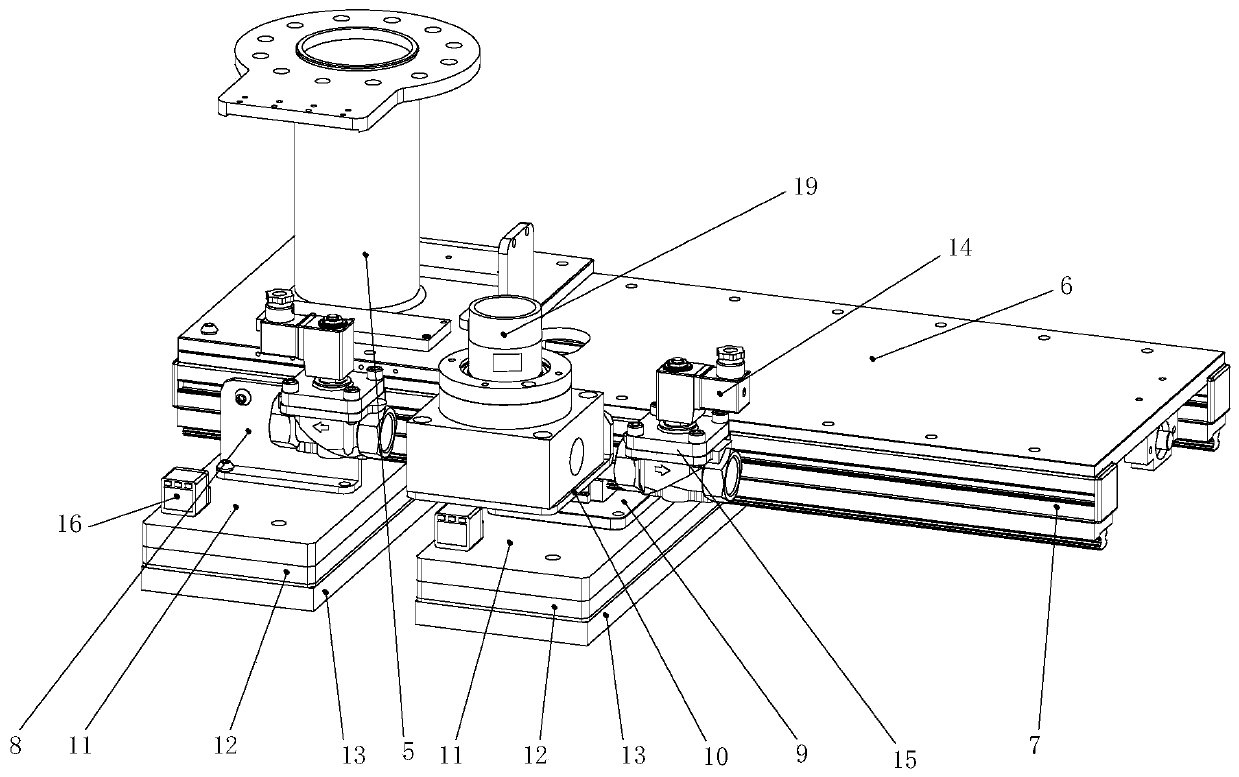

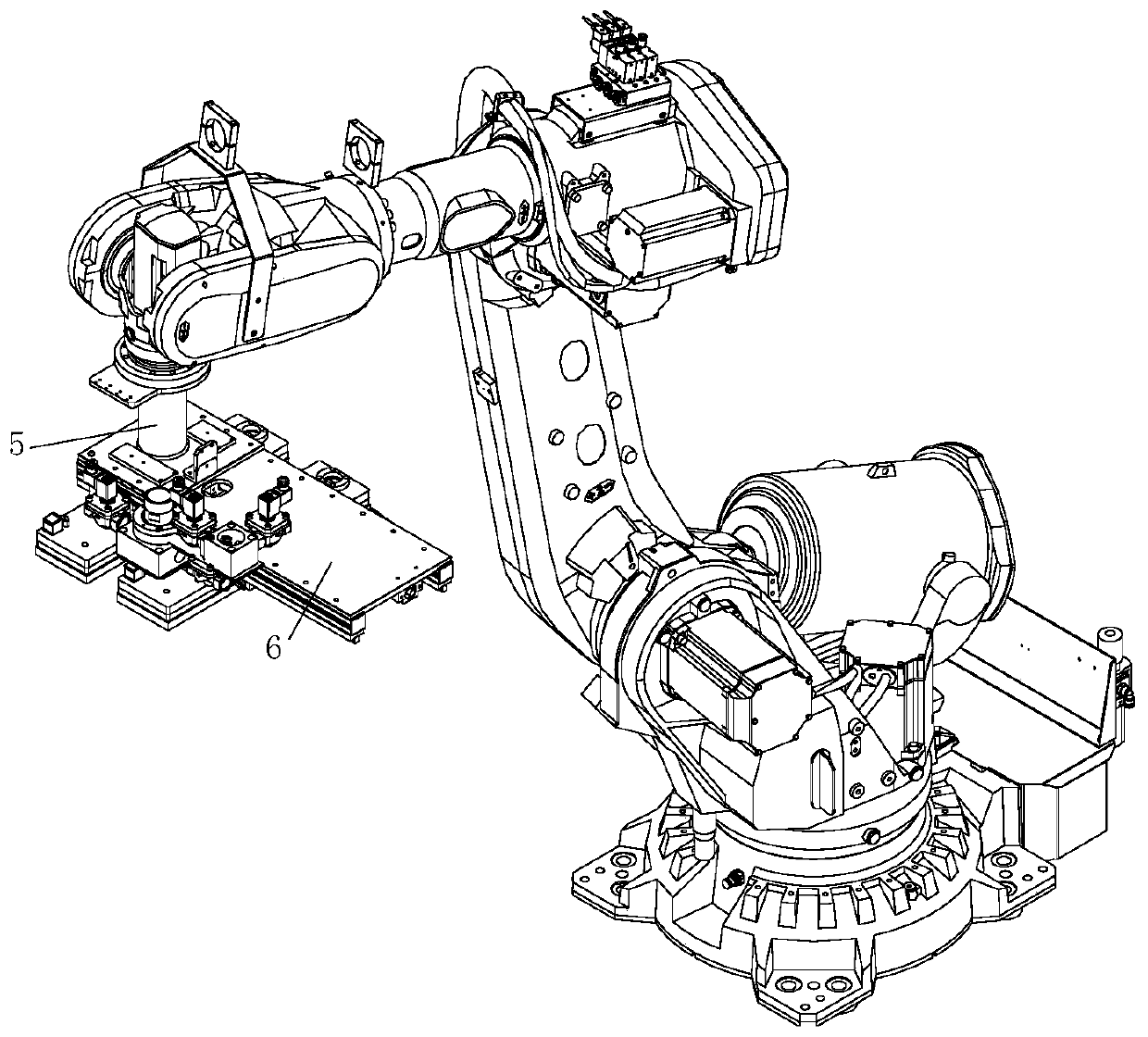

[0026] See Figure 1 to Figure 4 , the present invention comprises carton conveying line 18; Carton conveying line 18 is provided with several conveying pallets; One side of carton conveying line 18 is installed with robot end effector 17 through robot installation flange mechanism; Robot installation flange mechanism includes connecting flange 5. Mounting panel 6, beam 7, fixed mounting plate 8, mobile mounting plate 9 and nut flange plate 10, connecting flange 5 and mounting panel 6 are fixedly connected; fixed mounting plate 8 and mobile mounting plate 9 are fixed to the beam 7 connected, and the fixed mounting plate 8 and the mobile mounting plate 9 are connected with a corresponding vacuum gripper system; the nut flange plate 10 and the mobile mounting plate 9 are fixedly connected, and a vacuum generator 19 is installed on the upper end of the nut flange plate 10.

[0027] The other side of the carton conveying line is equipped with a 3D vision system; the 3D vision syst...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap