Expansion type double-station turning frame for cleaning frame in seat lining processing procedure

A cleaning equipment and double-station technology, which is applied in the processing of textile materials, textiles and papermaking, and the processing of textile material carriers, etc., can solve the problems of limited cleaning quantity, affecting sales, bushing damage, etc., and achieve good cleaning effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

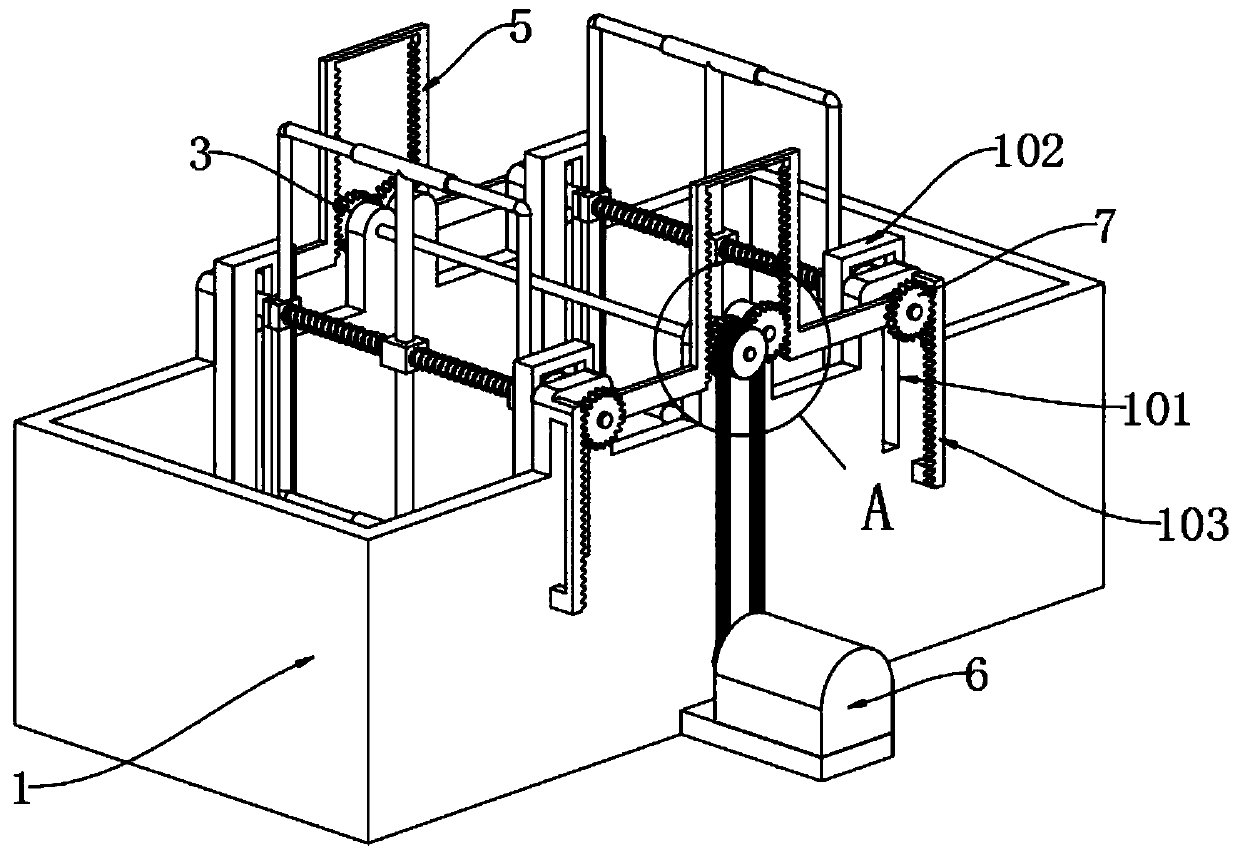

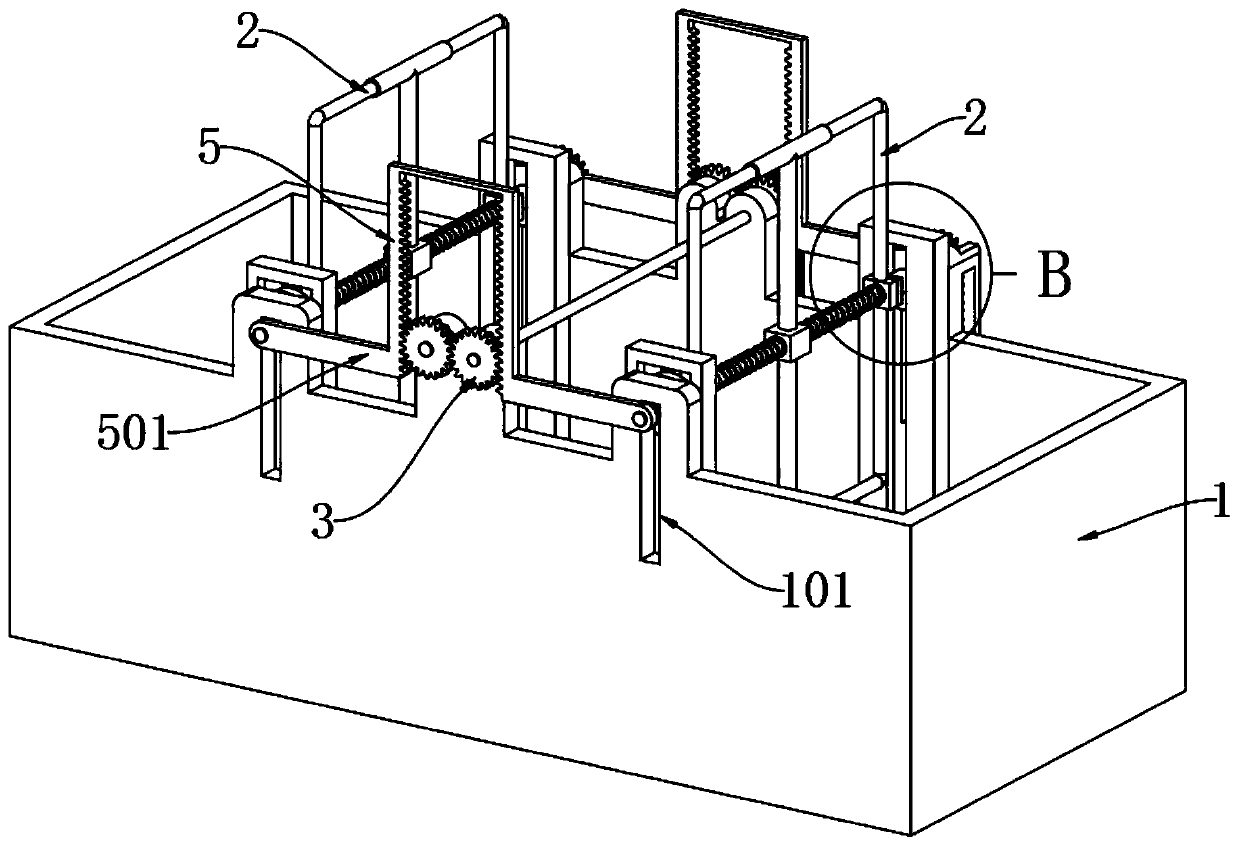

[0025] as attached figure 1 to attach Figure 5 Shown:

