A pipeline impingement jet uniform aeration generating device

A technology of impinging jet and gas generation, which is applied to hydraulic models and other directions to achieve the effect of increasing radial turbulence and improving the effect of aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

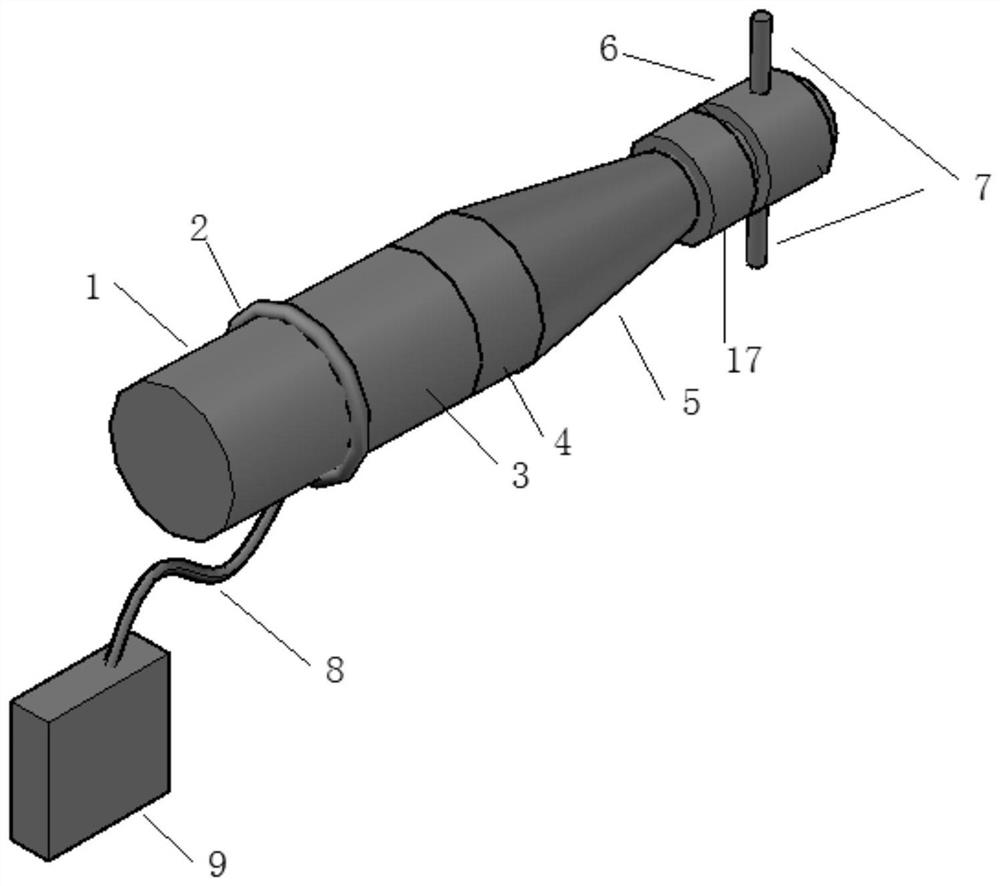

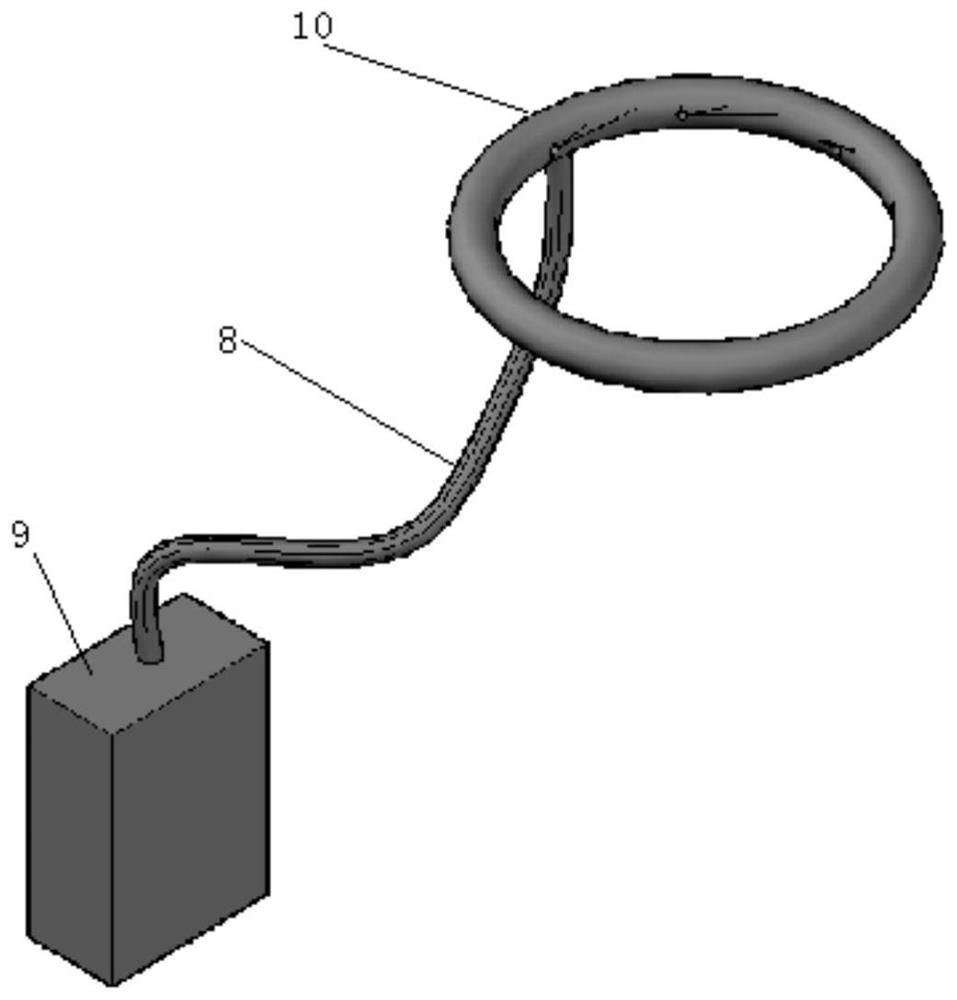

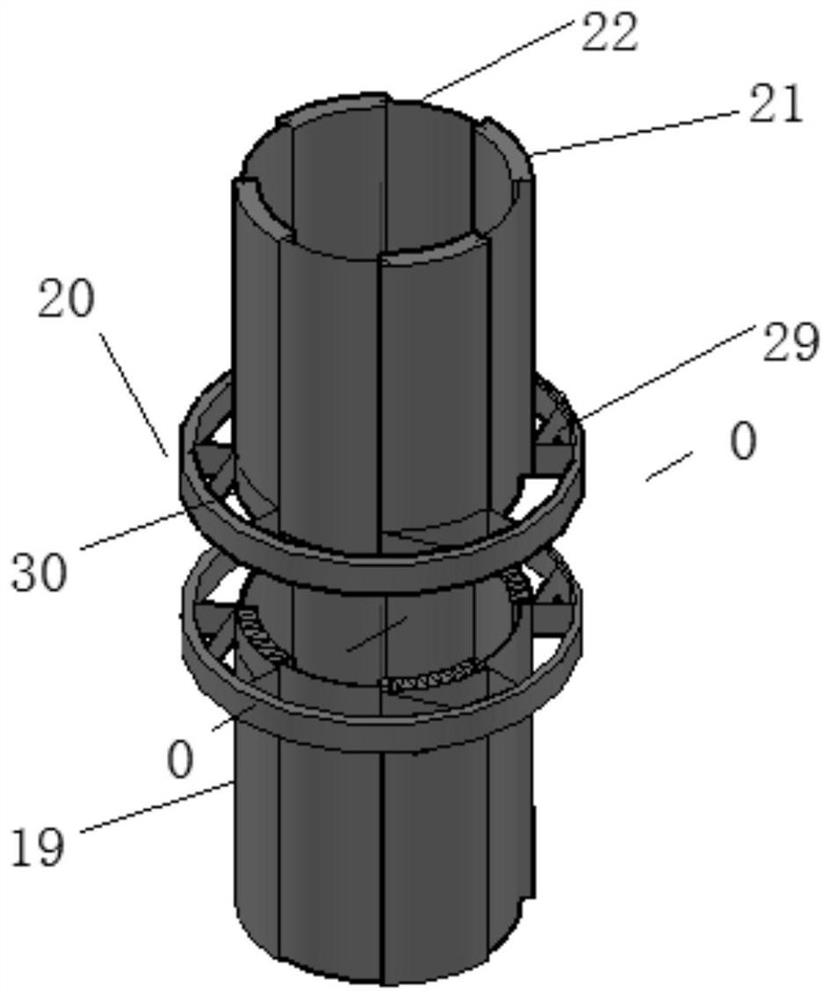

[0029] Such as Figure 1 to Figure 15 As shown, the pipeline impact jet uniform aeration generating device of the present invention includes an inlet section 1, an aeration generation section 2, a transition section 3, a steady flow section 4, a contraction section 5 and a measurement section 6 connected in sequence, and the inlet section 1. Connect the aeration generation section 2 and the incoming water pipeline, the aeration generation section 2 is welded to the transition section 3, the transition section 3, the steady flow section 4, the contraction section 5 and the measurement section 6 are all connected by threads; the measurement section 6 includes The first outer sleeve 11, the middle sleeve 12, the first inner sleeve 13, the shrinkable round tube 16, the steel ball 14, the first spring, the β-ray aeration concentration meter 7, the first outer sleeve 11, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com