Magnetoelectric rotation speed generator

A magnetoelectric sensor and generator technology, which is applied in the direction of instruments, electromechanical devices, electrical components, etc., can solve the problems of inability to simulate the engine speed signal, amplitude increase, etc., and achieve the speed signal source is true and reliable, the structure is simple, and the scope of application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

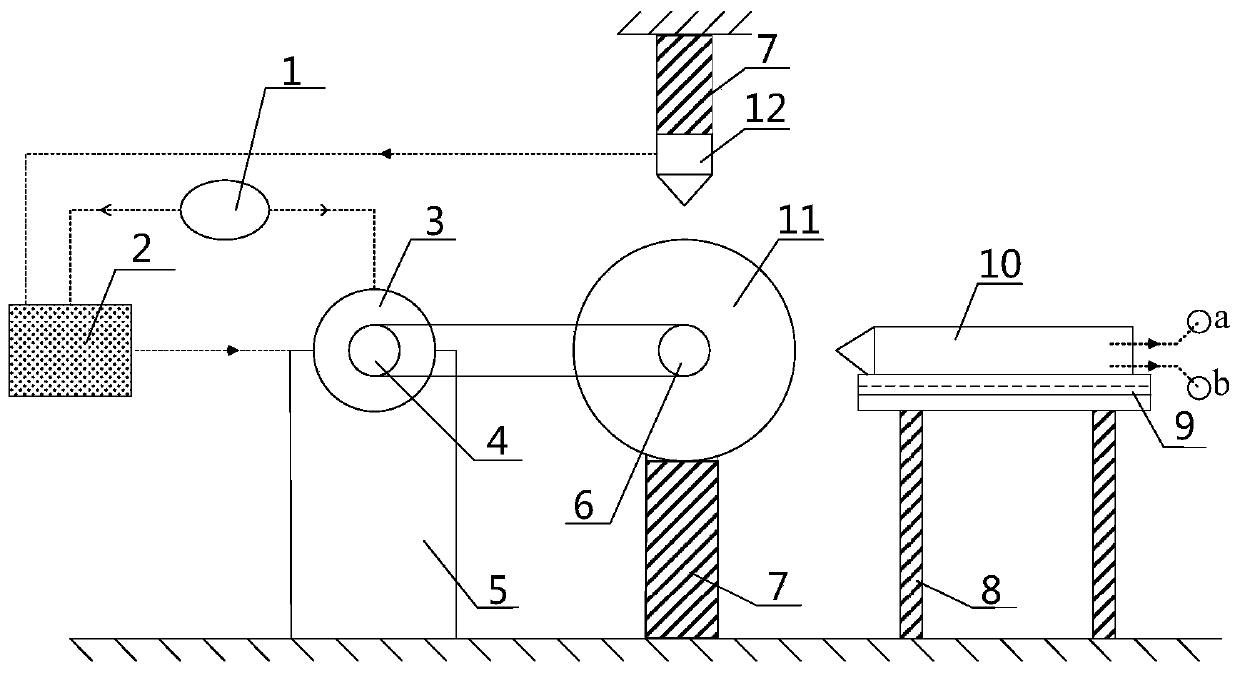

[0019] combine Figure 1-3 , the magnetoelectric speed generator of the present invention includes a brushless DC motor 3, a magnetic gear 11, a magnetoelectric sensor 10, a Hall sensor 12, a rotary axial displacement device 9, a PID controller 2, a battery pack 1, a chain Wheel Ⅰ4, sprocket Ⅱ6, fixed bracket, etc. The battery pack 1 transmits electric energy to the PID controller 2 and the brushless DC motor 3 through the circuit, the PID controller 2 is connected with the brushless DC motor 3 through the circuit, and the power output end of the brushless DC motor 3 is coaxially connected with the sprocket I4, The magnetic gear 11 is coaxially connected with the sprocket Ⅱ6, and the sprocket Ⅰ4 and the sprocket Ⅱ6 are connected through a transmission chain. The number of teeth of the two sprockets is equal, and the transmission ratio is 1:1. The motor is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com