Operation method of a mixing feeding hopper

An operation method and hopper technology, applied in the operation field of mixed feeding hoppers, can solve problems such as prioritizing the use of returned materials, and achieve the effects of ensuring material level height, ensuring accuracy, and eliminating interference signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make it easy to understand the technical means, creative features, achieved goals and effects of the present invention, the following embodiments will describe the present invention in detail with reference to the accompanying drawings.

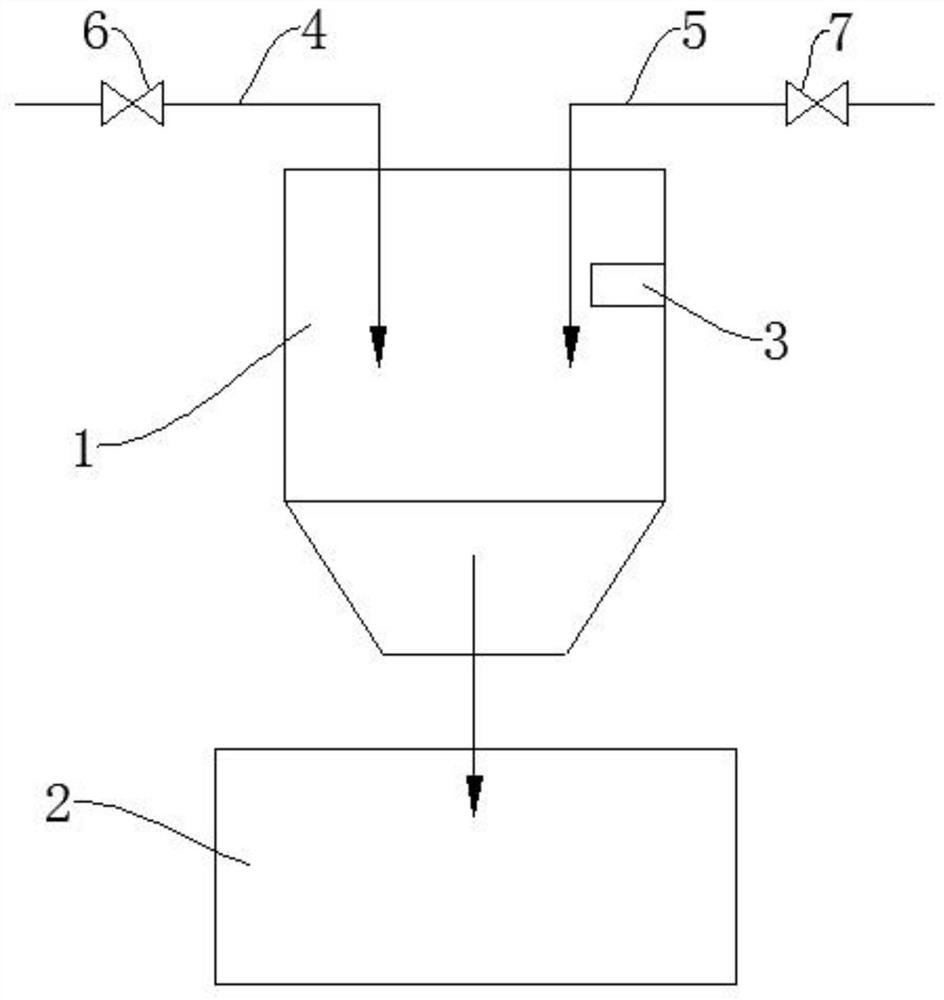

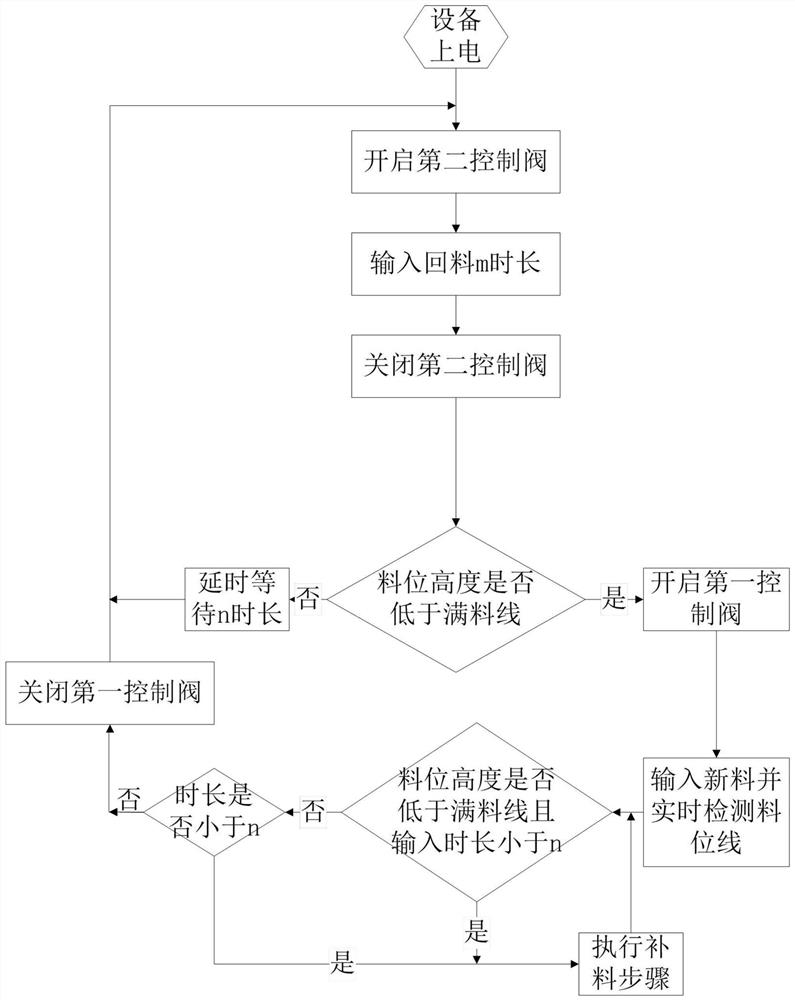

[0021] see figure 1 and figure 2 As shown in , in the operation method of the mixing feeding hopper provided in this embodiment, the mixing feeding hopper includes a hopper body 1, and at least one material level gauge 2 is installed on the inner wall of the hopper body 1, and the material level gauge 2 defines the interior of the hopper body 1 The upper end of the hopper body 1 has a new material inlet and a return material inlet, and a new material conveying line 4 is installed in the new material inlet, and a first control valve 6 is installed on the path of the new material conveying line 4. A return conveying line 5 is installed in the material inlet, and a second control valve 7 is installed on the path of the retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com