Core-surface gradient nitrogen oxide fluorescent powder, preparation method thereof and luminescent device using fluorescent powder

A technology of nitrogen oxides and light-emitting devices, which is applied in chemical instruments and methods, light-emitting materials, semiconductor devices, etc., can solve problems such as poor matching between phosphors and chips, reduced luminous intensity, and poor white light chromaticity, etc., to achieve service life Long-lasting, stable properties and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

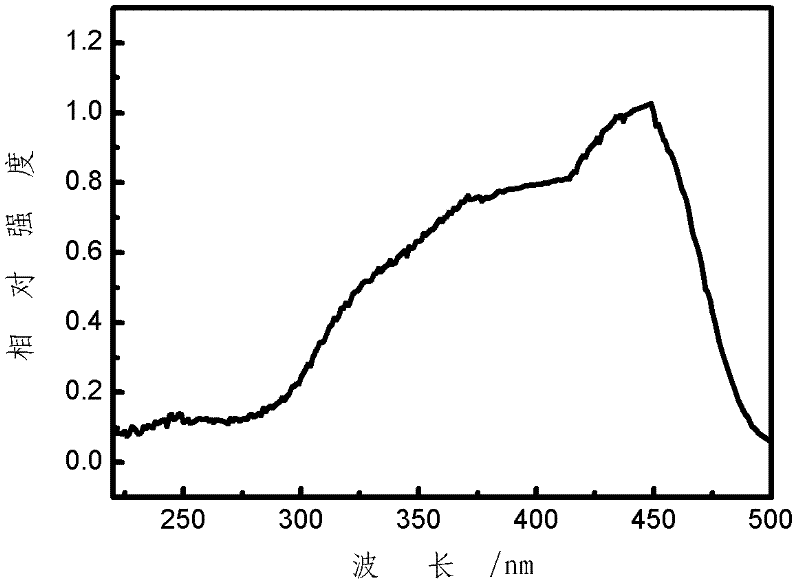

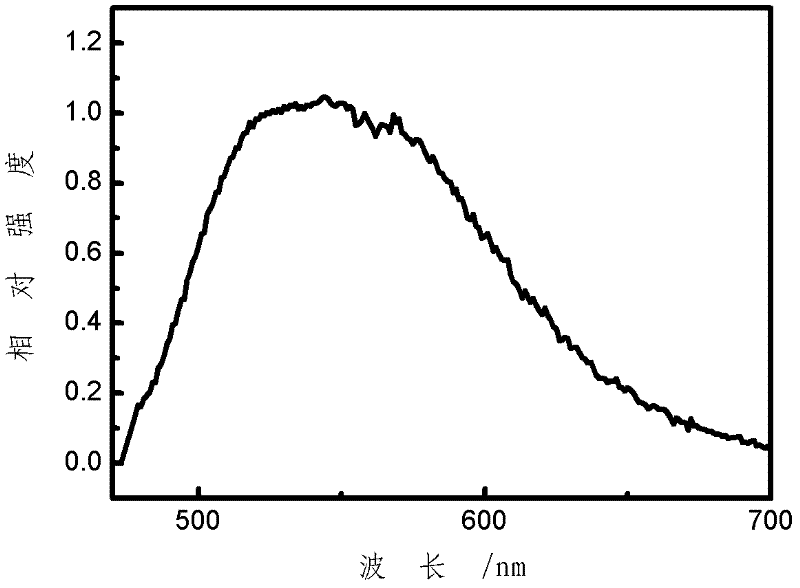

[0044] The chemical formula of the fluorescent powder product of this embodiment is Ca after analysis. 0.94 Si 2 o 2 N 2 :0.06Eu / Ba 0.94 Si 2 o 2 N 2 :0.06Eu. Its manufacturing method is to weigh CaCO respectively according to the stoichiometric ratio 3 (4N), SiO 2 (4N), Si 3 N 4 (4N), Eu 2 o 3 (4N) and BaCO 3 (4N), SiO 2 (4N), Si 3 N 4 (4N), Eu 2 o 3 (4N); Wherein, respectively add 0.5% by weight of raw material total amount CaF 2 (AR) and BaF 2 (AR) is the flux. After mixing and grinding the above raw materials evenly, put them into the molybdenum crucible, and put them in the N at 1400℃ 2 Insulated in the atmosphere for 5 hours, the resulting product was crushed, pickled to remove impurities, sieved, and dried, and the Ba 0.94 Si 2 o 2 N 2 :0.06Eu plasma sprayed on Ca 0.94 Si 2 o 2 N 2 : 0.06Eu surface, that is, the phosphor powder of the present invention. Its excitation and emission spectra are shown in figure 1 and figure 2 , it can be see...

