Submarine air foam fire extinguishing system

An air foam and fire extinguishing system technology, which is applied in the field of air foam fire extinguishing systems for boats, can solve problems such as easy fracture, low shape retention effect, and low foam stability, so as to avoid fouling, excellent fire extinguishing effect, and facilitate operation and maintenance. The effect of overhaul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

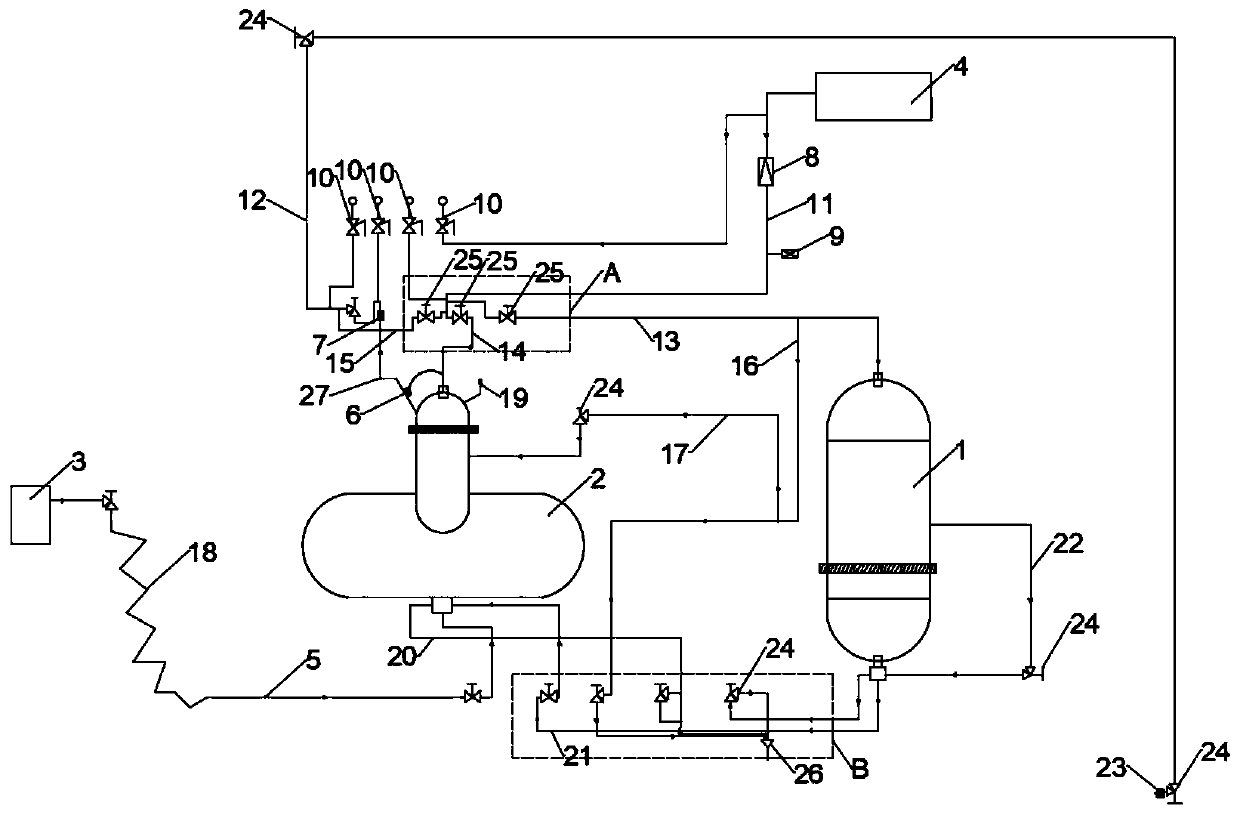

[0028] like figure 1 Shown, a kind of boat air foam fire extinguishing system comprises air foam meter 1, air foam storage tank 2, discharge funnel 26 and water supply equipment 3 and high-pressure air supply equipment 4, and described air foam meter 1 and described air The foam storage tanks 2 are connected by a foaming agent pipeline 21, and a fresh water pipeline 5 is provided between the water supply equipment 3 and the air foam storage tank 2;

[0029] The high-pressure air supply equipment 4 is connected to the air foam storage tank 2 by setting a high-pressure air pipeline 11, and the high-pressure air pipeline 11 is sequentially provided with a pressure gauge valve 10, a pressure reducing valve 8, and a safety alarm valve 9 along the air supply direction;

[0030] The air foam storage tank 2 is provided with an air foam pipeline 27, the air foam pipeline 27 is connected with the main pipe 12, and the connection is provided with a right-angle stop check valve 24; There...

