Bottled beverage detection and sorting device

A sorting device and beverage technology, applied in sorting and other directions, can solve problems such as affecting product quality, intricate and imperfect bottled beverage processing, etc., and achieve the effect of increasing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

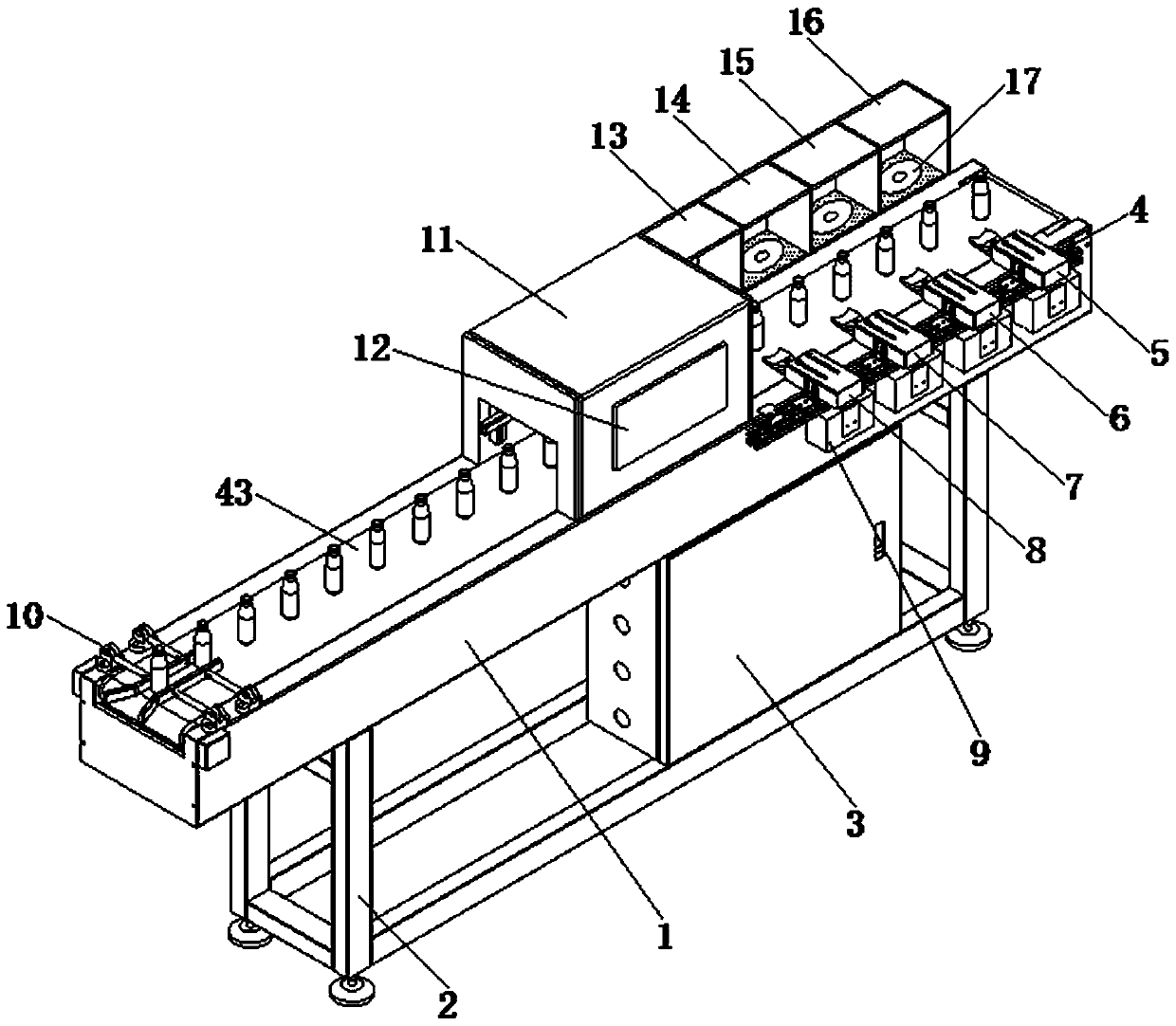

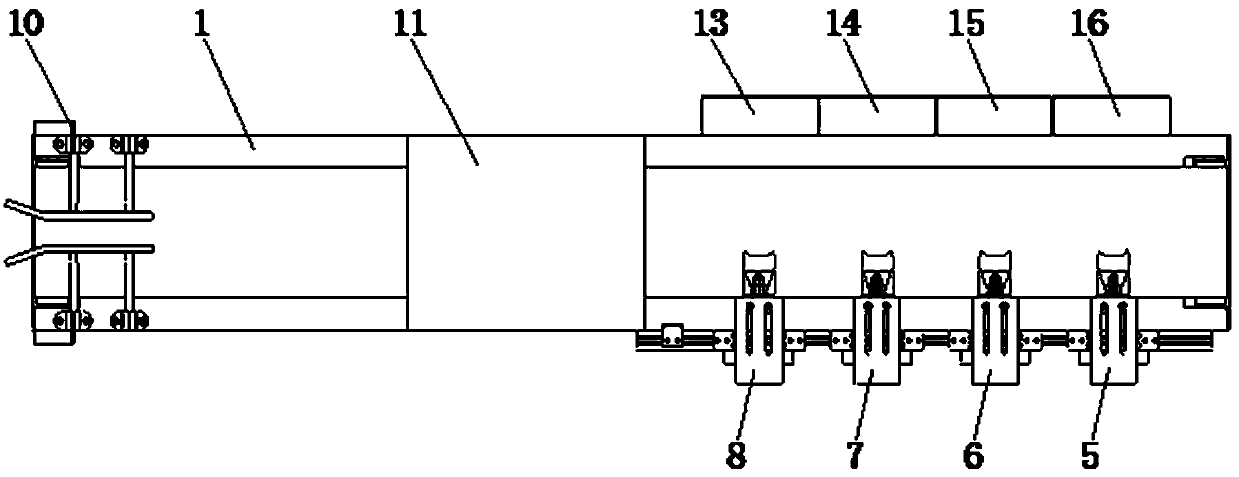

[0033] Such as figure 1 As shown, a bottled beverage detection and sorting device includes a workbench 1 and a support frame 2. The workbench 1 is fixedly installed on the upper end of the support frame 2. The upper end of the workbench 1 is provided with a conveyor belt 43, one side of the upper end of the workbench 1 is provided with a feeding limit device 10, a detection box 11 is fixedly installed in the middle of the upper end of the workbench 1, and a sorting box 11 is fixedly installed on the other side of the upper end of the workbench 1. Device and collection device, the collection device includes No. 4 collection box 13, No. 3 collection box 14, No. 2 collection box 15 and No. 1 collection box 16; the bottled beverage to be detected is conveyed to the detection box 11 through the conveyor belt 43, and the internal camera is triggered Take photos to check whether they are qualified by vision, and then reject and collect unqualified products.

[0034] Such as figure ...

Embodiment 2

[0037] Such as figure 1 As shown, a bottled beverage detection and sorting device includes a workbench 1 and a support frame 2. The workbench 1 is fixedly installed on the upper end of the support frame 2. The upper end of the workbench 1 is provided with a conveyor belt 43, one side of the upper end of the