Compact and vertical adjusting unit for headlight mounted in vehicle

A technology for adjusting units, headlights, applied in the direction of headlights, components of lighting devices, lighting and heating equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

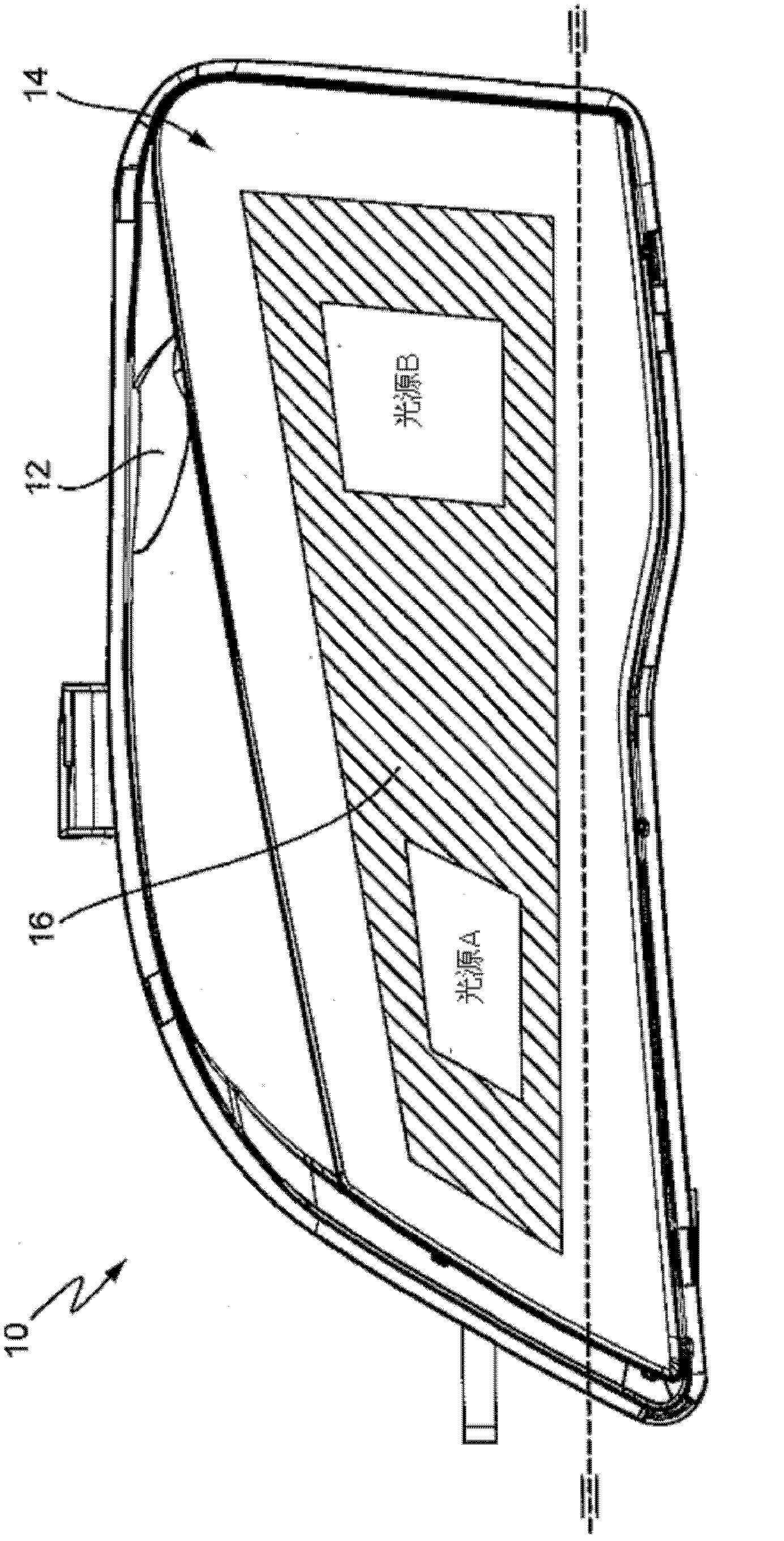

[0026] exist figure 1 A headlight 10 is shown in , which contains two light sources A and B, a headlight housing 12 and a control unit 14 . The two light sources A and B are arranged here on the carrier element 16 . Light source A refers to basic light. The light source B is designed as a so-called point light. Light source A thus provides widely dispersed elementary light below the horizontal light / dark boundary, while light source B provides the light path (spot functionality) of the light. The two light sources A and B, from which the light distribution of the headlight 10 is formed, can be positioned relative to each other by means of an adjustment unit 14 here.