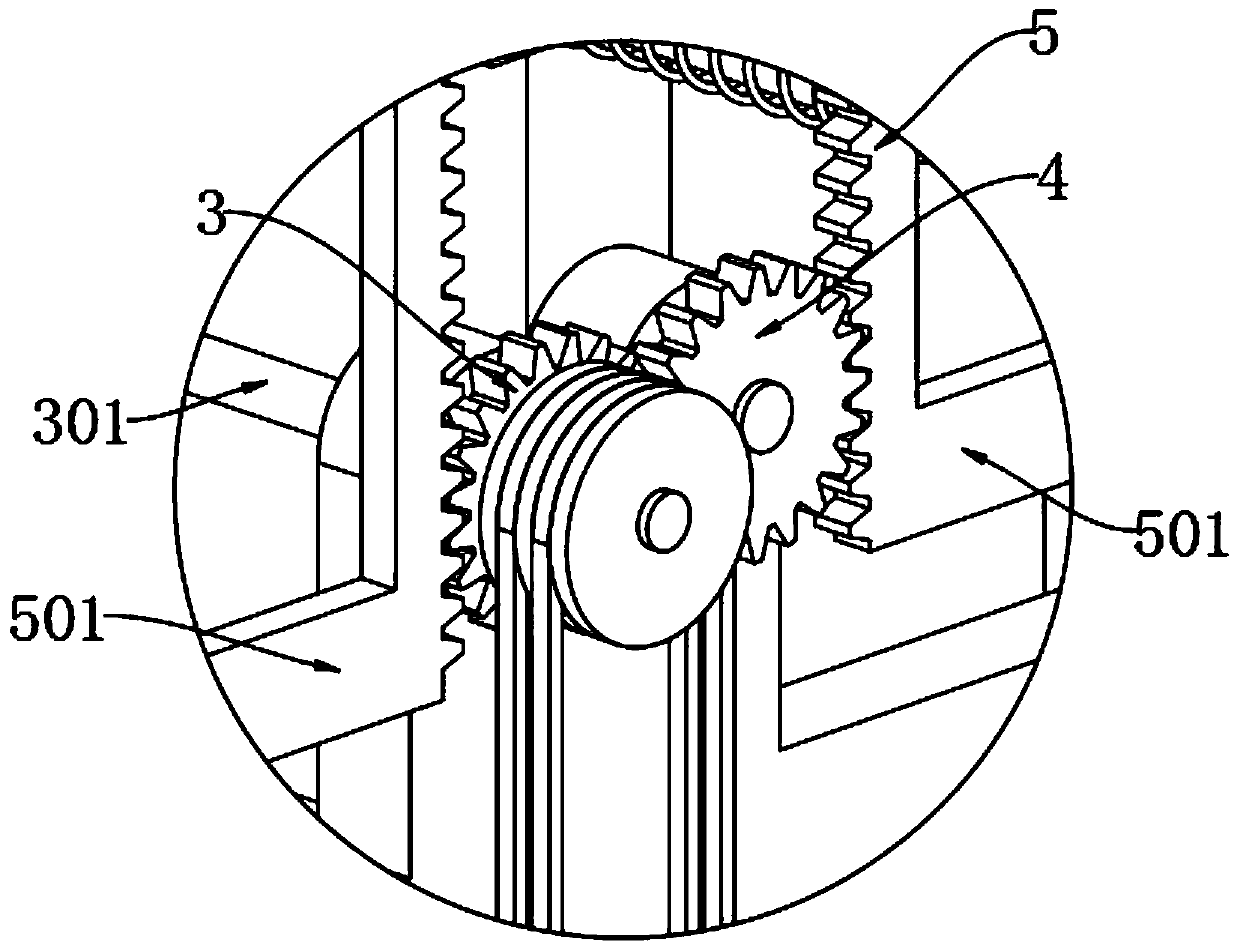

[0026] The present invention provides an expansion-type double-station overturn frame for cleaning equipment in the processing of seat bushings, which includes a cleaning pool 1; 2. There are two groups, which are slidably inserted into the slide bar hole 101 respectively. Two groups of driving gears 3 are installed in the middle of the cleaning tank 1, and the same side of the driving gear 3 is meshed with driven gears 4 respectively. The driving gears 3 are clamped by the connecting shaft 301, and the outer end of the connecting shaft 301 is rotationally connected with the driving motor 6 through the pulley and the V-belt. Lifting rack frame 5.

[0027] Wherein, the expansion mechanism 2 also includes an outer shaft 201, a clamping circular plate 202, an adjustment shaft 203, a U-shaped adjustment strut 204, an I-shaped intubation tube 205 and a spring 206, and the outer shafts 201 are respectively arranged on the e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap