A universal ball mesh belt and its production process

A universal ball, production process technology, applied in the directions of transportation, packaging, conveyors, etc., can solve the problems of difficult sorting and rotation of the same machine, difficult to meet the actual use requirements, etc., and achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

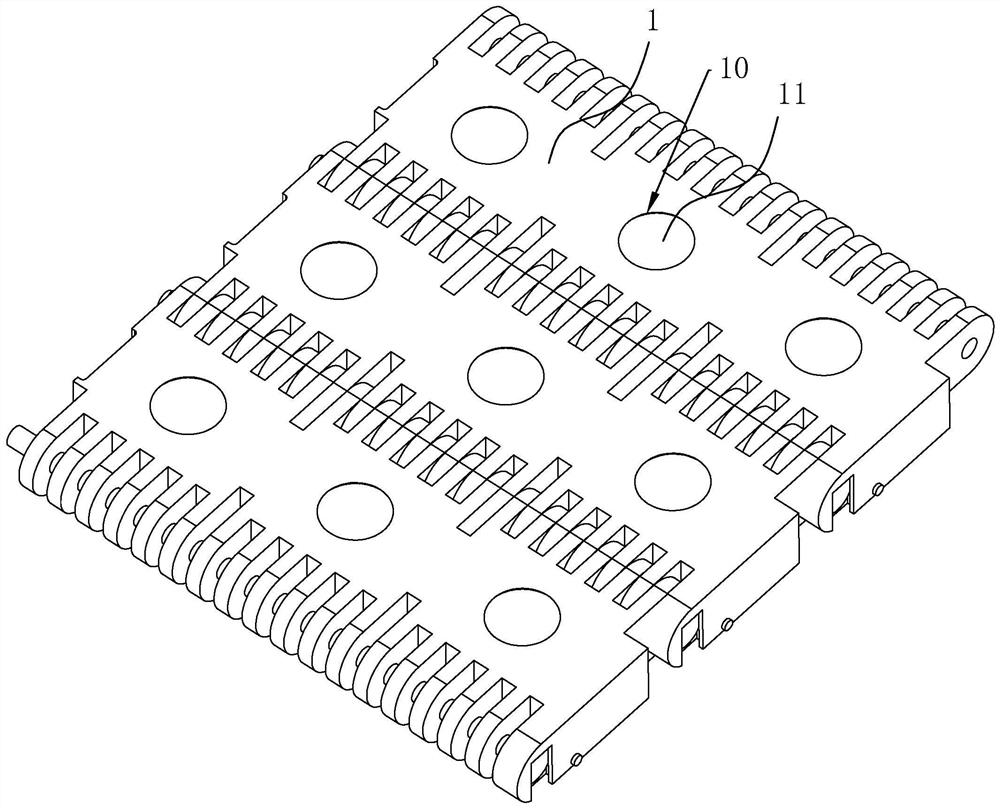

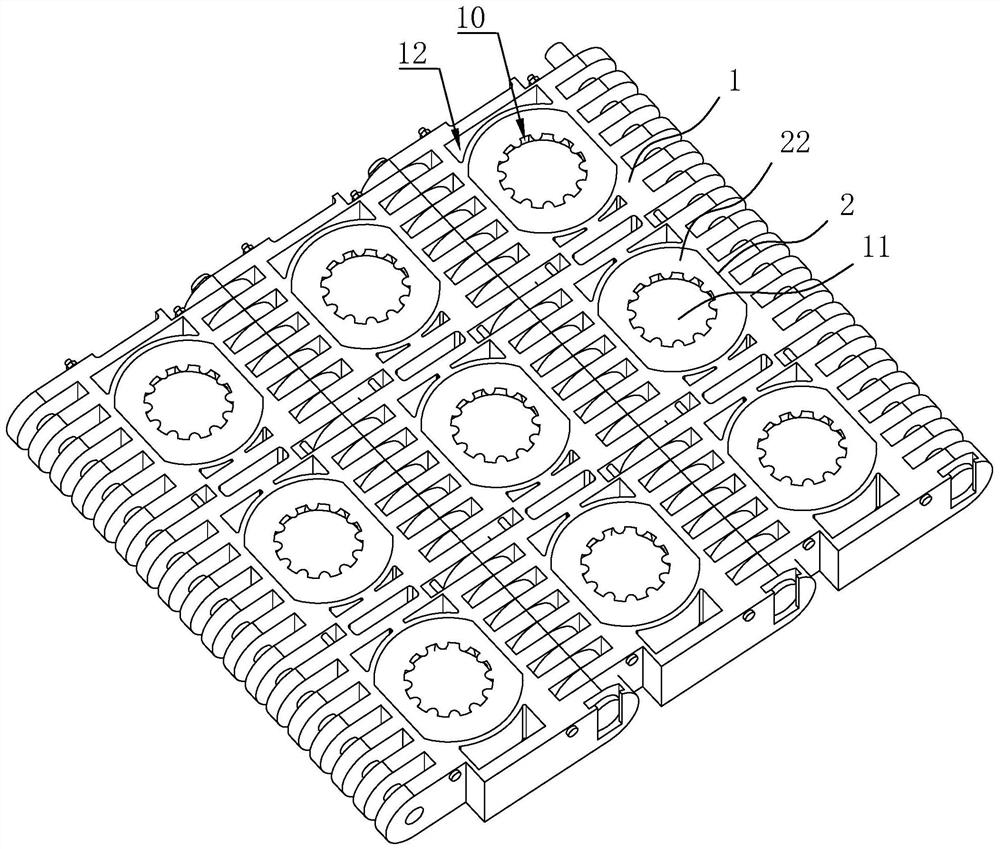

[0039] A universal ball mesh belt, refer to figure 1, which includes a number of module bodies 1 that are rotatably connected by pins. A plurality of accommodating cavities 10 are arranged in the plurality of module bodies 1 along the length direction thereof, and balls 11 are arranged in each of the plurality of accommodating cavities 10 .

[0040] refer to figure 1 and figure 2 , the plurality of accommodating cavities 10 are open at both ends, the two ends of the plurality of balls 11 respectively protrude from the openings at both ends of the corresponding accommodating cavities 10, and the inner diameters of the openings at both ends of the plurality of accommodating cavities 10 are smaller than the inner diameter of the middle The diameter of the several balls 11 is larger than the diameter of the inner edge of the openings at both ends of the corresponding accommodating cavity 10 , and the several balls 11 are clearance-fitted with the corresponding accommodating cav...

