Periscopic lifting camera assembly and electronic equipment

A camera and periscope technology, applied in the field of cameras, can solve the problems of slow lifting speed, damage, complex structure, etc., and achieve the effect of avoiding conductive damage, avoiding equipment damage, and fast moving structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

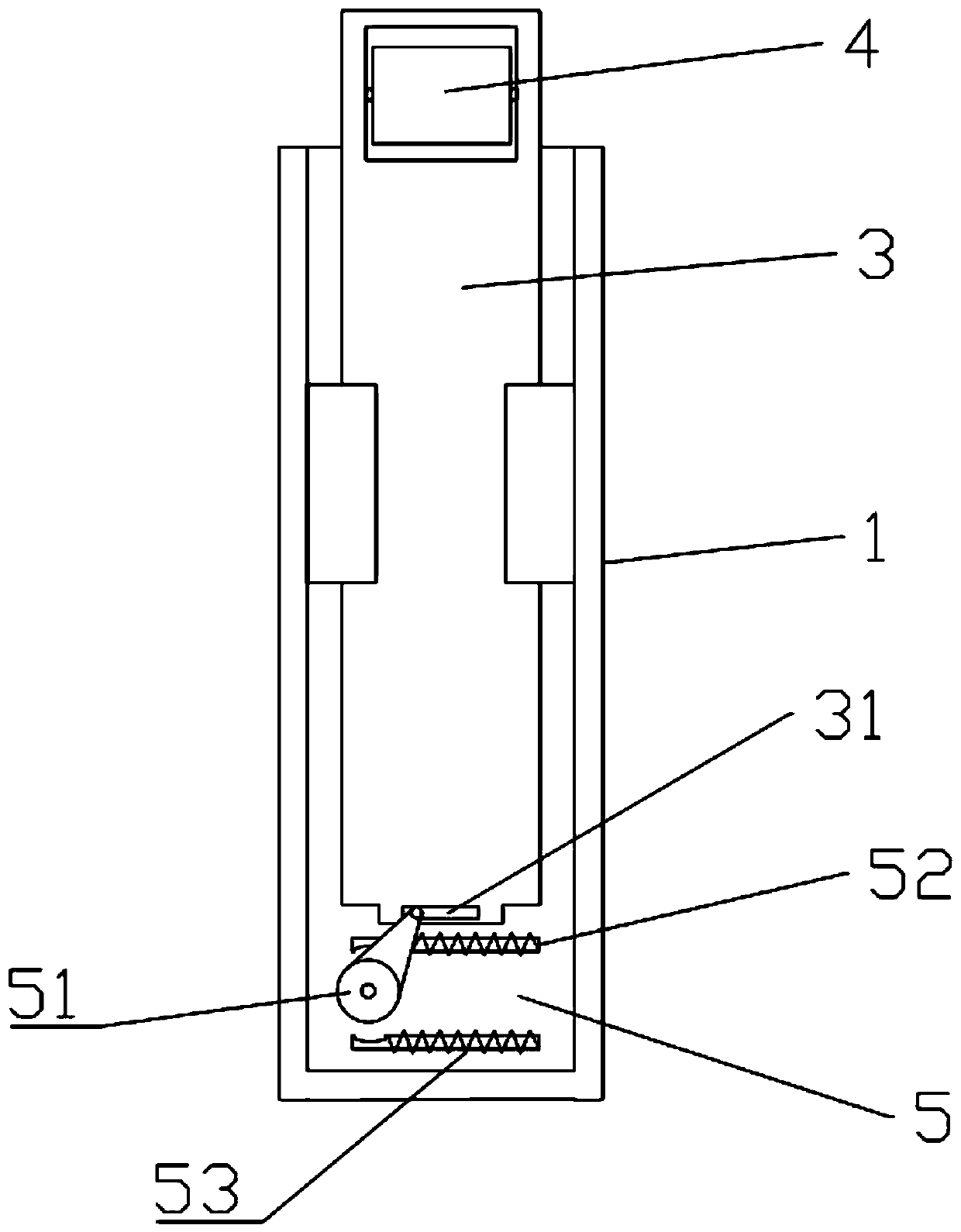

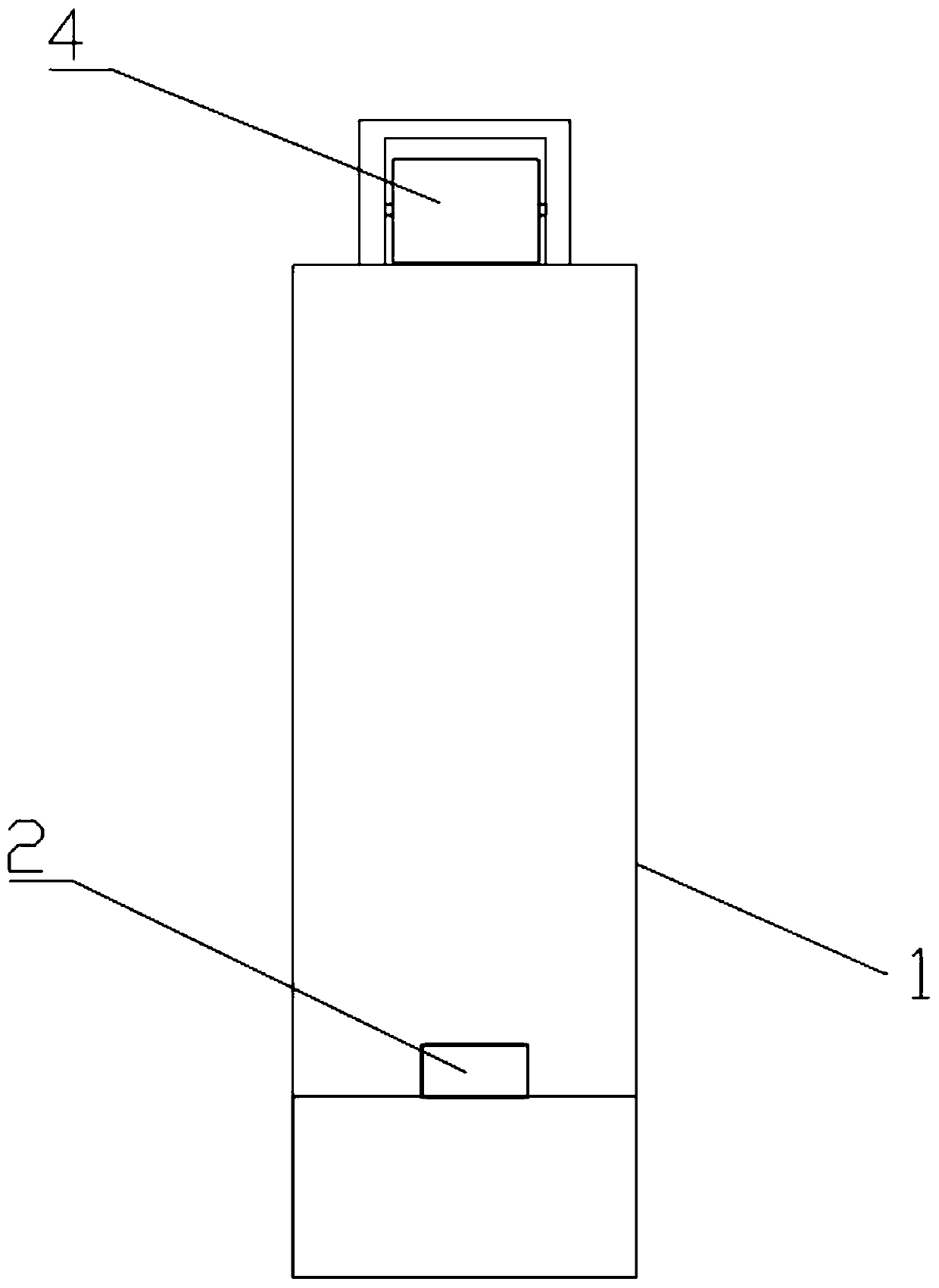

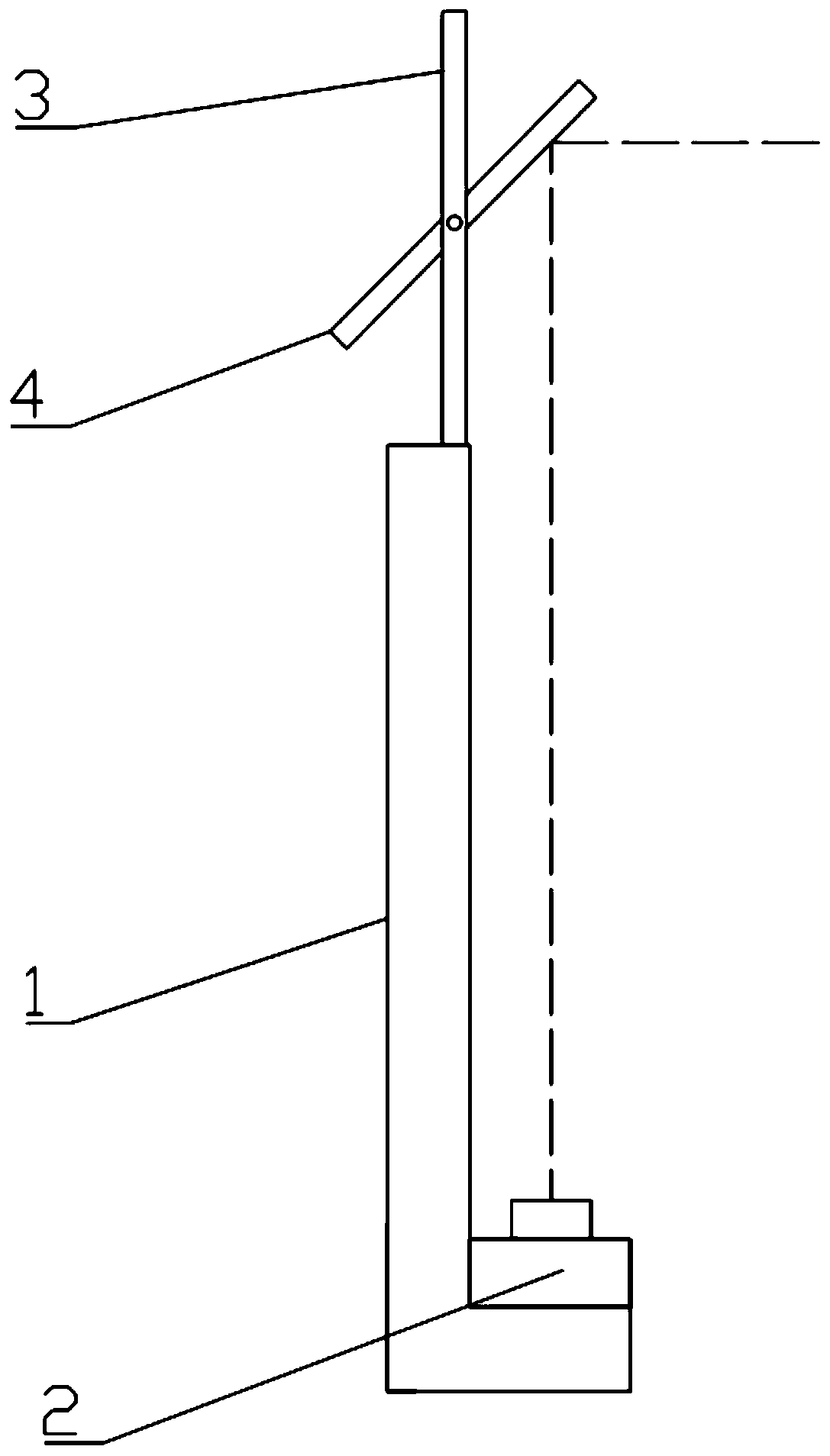

[0031] Such as figure 1 and figure 2 As shown, the periscope lifting camera assembly provided by Embodiment 1 of the present invention includes a base 1 , a camera 2 , a moving piece 3 , a first reflective piece 4 and a first magnetic drive device 5 . The base 1 is in the shape of a cuboid as a whole, and its upper end and front end are opened and formed