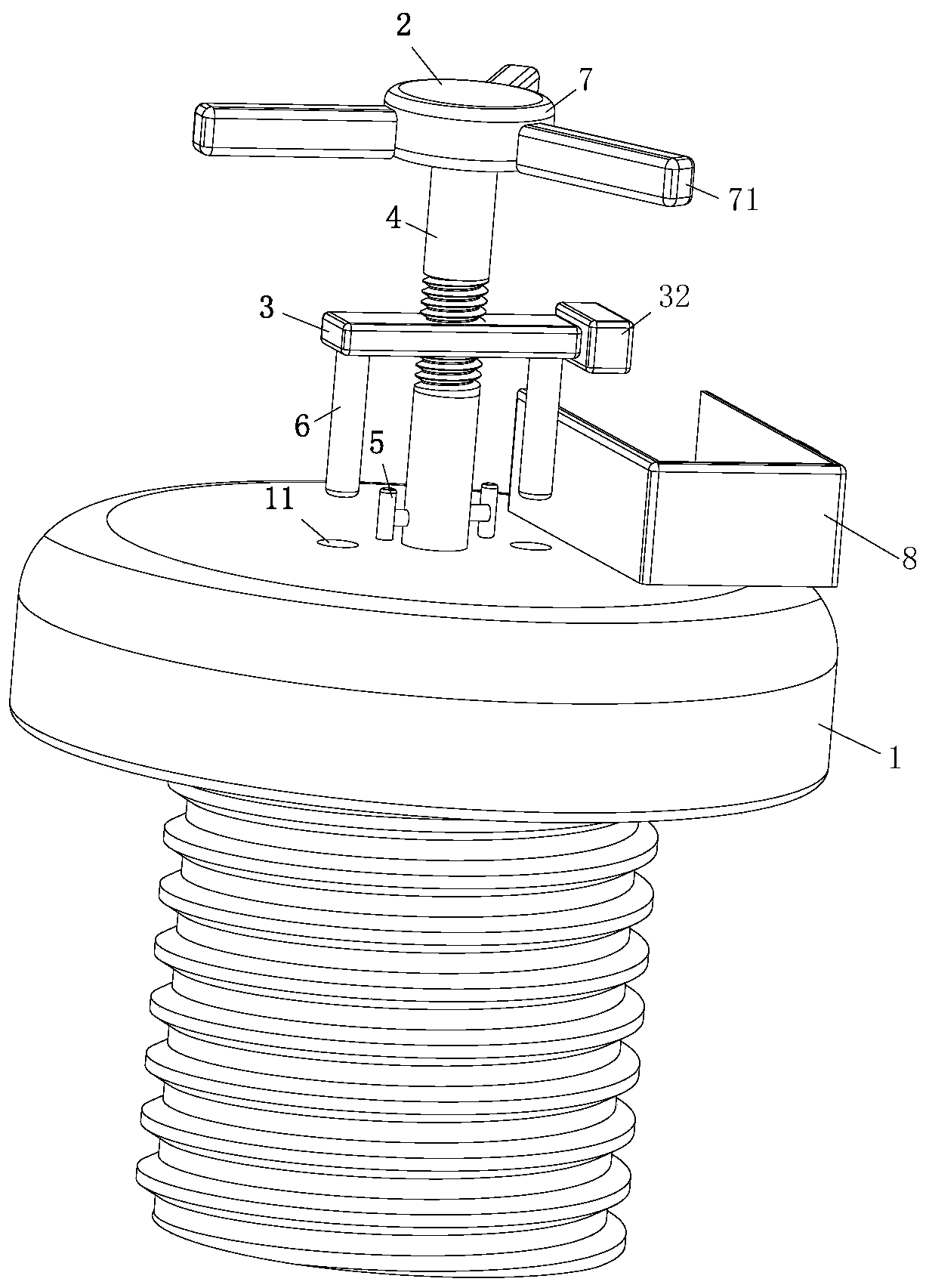

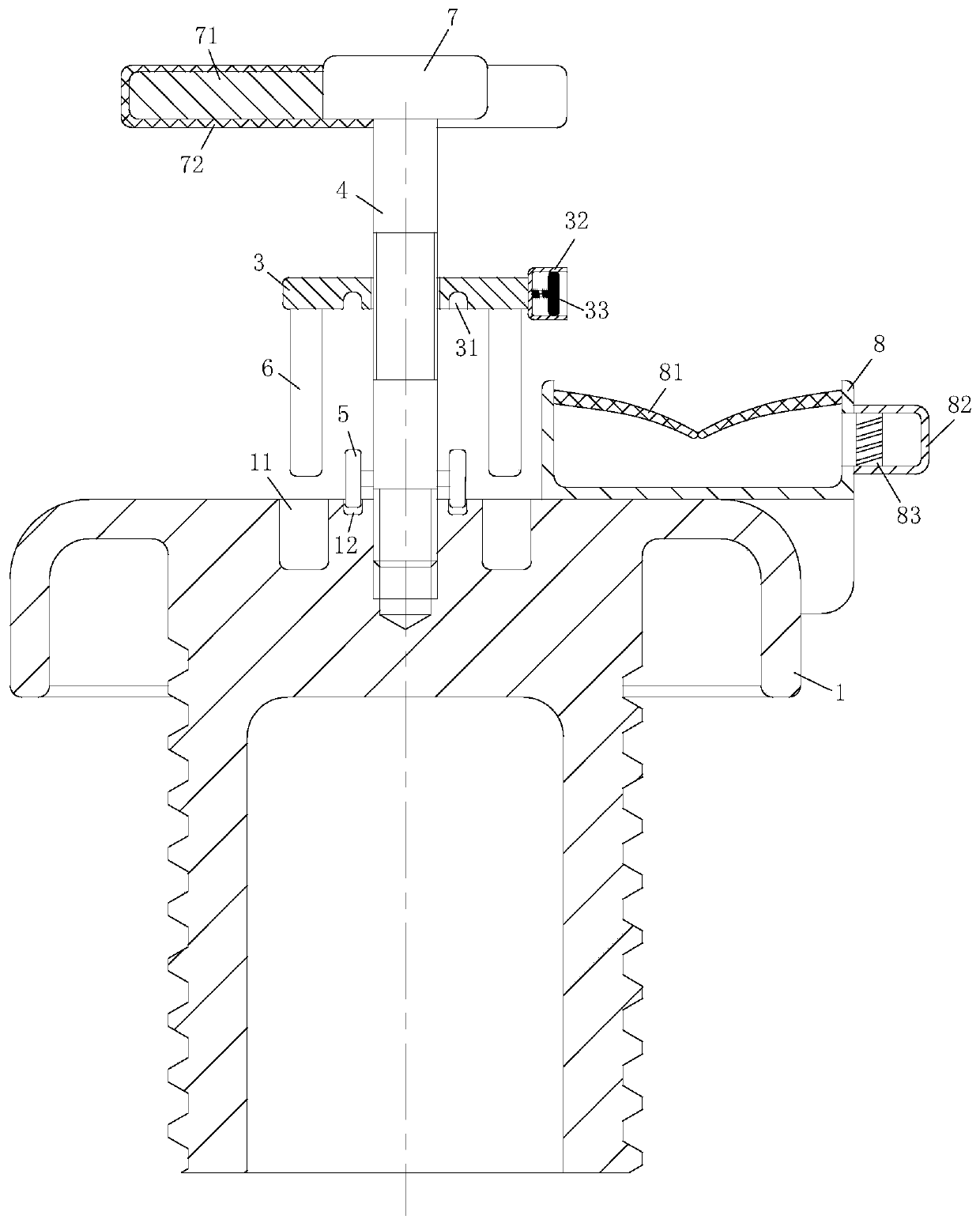

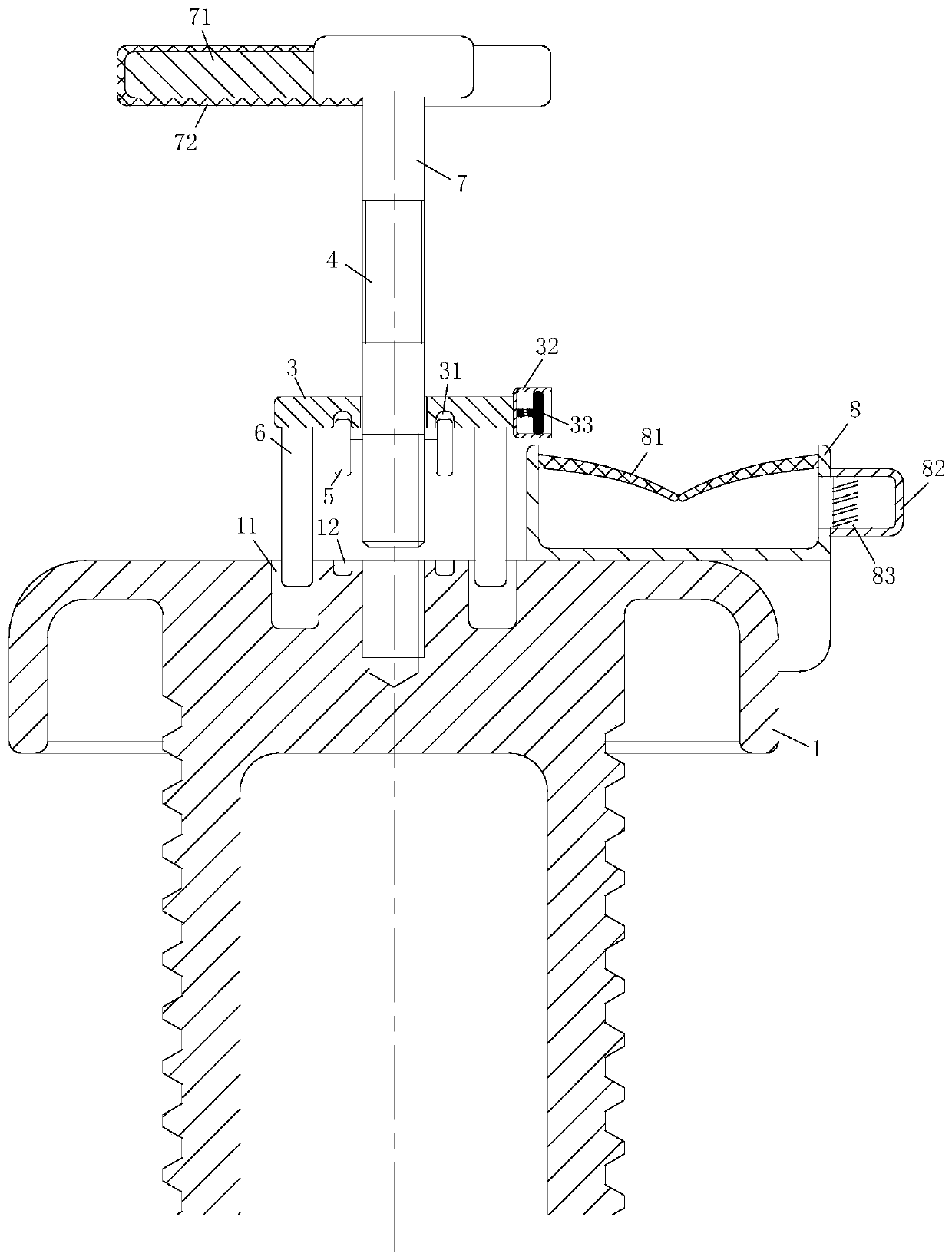

Tank cover of fuel tank

A fuel tank and tank cover technology, which is applied in the field of auto parts, can solve the problems of difficulty in removing the fuel tank cover, fuel tank oil leakage, fuel leakage, etc., to enhance the unscrewing effect, increase the effective area, and reduce the local damaged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] As an embodiment of the present invention, a storage box 8 is provided on the top of the housing 1, and arc-shaped elastic membranes 81 are symmetrically connected to the side walls of the storage box 8, and the ends of the elastic membranes 81 are in contact with each other. During work, after the support plate 3 and the rotating rod 4 complete the removal and installation of the case cover, the bottom of the support plate 3 and the rotating rod 4 is squeezed into the elastic membrane 81 in the storage box 8, and the symmetrically arranged The tops of the arc-shaped elastic membranes 81 are in contact with each other and compressed, so that the mutually extruded elastic membranes 81 protect the support plate 3 and the rotating rod 4 inside the storage box 8, and store the supporting plate 3 and the rotating rod 4 in the storage box. The function inside the box 8 effectively reduces the pollution and corrosion caused by the contact of the support plate 3 and the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com