Embodiment 2

[0048] A production process based on a universal ball mesh belt, comprising the following steps:

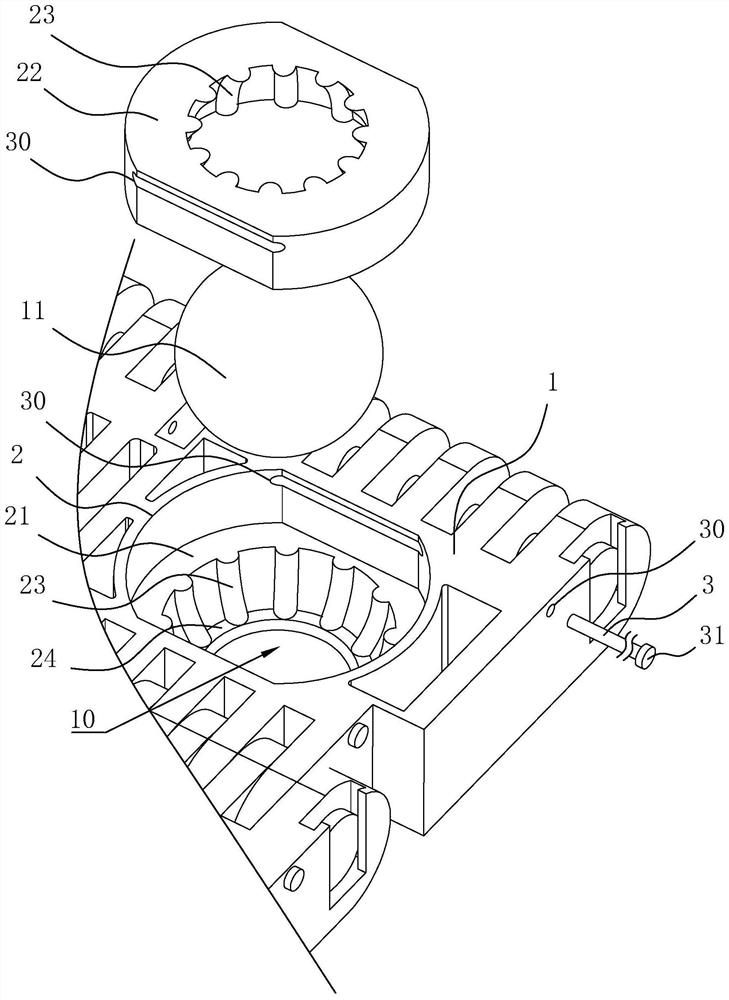

[0049] S1. The module body 1, the balls 11 and the lower limit convex ring 22 of corresponding specifications are produced by an injection mold.

[0050] S2. First place the balls 11 in the accommodating holes 2 of the module body, and then insert the lower limit convex ring 22 into the corresponding accommodating holes 2 to cover the balls 11, after which the balls 11 can be placed in the upper limit convex ring 21 and the accommodating cavity 10 enclosed by the lower limit convex ring 22 can rotate freely.

[0051] S3. The connection between the lower limit convex ring 22 and the accommodating hole 2 is welded by the ultrasonic plastic welding machine, so that the lower limit convex ring 22 is firmly connected with the accommodating hole 2, and it is naturally cooled, and then several module bodies 1 are passed through the pin shaft. connected to complete the production of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com