with grooves. The moving piece 3 is a rectangular plate whose shape and size match the groove, so that it can be placed in the groove and move up and down freely. In order to keep the moving piece 3 moving more stably in the groove, there are vertically parallel sliding grooves on both sides of the groove in this embodiment. Avoid offsetting its movement path. A boss is provided at the bottom of the rear end of the base 1, and the camera 2 is mounted on the boss facing upwards. Such as image 3 As shown, the first reflective sheet 4 is installed on the upper end of the movable sheet 3, and it is inclined at a certain ang...

Embodiment 2

[0036] Compared with embodiment one, embodiment two differs in that: as Figure 10 As shown, the camera 2 is installed obliquely at a certain angle. The periscope lifting camera assembly also includes a second reflective sheet 6 installed on the base 1. The light reflected by the first reflective sheet 4 is reflected twice by the second reflective sheet 6. Enter 2. This installation method makes the thickness occupied by the camera smaller, which is conducive to reducing the thickness of the camera installed on the device when the camera assembly is installed on the electronic device, so that the electronic device can be made thinner. The periscope lifting camera assembly also includes an inductive obstacle avoidance device connected to the first magnetic force drive device, and the inductive obstacle avoidance device is used to send a signal to the first magnetic force drive device when an obstacle occurs above the moving sheet 3, so that the first magnetic force drive The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com