External wall construction supporting device and using method thereof

An auxiliary device and exterior wall technology, applied in the direction of lifting devices, etc., can solve the problems of increased risk and work efficiency, low degree of automation and intelligence, unstable working position, etc., so as to facilitate fine construction, no cumulative error, and structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

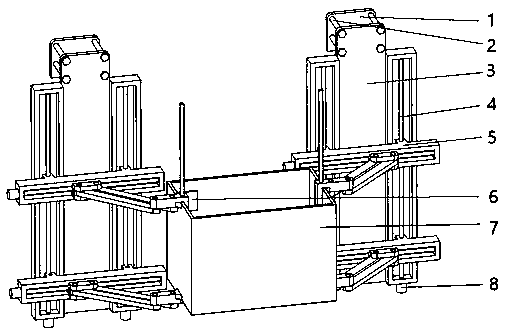

[0023] like figure 1 The shown auxiliary device for external wall construction includes a work safety box 7 and two sets of vertically arranged clamping plates 1 and vertical support plates 3 symmetrically arranged on both sides of the work safety box 7 . The working safety box 7 is a box structure with an open top. The clamping plate 1 is fixedly connected to both sides of the wall by bolts 2 and a vertical support plate 3, wherein the vertical support plate 3 is located outside the wall. The vertical support plate 3 is provided with two vertical groove bodies, and the vertical groove body is provided with a movable vertical lead screw 4, and the vertical lead screw 4 is driven to rotate by a driving motor.

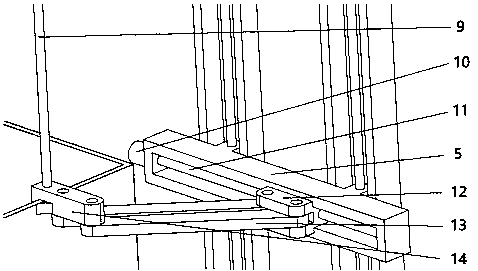

[0024] like figure 2 As shown, the vertical screw 4 is connected with two moving bases 5 through threads, the moving base 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com