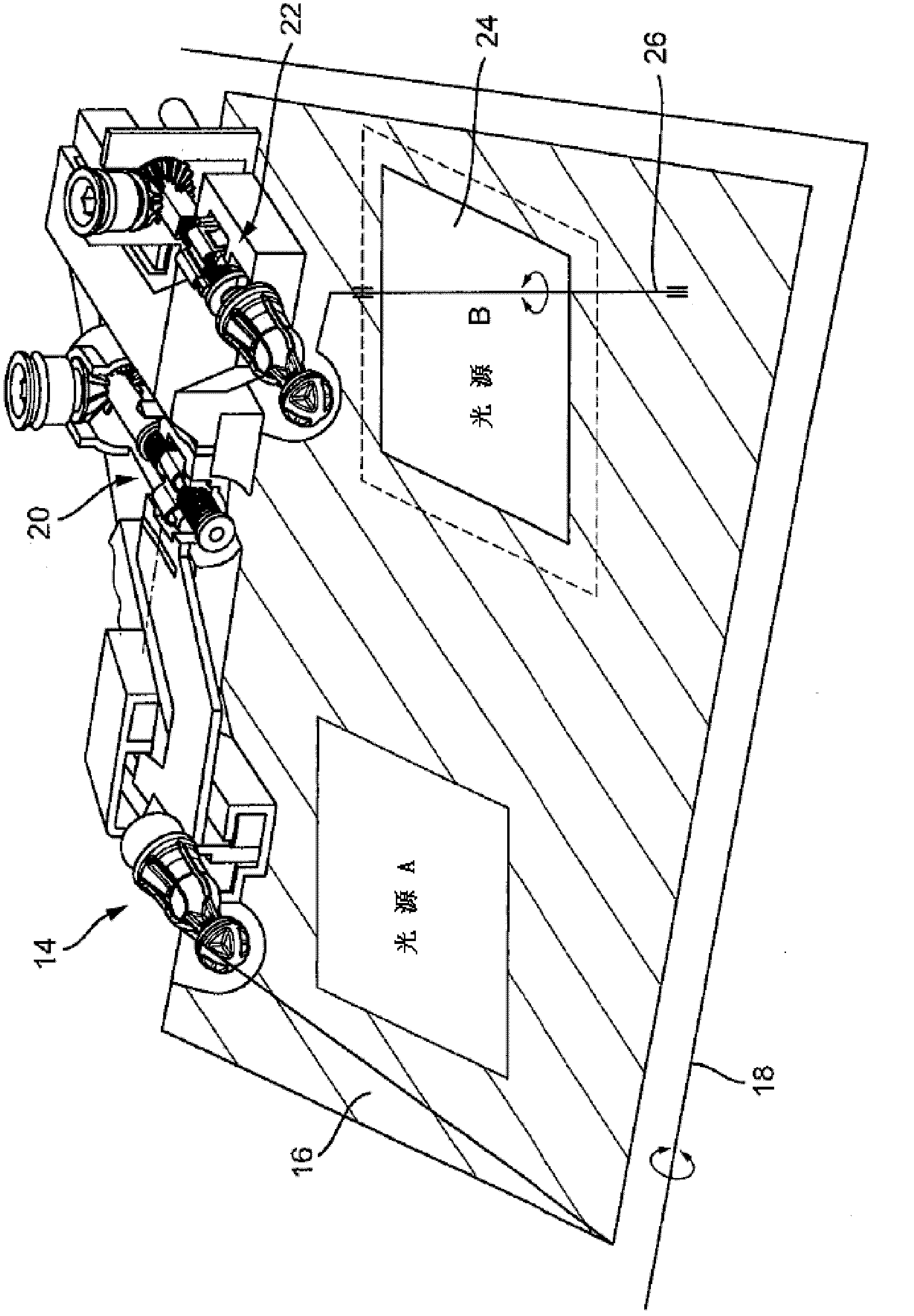

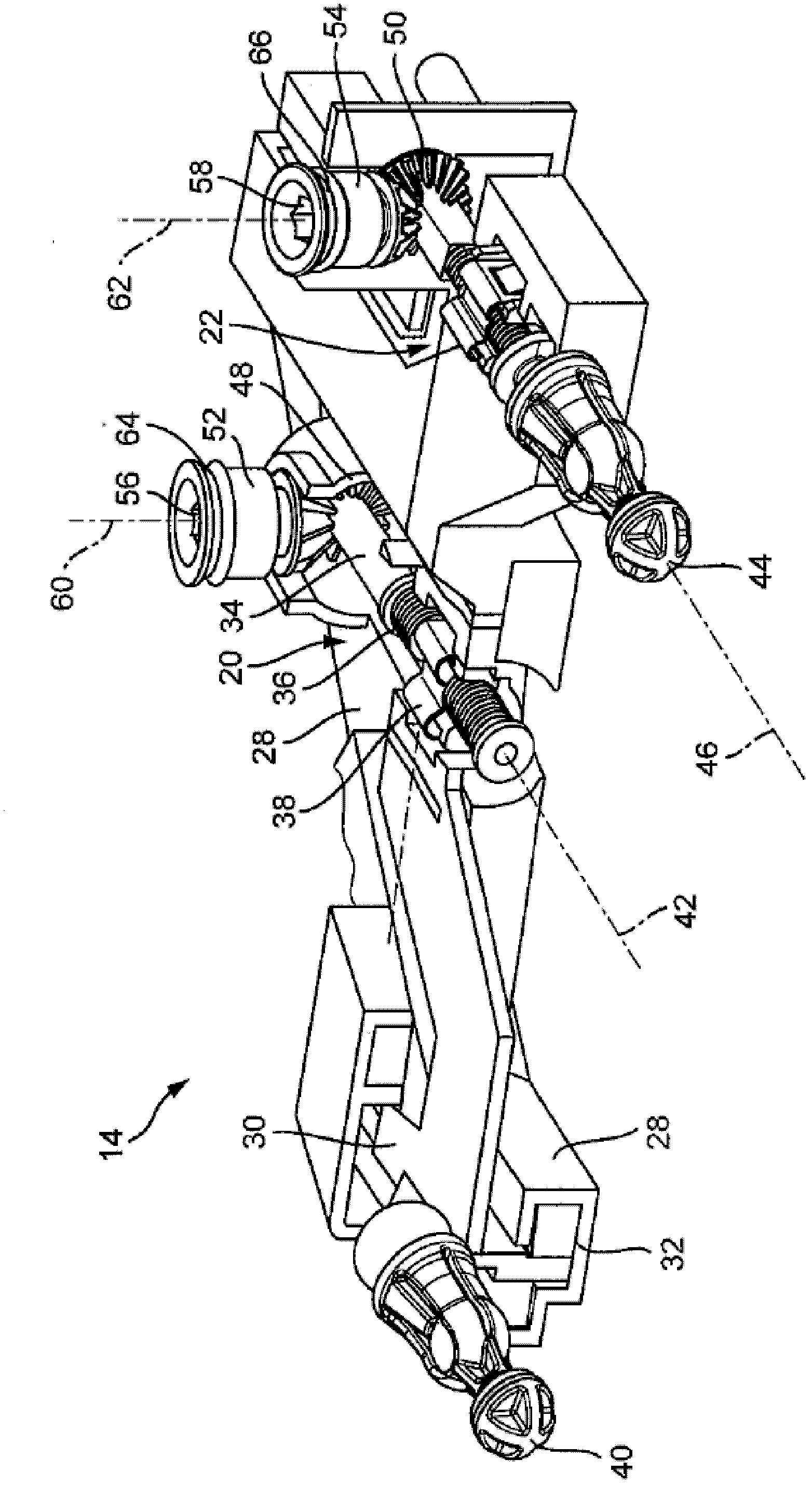

[0027] exist figure 2 The adjusting unit 14 can clearly be seen in FIG. 2 , which has a carrier element 16 carrying the two light sources A and B. In FIG. In this case, the adjustment unit 14 is arranged behind the carrier element 16 in the headlight and thus in the figure 1cannot be seen in . The carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com