Flexible pneumatic robot

A robotic and flexible technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of poor versatility and high cost of gripping equipment, and achieve the effects of convenient and quick replacement, large gripping force, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

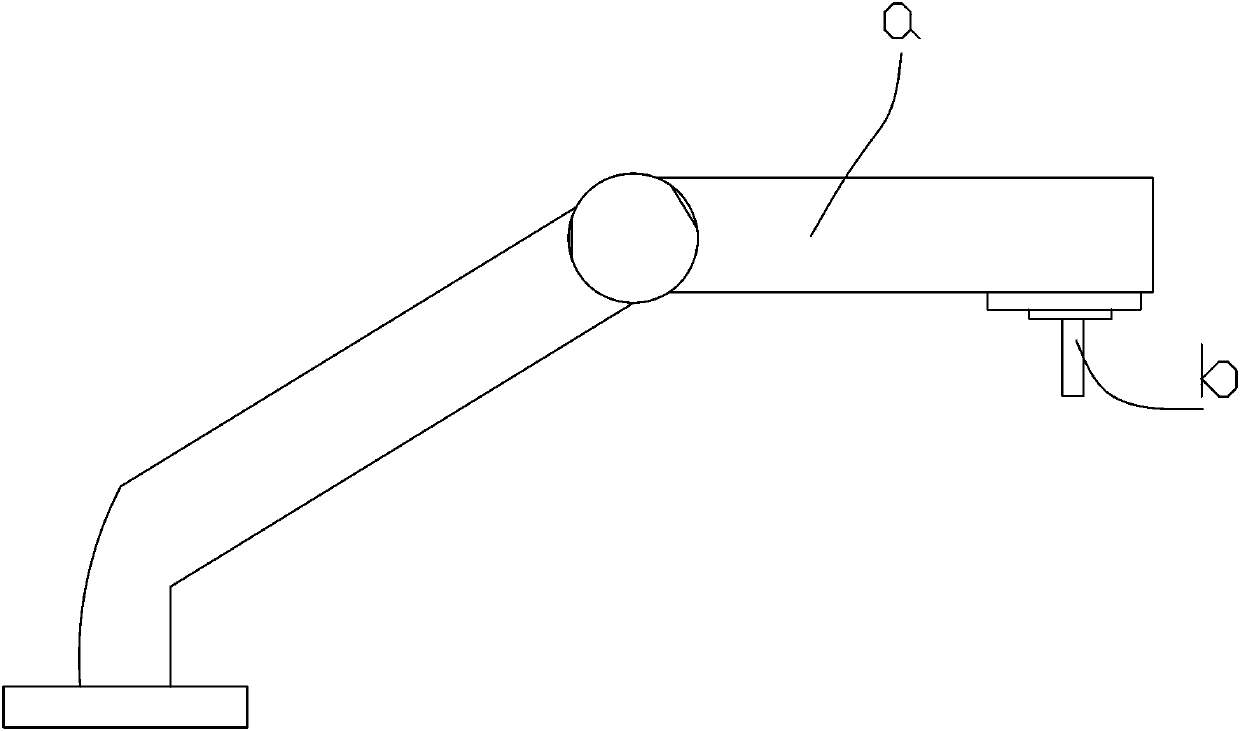

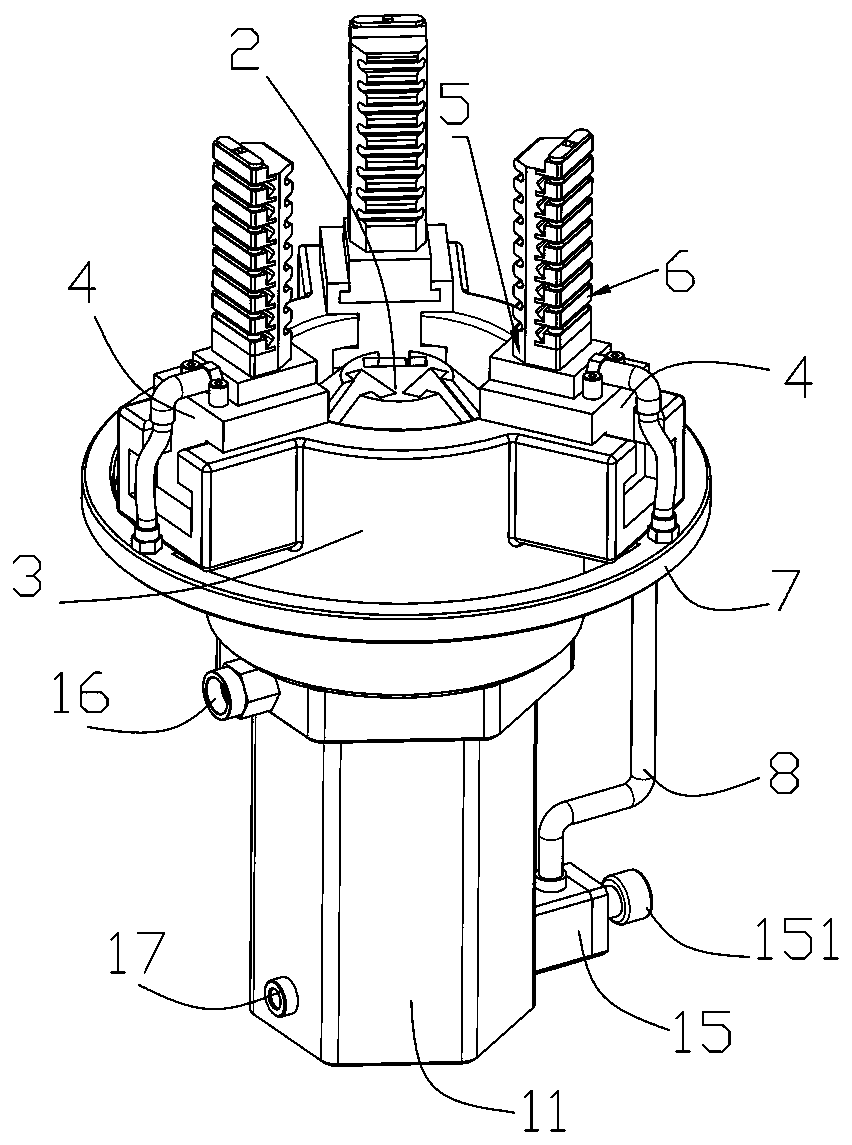

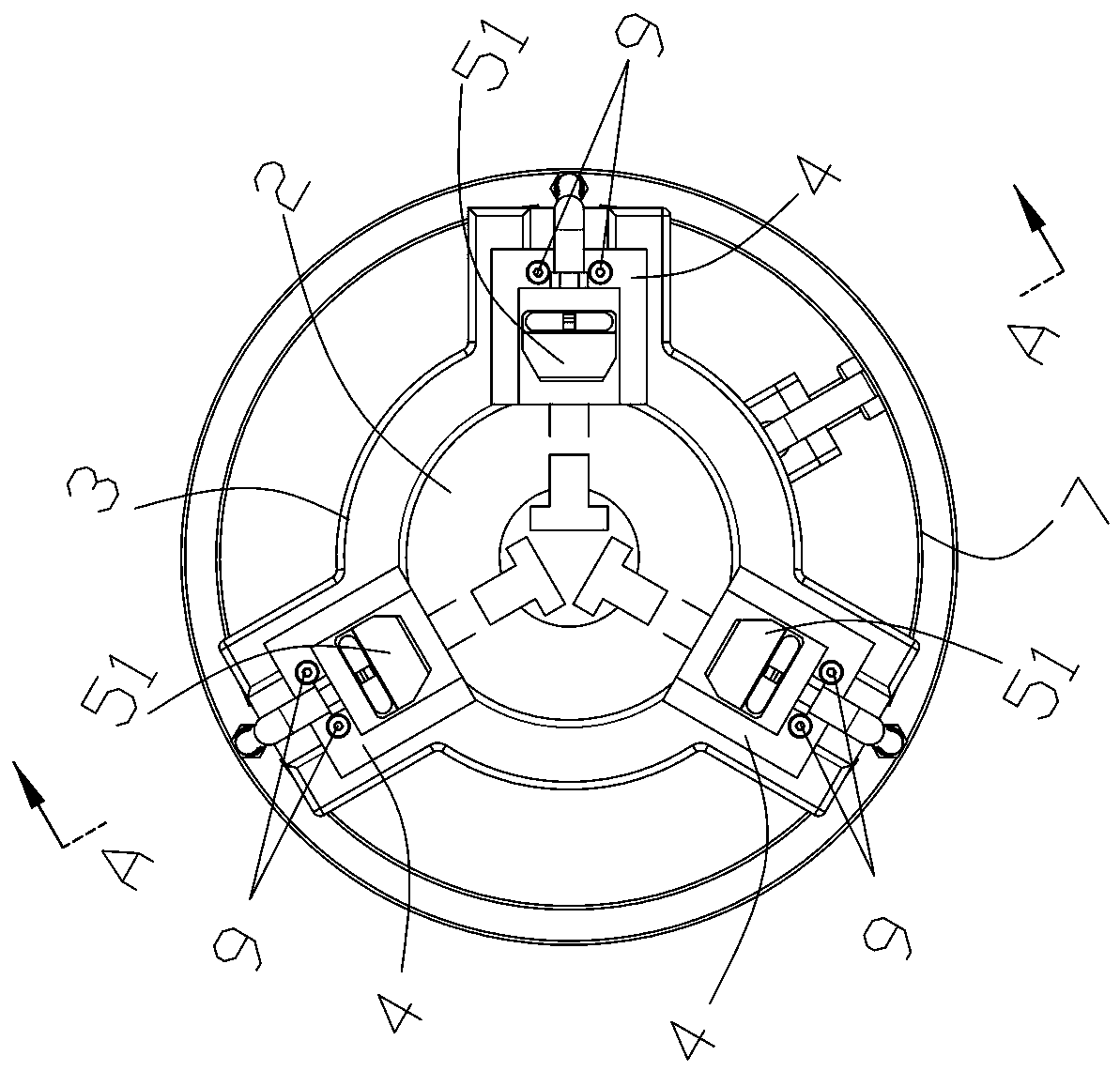

[0030] Such as Figure 1 to Figure 13 As shown, a flexible pneumatic robot described in this embodiment includes a power cylinder 1, a tapered slide table 2 and a guide tube seat 3; the power cylinder 1 includes a cylinder body 11, a piston rod 12, and a cylinder end cover 13 , return spring 14, overflow valve 15, air pipe joint 16 and intake check valve 17, described cylinder end cap 13 is fixed on one end of cylinder body 11, and a cylinder is formed between described cylinder end cap 13 and cylinder body 11 chamber, the piston rod 12 is located in the cylinder chamber, the piston rod 12 divides the cylinder chamber into an upper chamber and a lower chamber, one end of the piston rod 12 stretches out after passing through the cylinder end cover 13, the Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com