workbench 1 is provided with a feeding limit device 10, a detection box 11 is fixedly installed in the middle of the upper end of the workbench 1, and a sorting box 11 is fixedly installed on the other side of the upper end of the workbench 1. Device and collection device, the collection device includes No. 4 collection box 13, No. 3 collection box 14, No. 2 collection box 15 and No. 1 collection box 16; the bottled beverage to be detected is conveyed to the detection box 11 through the conveyor belt 43, and the internal camera is triggered Take photos to check whether they are qualified by vision, and then reject and collect unqualified products.

[0038] Such as figure ...

Embodiment 3

[0042] Such as figure 1 As shown, a bottled beverage detection and sorting device includes a workbench 1 and a support frame 2. The workbench 1 is fixedly installed on the upper end of the support frame 2. The upper end of the workbench 1 is provided with a conveyor belt 43, one side of the upper end of the workbench 1 is provided with a feeding limit device 10, a detection box 11 is fixedly installed in the middle of the upper end of the workbench 1, and a sorting box 11 is fixedly installed on the other side of the upper end of the workbench 1. Device and collection device, the collection device includes No. 4 collection box 13, No. 3 collection box 14, No. 2 collection box 15 and No. 1 collection box 16; the bottled beverage to be detected is conveyed to the detection box 11 through the conveyor belt 43, and the internal camera is triggered Take photos to check whether they are qualified by vision, and then reject and collect unqualified products.

[0043] Such as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com