Sealing device and hub driving device

A technology of sealing device and sealing lip, which is applied in the direction of transmission parts, engine sealing, engine components, etc., can solve the problems of large instantaneous impact of sealing lip, insufficient spring force, and affecting dynamic sealing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

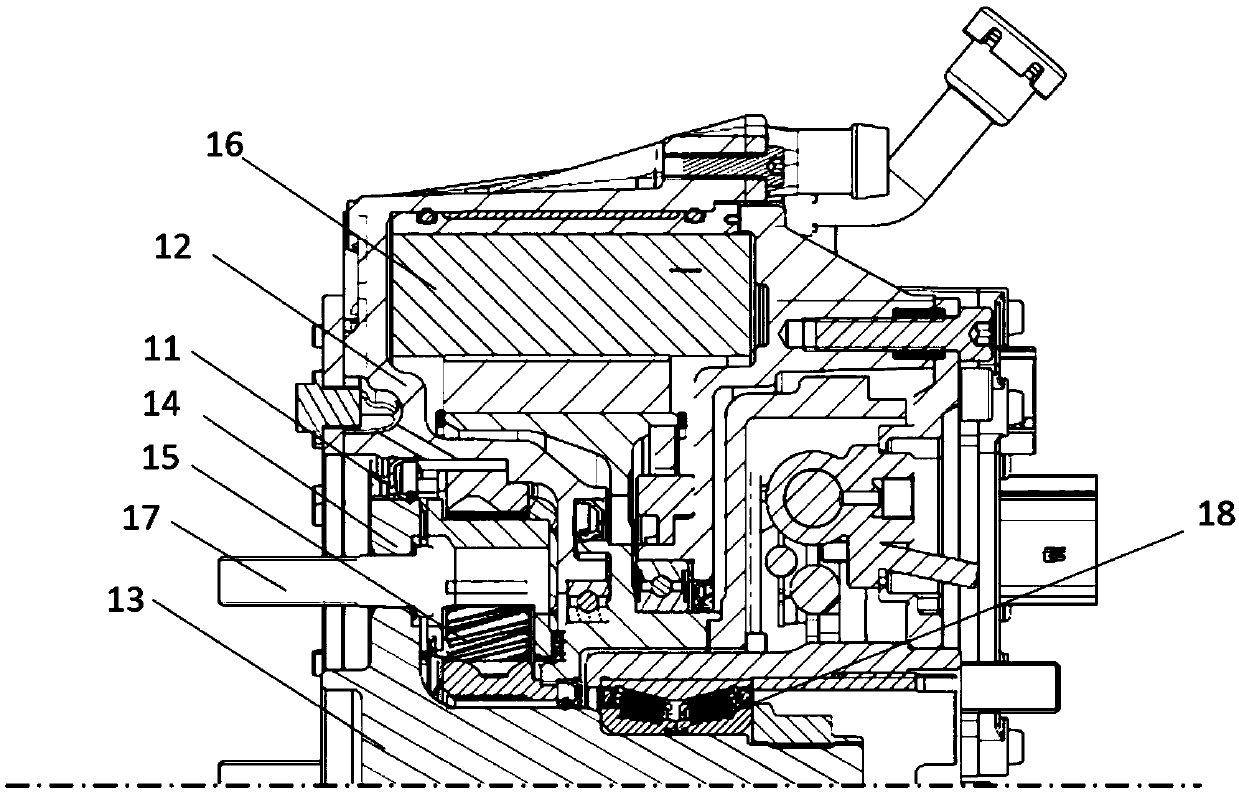

[0020] figure 1 A half-sectional view of a wheel hub drive according to the invention is shown. The wheel hub driving device includes a wheel hub (not shown) for supporting vehicle tires, a flange shaft 13, a hub bearing 18 supporting the flange shaft 13, a speed reducer 15, a motor, a motor housing 12 for holding and a seal device 11. In the motor housing 12 is mounted an electric motor with a rotor 16 , which drives a flange shaft 13 via a reduction gear 15 , and a hub bearing 18 is arranged between the flange shaft and the hub drive housing. The flange shaft 13 has a flange disc 14 at the end, and a plurality of screw rods 17 are arranged on the flange disc 14, and these screw rods 17 are evenly distributed on the circumference of the flange disc 14, and the screw rods 17 are fixedly connected with the hub, so that The flange shaft 13 is fixedly connected with the hub. When the rotor 16 of the motor rotates the flange shaft 13 through the reducer 15 made of planetary gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com