Ball type corner lifting device

A lifting device and ball-type technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as unsatisfactory corners and cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

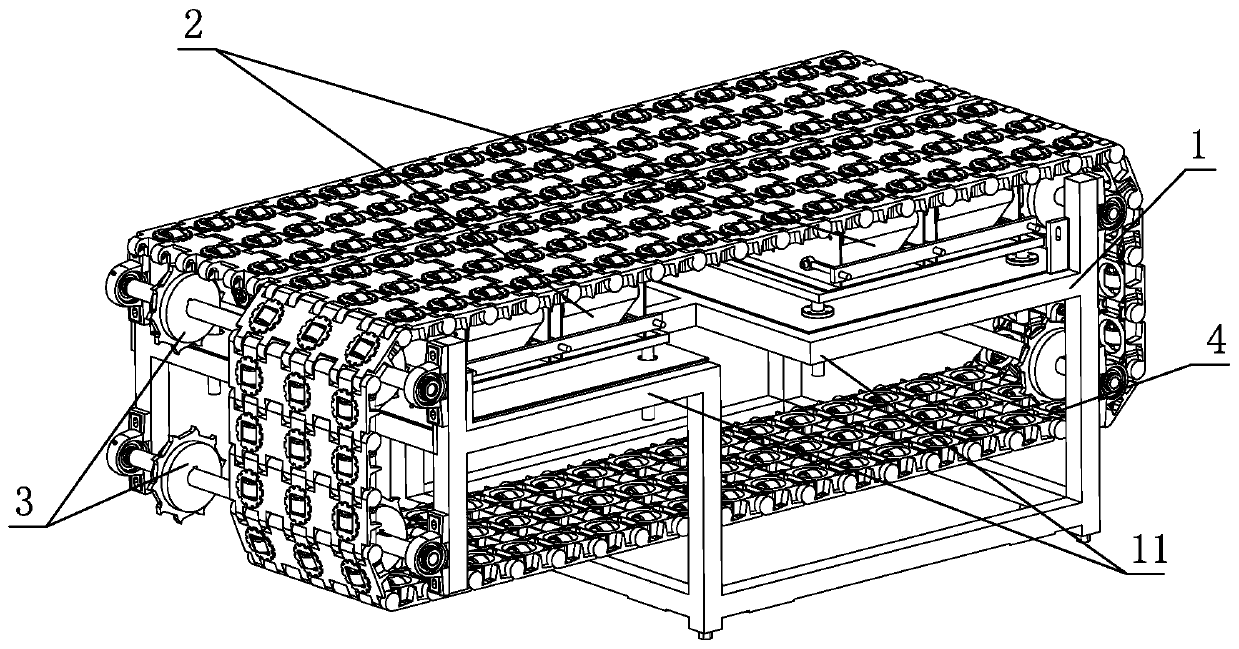

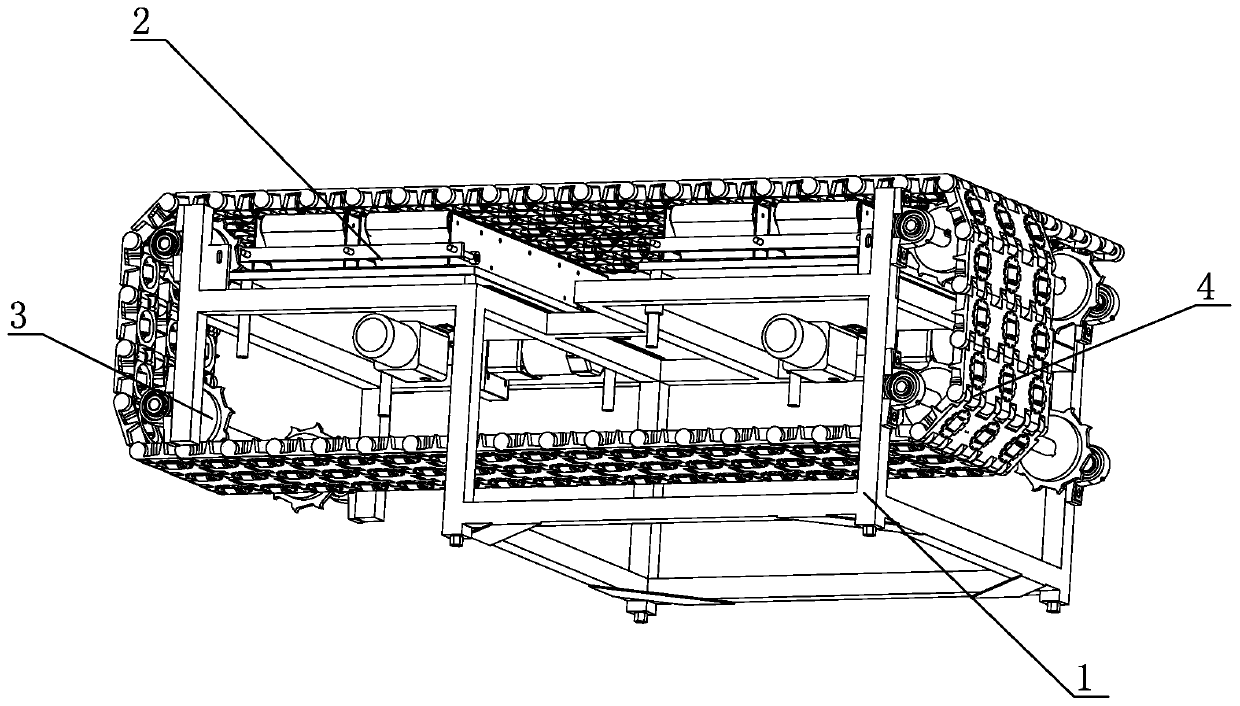

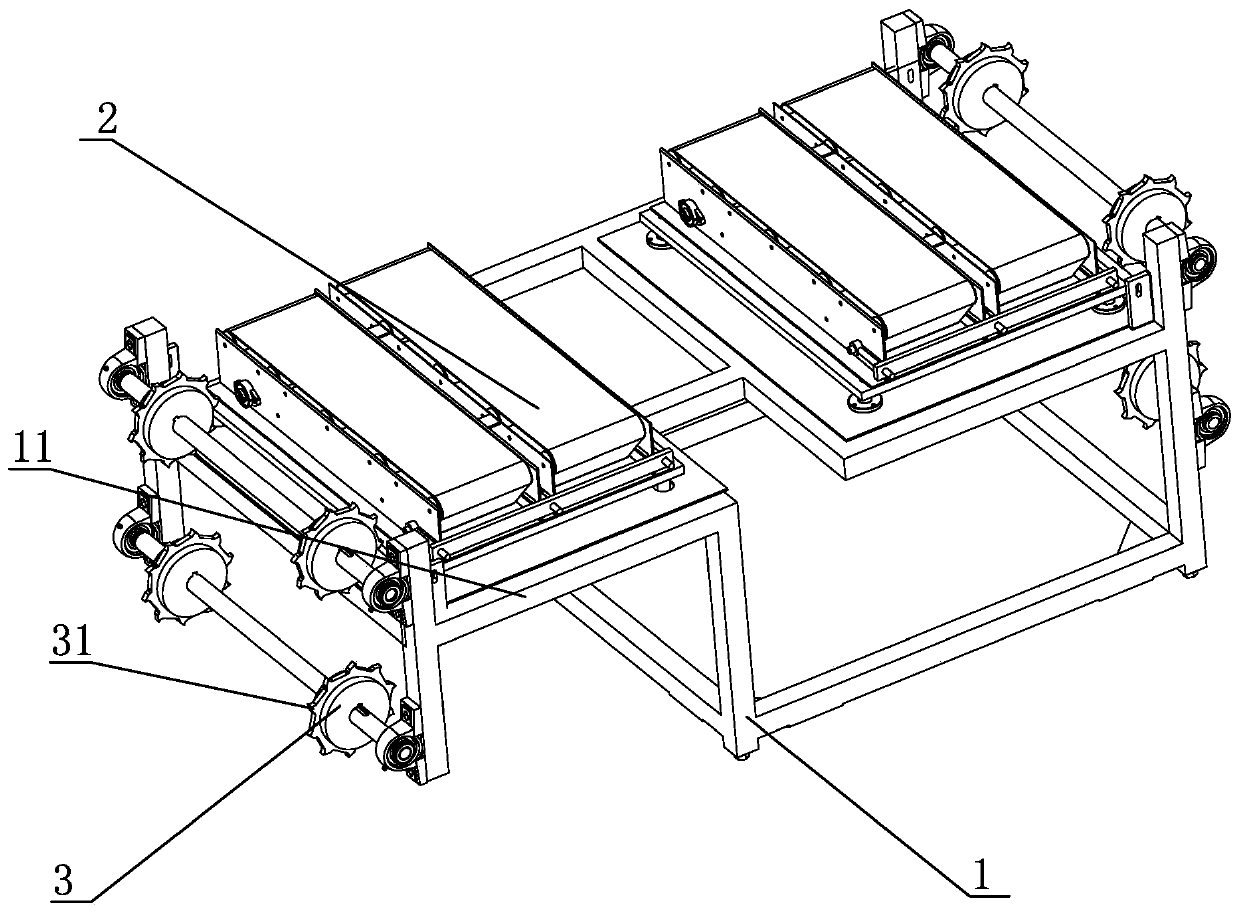

[0020] Such as Figure 1-8 As shown, the specific embodiment of the present invention adopts a ball type corner lifting device, which mainly includes an installation platform 1, a conveying line 4, a lifting device 2 and a transmission gear 3, and the transmission gear 3 is distributed on both sides of the installation platform 1, and the transmission line 4 is distributed on the installation platform 1 in a ring shape, and the transmission gear 3 distributed on both sides of the installation platform 1 is located inside the conveyor line 4. The conveyor line 4 is spliced by several ball-type mesh belts 5, and the ball-type mesh belt 5 It includes a matching groove 57 distributed on the back of the ball-type mesh belt 5 and a ball 51 on the upper limit of the ball-type mesh belt 5. The matching groove 57 is adapted to the gear teeth 31 of the transmission gear 3, and through the matching groove 57 and the gear teeth The meshing of 31 forms the movement of the conveying line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com