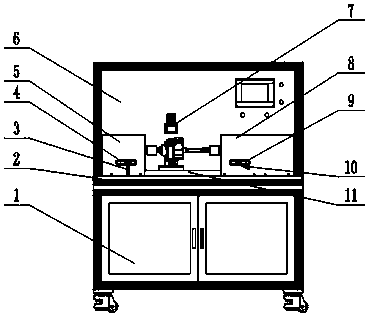

Speed reducer assembly no-load moment testboard

A technology of reducer and no-load force, applied in the field of no-load torque test equipment of reducer assembly, can solve the problem that the no-load torque of reducer assembly is inconvenient to fix, affects the accuracy of fixation, angle encoder and motor cannot move, etc. problems, to facilitate the no-load torque test, improve the convenience of fixing, and improve the effect of locking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

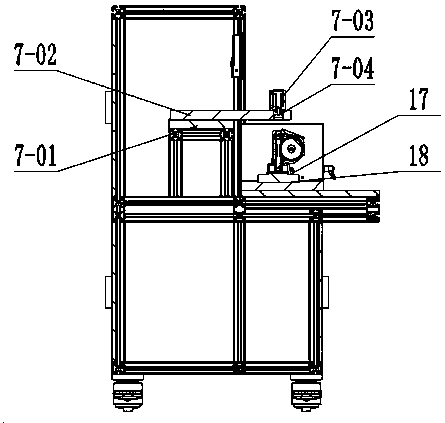

[0028] Specific implementation method: first, the reducer assembly 16 is fixed on the upper end surface of the positioning member 18 through the fixed pin 17, and the lower pressure cylinder 704 is pressed against the upper end surface of the reducer assembly 16 by the lower pressure cylinder 703, because the support plate 701 and The cylinder mounting plate 702 makes the support of the downward pressure cylinder 703 more stable.

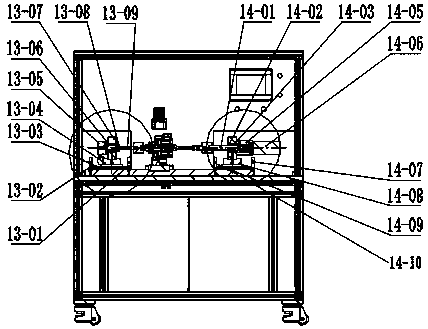

[0029] The reducer assembly 16 is connected with the left transfer shaft 1309 through the left coupling 12, because the left bracket 1307 and the lock nut 1308 are installed, the left transfer shaft 1309 has better support stability, because the first The bearing 1306 makes the left transfer shaft 1309 more stable when rotating. At this time, the operator adjusts the front and rear positions of the transfer board 1304 by twisting the wrench 3 with his left hand. Because the first line rail 1303 is installed on the lower end of the transfer board 1304...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com