Adaptable aerosol-generating system

An aerosol generation, aerosol technology, applied in applications, electrical components, other medical devices, etc., can solve problems such as hot spots, inconsistent heating, damage, etc., to achieve the effect of improving ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

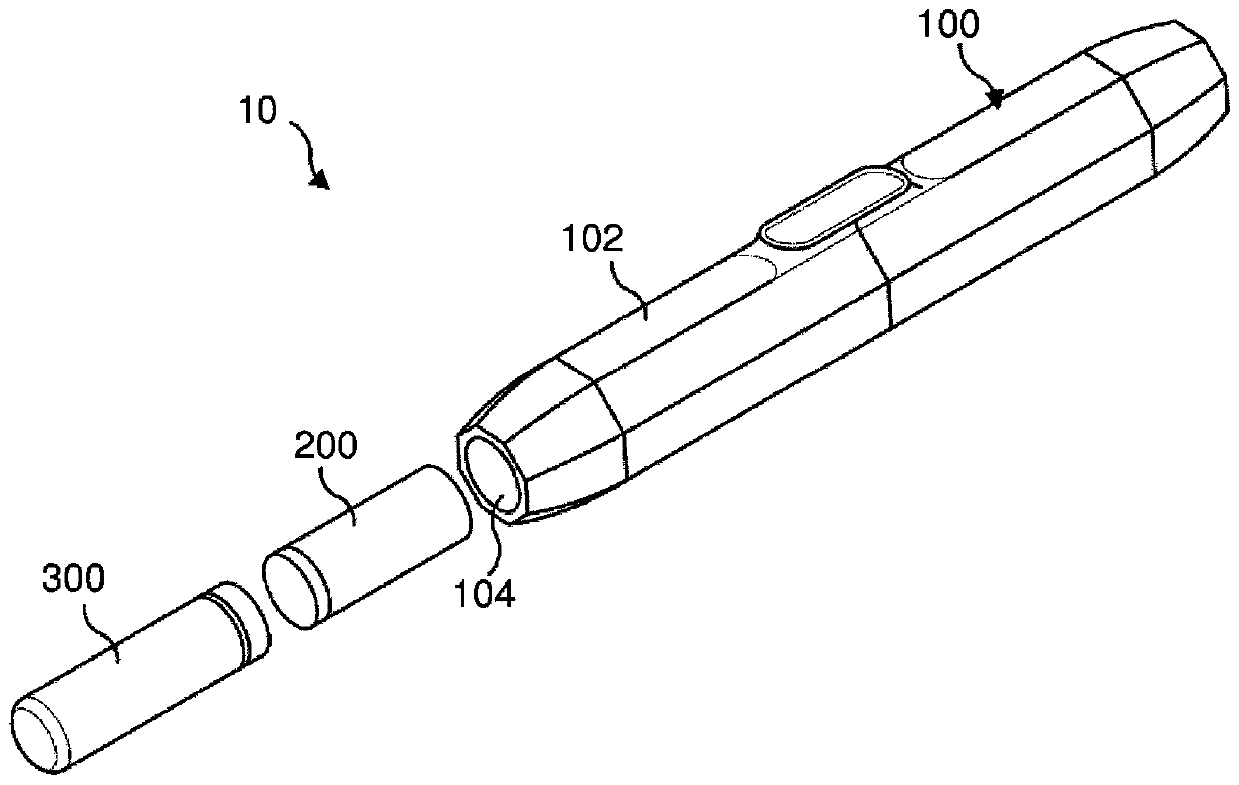

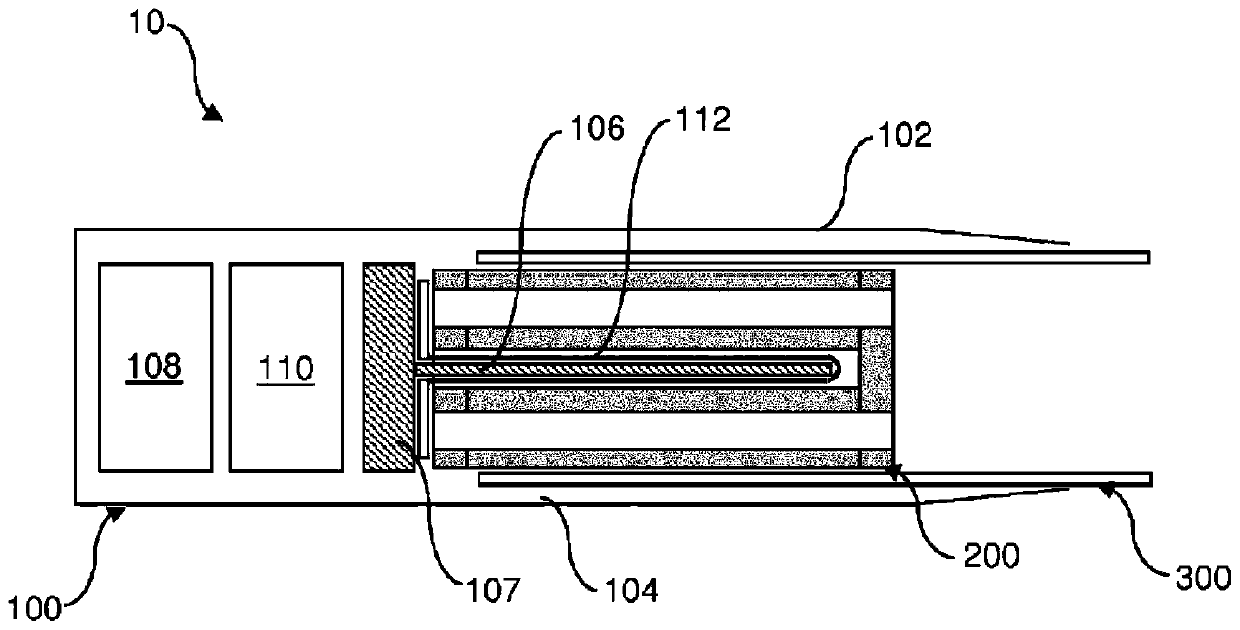

[0247] figure 1 A schematic illustration of an aerosol generating system 10 according to the invention is shown for generating an aerosol comprising nicotine lactate particles. The aerosol generating system 10 includes an aerosol generating device 100 , a cartridge assembly 200 and a mouthpiece 300 .

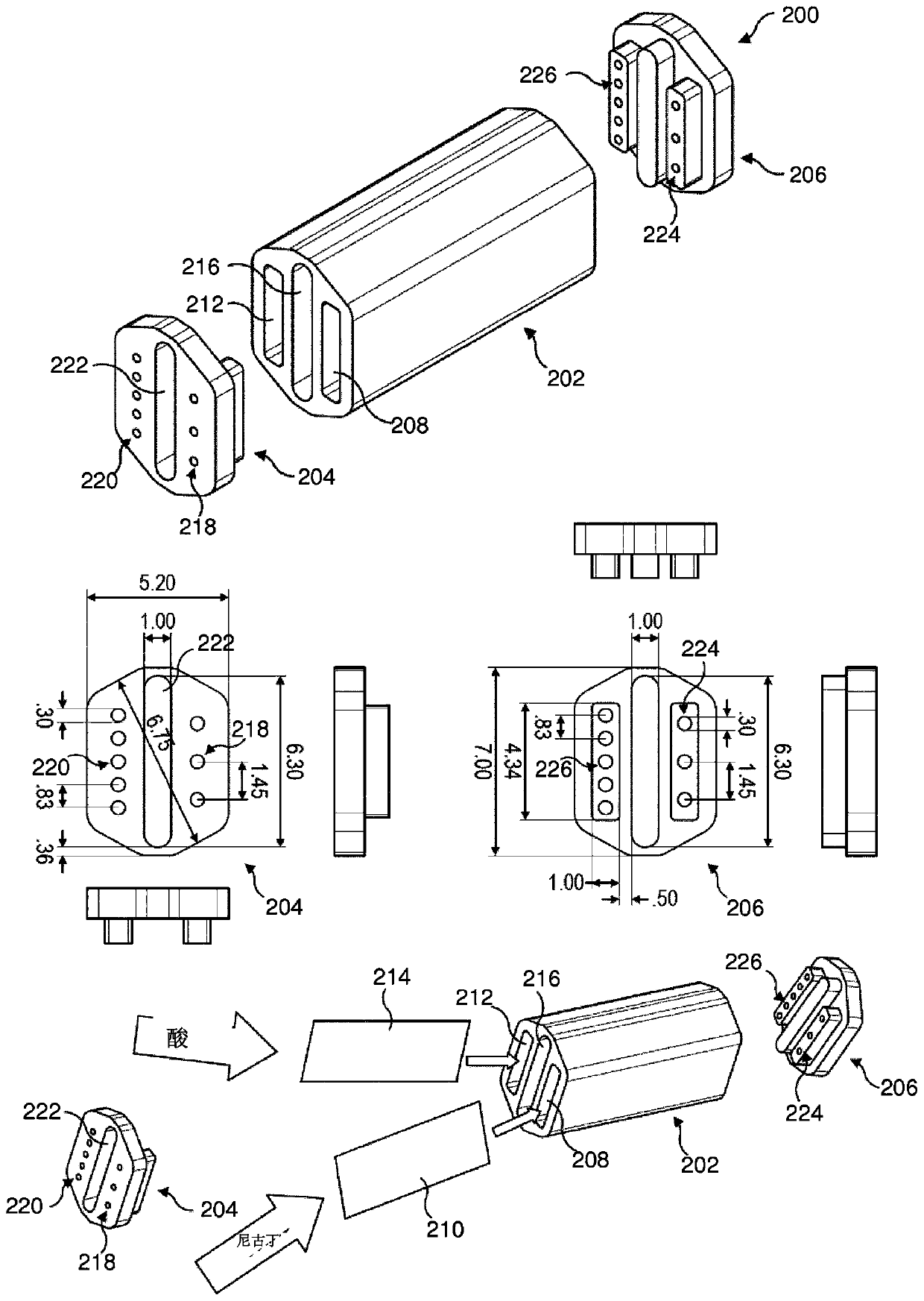

[0248] figure 2 shows the use in figure 1 A schematic illustration of the cartridge assembly 200 of the aerosol generating system. Cartridge 200 includes an elongated body 202, a distal end cap 204, and a proximal end cap 206, and has a length of about 15 millimeters, a width of about 7 millimeters, and a height of about 5.2 millimeters. Body 202 has a length of about 13 millimeters, a width of about 7 millimeters, and a height of about 5.2 millimeters. Distal end cap 204 and proximal end cap 206 each have a length of about 2 millimeters, a width of about 7 millimeters, and a height of about 5.2 millimeters.

[0249] Cartridge 200 includes an elongated first compartment 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com