Embodiment 2

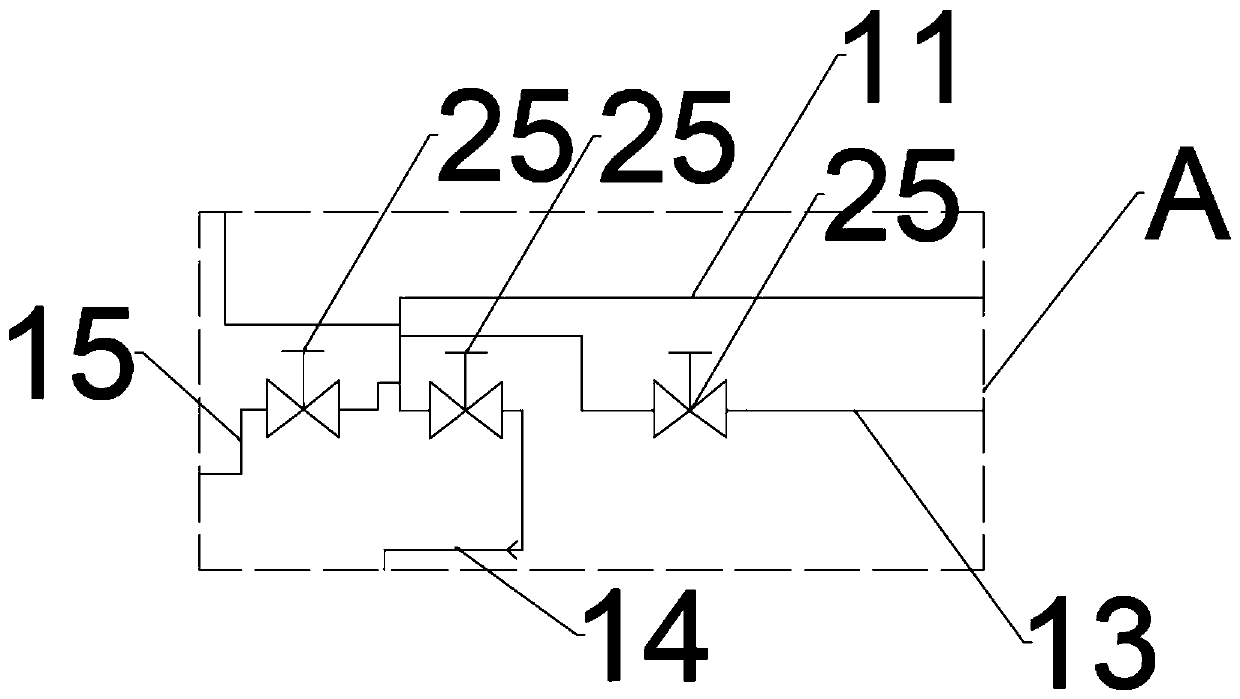

[0033] This embodiment is a further optimization made on the basis of Embodiment 1. Specifically, the high-pressure air pipeline 11 located behind the safety alarm valve 9 along the air supply direction is provided with a first branch vent pipe 13, a second branch vent pipe The air pipe 14 , the third branch air pipe 15 , the first branch air pipe 13 is connected to the feeding port of the air foam meter 1 .

Embodiment 3

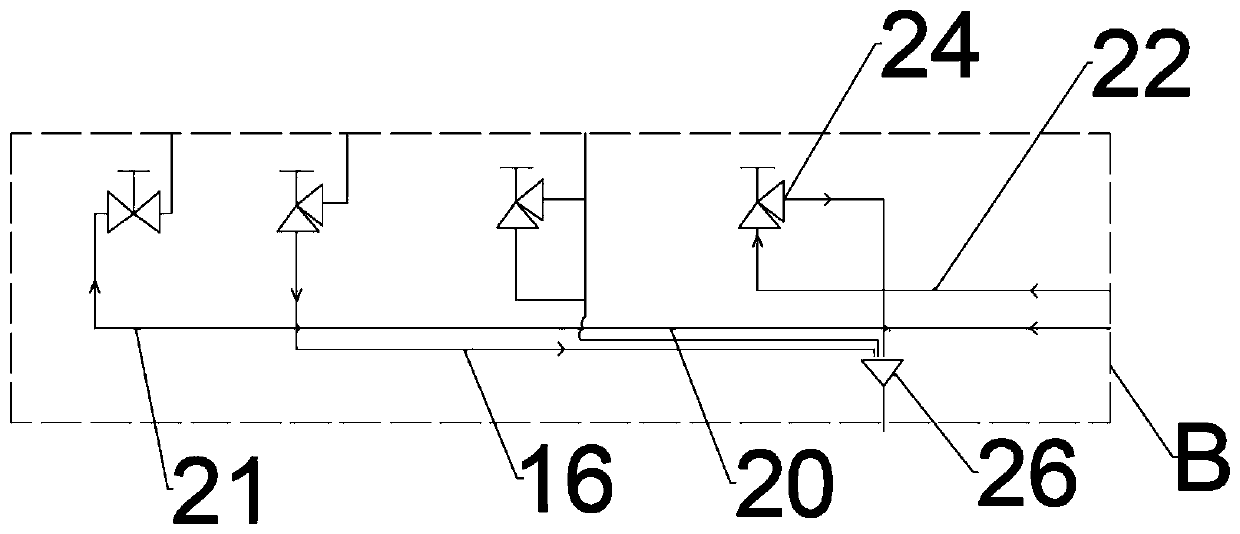

[0035] This embodiment is a further optimization made on the basis of Embodiment 2. Specifically, the air foam meter 1 is also provided with an air outlet pipeline 22, and the air outlet pipeline 22 is connected with the discharge funnel 26. On the air outlet pipeline 22 A right-angle cut-off check valve 24 is provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com