Fuel cell thermal management test system and test method

A test system and fuel cell technology, applied in the direction of fuel cells, circuits, measuring electronics, etc., can solve the problems of low analysis efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention is further illustrated below by means of examples, but the present invention is not limited thereto within the scope of examples.

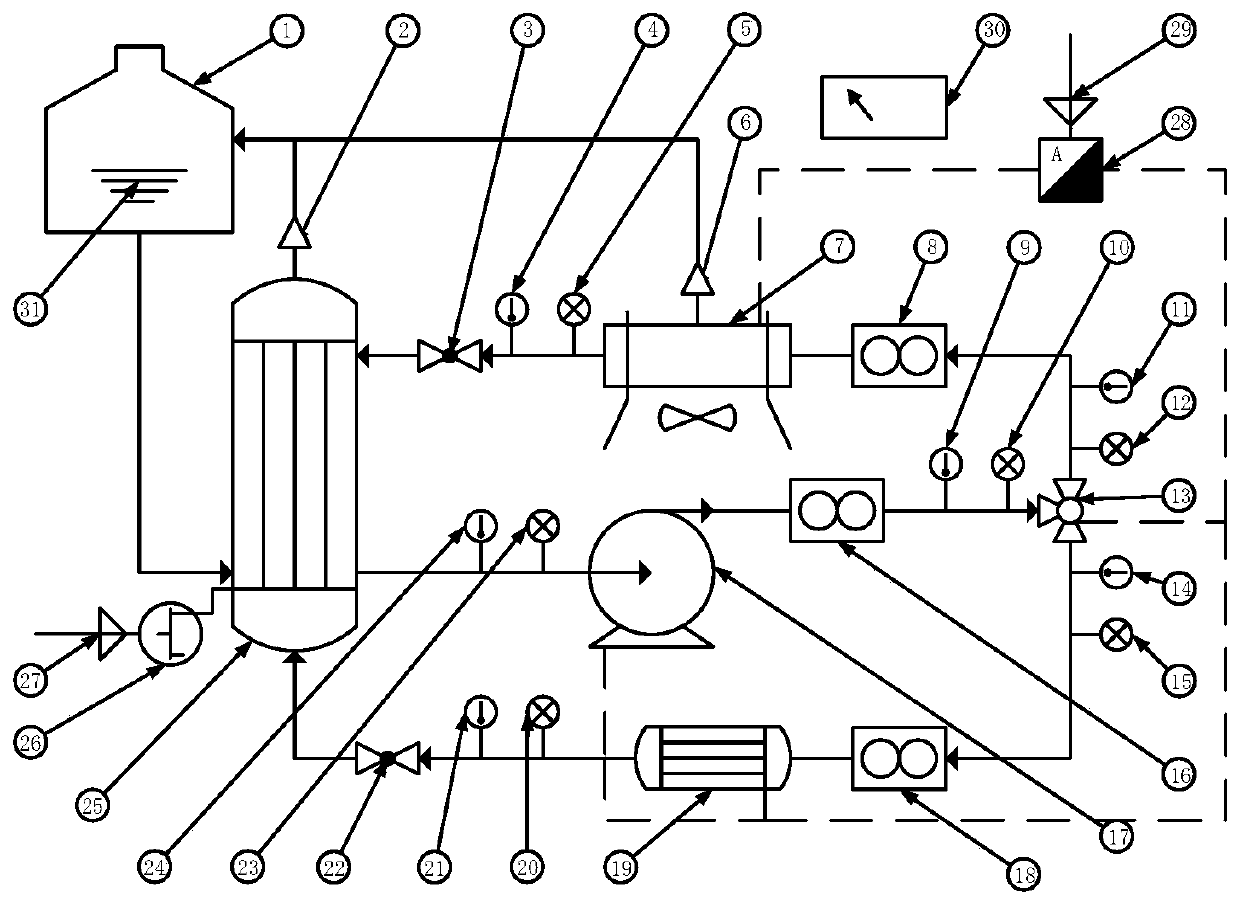

[0077] This implementation discloses a fuel cell thermal management test system, such as figure 1 As shown, the fuel cell thermal management test system includes: a liquid storage tank 1 , a stack simulator, a thermostat 13 , a booster pump 17 , a heater 19 and a radiator 7 . Wherein, the liquid storage tank 1 is used for storing the cooling liquid 31 . The stack simulator is used to simulate the stack under the working condition to be tested. The stack simulator has a liquid inlet, a liquid outlet, a first return port and a second return port connected to each other, and the liquid inlet and the liquid storage tank 1 outlet is connected by pipeline. The thermostat 13 has an inlet, a first outlet and a second outlet. The inlet of the booster pump 17 is connected with the liquid outlet, and the booster pump 17 is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com