Three-freedom-degree pneumatic horizontal moving parallel mechanism

A degree of freedom and parallel technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of expensive parallel structure and achieve low production costs, easy control, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with accompanying drawing.

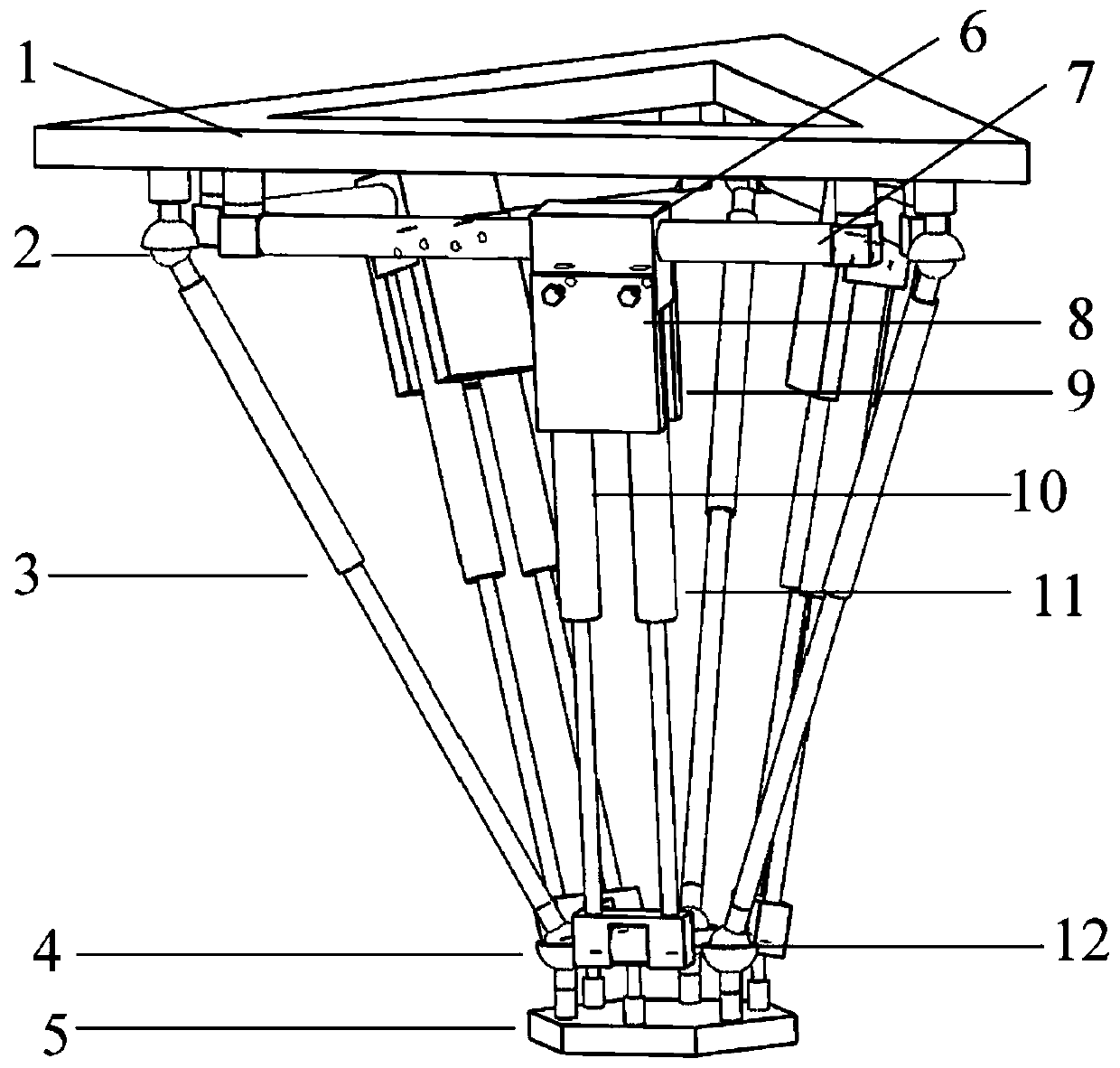

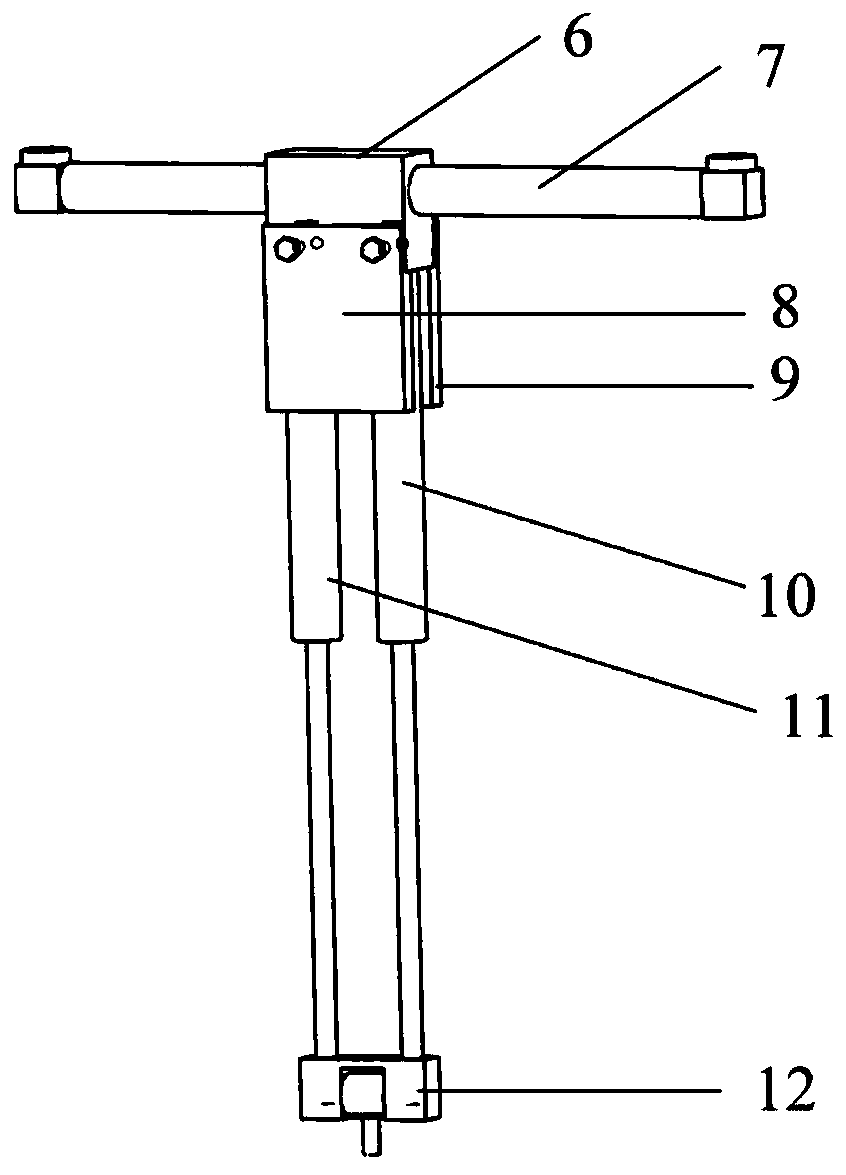

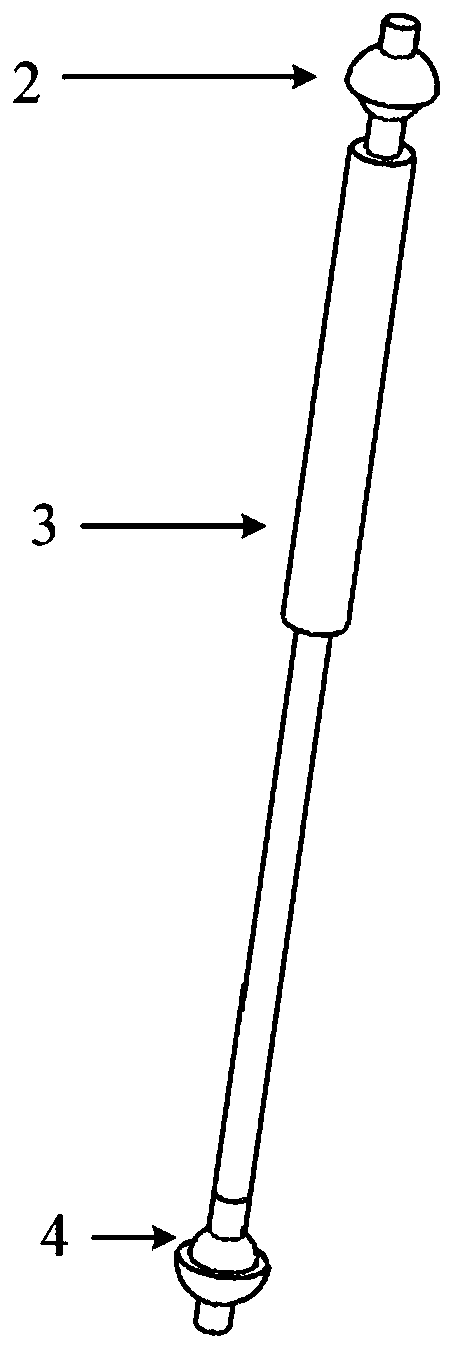

[0027] Such as figure 1 , 2 , 3, a three-degree-of-freedom pneumatic translation parallel mechanism disclosed in this embodiment includes a fixed platform 1, an upper spherical hinge 2, a drive cylinder 3, a lower spherical hinge 4, a movable platform 5, a cylindrical pair 6, a circular slide Rail 7, front baffle 8, rear baffle 9, left moving pair 10, right moving pair 11, rotating pair 12. The upper ball joint 2, the drive cylinder 3 and the lower ball joint 4 form a drive branch chain. The upper ball joint 2 of each driving branch chain is connected with the fixed platform 1, and the lower ball joint 4 is connected with the movable platform 5. The centers of the upper ball joints in the three driving branch chains are located on the same plane, and this plane is parallel to the plane where the fixed platform 1 is located; the circle centers of the lower ball joints i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com