Embodiment 2

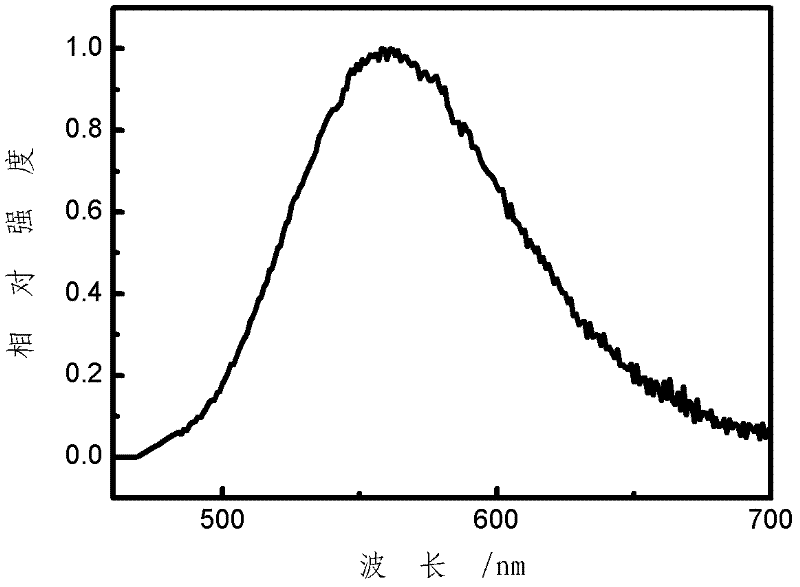

[0051] The chemical formula of the fluorescent powder product of this embodiment is Ca after analysis. 0.94 Si 2 o 2 N 2 :0.06Eu / Sr 0.94 Si 2 o 2 N 2 :0.06Eu. Its manufacturing method is to weigh CaO (4N), SiO respectively according to the stoichiometric ratio 2 (4N), Si 3 N 4 (4N), Eu 2 o 3 (4N) and SrO(4N), SiO 2 (4N), Si 3 N 4 (4N), Eu 2 o 3 (4N); Wherein, respectively add 5% by weight of raw material total amount NH 4 Cl(AR), put the above raw materials into a molybdenum crucible after mixing and grinding evenly, at 1600°C in H 2 / N 2 Insulated in the atmosphere for 3 hours, the resulting product was crushed, pickled to remove impurities, settled and classified, dried, and the Sr 0.94 Si 2 o 2 N 2 :0.06Eu PVD on Ca 0.94 Si 2 o 2 N 2 : 0.06Eu surface, namely the phosphor powder of the present invention. Its emission spectrum see Figure 5 , it can be seen from the figure that the main emission peak wavelength of the phosphor is broadened, and the...

Embodiment 3

[0053] The chemical formula of the fluorescent powder product of this embodiment is Sr after analysis. 0.44 Ba 0.5 Si 2 o 2 N 2 :0.06Eu / Ba 0.94 Si 2 o 2 N 2 :0.06Eu. Its manufacturing method is to weigh SrCO respectively according to the stoichiometric ratio 3 (4N), BaCO 3 (4N), SiO 2 (4N), Si 3 N 4 (4N), Eu 2 o 3 (4N) and BaCO 3 (4N), SiO 2 (4N), Si 3 N 4 (4N), Eu 2 o 3 (4N); wherein, respectively add 3% by weight of NaF (AR) of the total amount of raw materials, put the above-mentioned raw materials into a molybdenum crucible after mixing and grinding evenly, and put them into a molybdenum crucible at 1550 ° C in NH 3 Insulated in the atmosphere for 4 hours, the resulting product is crushed, pickled to remove impurities, hydraulically classified, and dried, and the Ba 0.94 Si 2 o 2 N 2 :0.06Eu flame sprayed on Sr 0.44 Ba 0.5 Si 2 o 2 N 2 : 0.06Eu surface, namely the phosphor powder of the present invention. Its emission spectrum see Figure 6 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Half width | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com