Fixing mechanism for production of high-sealing-performance lock catch waveform wound reinforced pipe joints

A technology of winding reinforced tube and fixing mechanism, which is applied in the direction of grinding frame, grinding machine parts, grinding/polishing equipment, etc., and can solve the problems of inconvenient processing, single fixing method, manual adjustment of direction and fixed position, etc. , to achieve the effect of improving convenience and efficiency, improving flexibility and applicability, and improving the convenience of fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments.

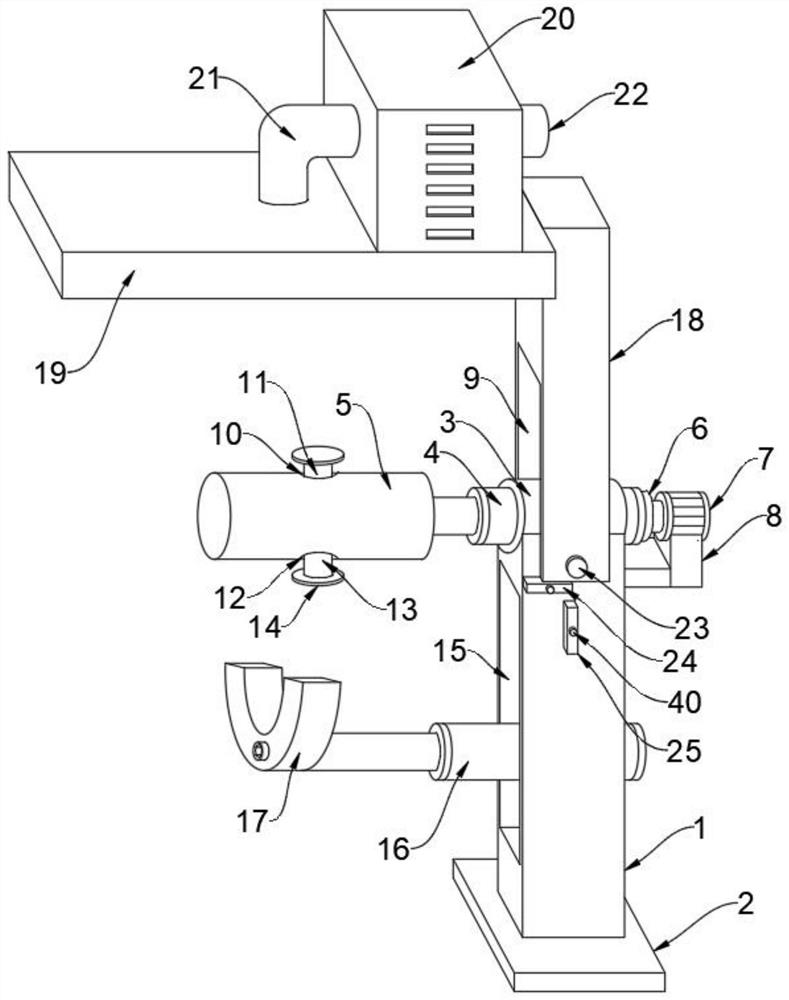

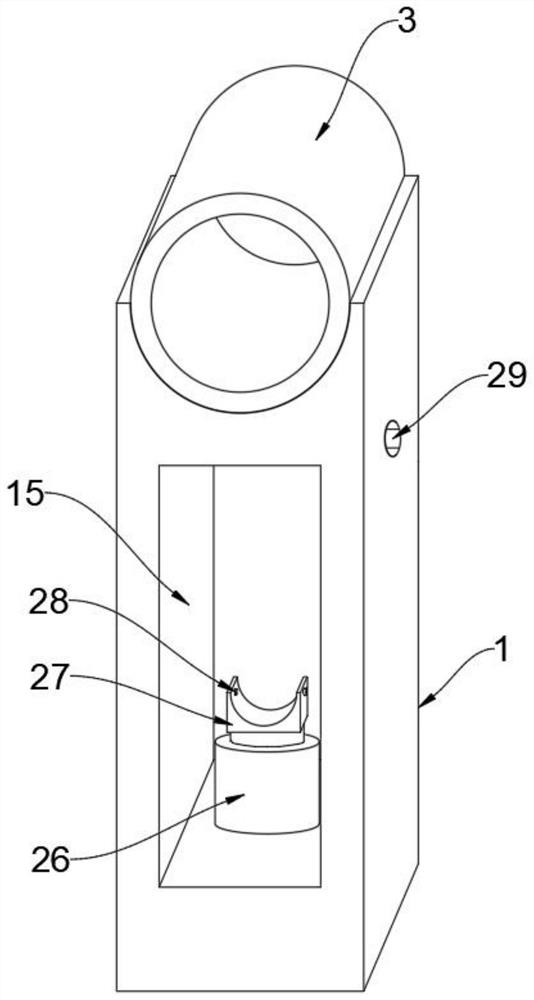

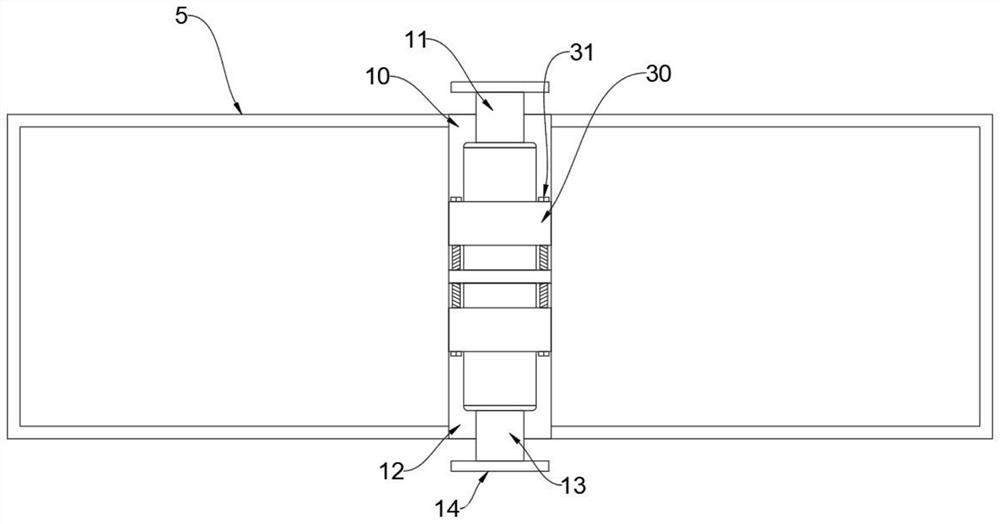

[0027] See Figure 1-5 One embodiment of the present invention: a high-sealing lock waveform wrap-enhanced pipe joint production fixing mechanism, including support column 1, and the upper end of the support column 1 is provided with a rolling bearing 3, and the internal setting of the rolling bearing 3 is provided with shrink electricity. The pusher assembly 4, one end of the shrink electric push rod assembly 4 is provided with a central post 5, and the central column 5 is welded to the shrink electric push rod assembly 4, and the other end of the shrinking electric push rod assembly 4 is provided with a connection pad 6, the connection pad. 6 On the side of the 6, the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com