An automatic rotating anti-clogging bottom grid fence

An automatic rotation and anti-clogging technology, which is applied in the field of bottom grid fence to prevent the bottom grid fence from being blocked, can solve the problems of affecting water intake effect and bottom grid fence blockage, and achieves the effect of avoiding blockage and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

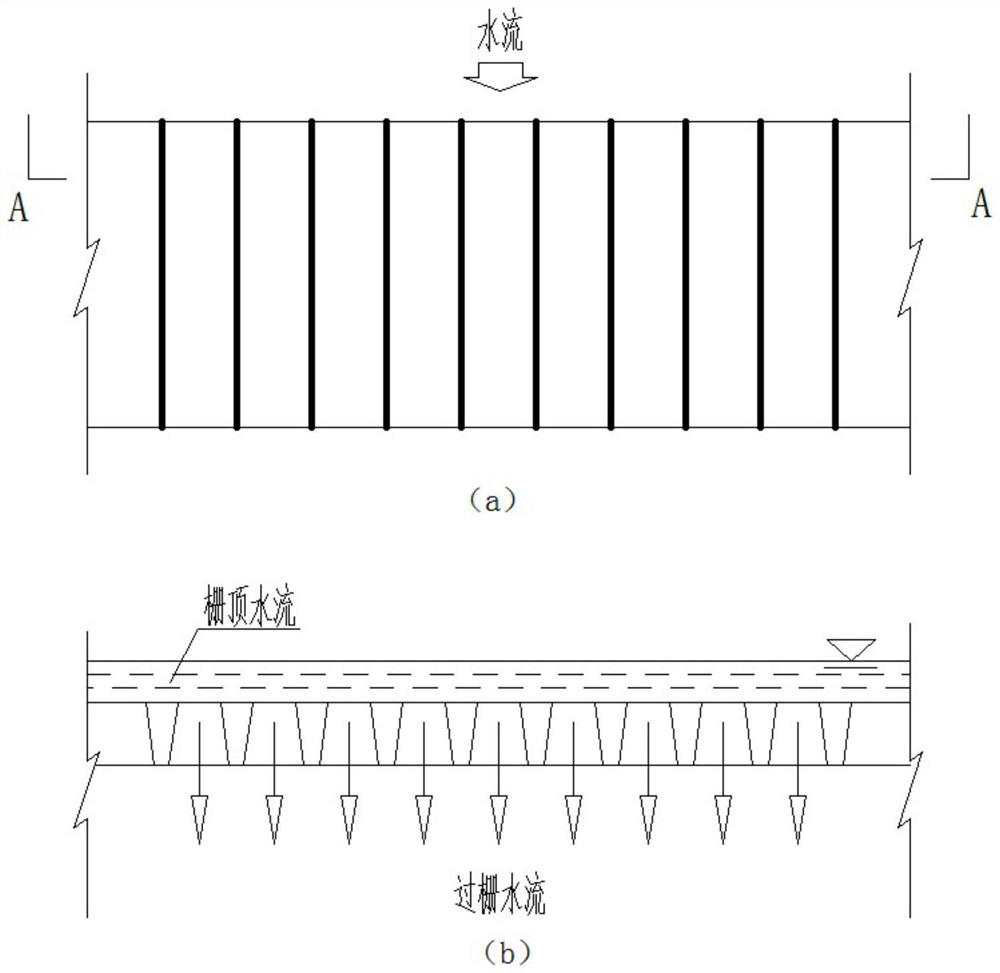

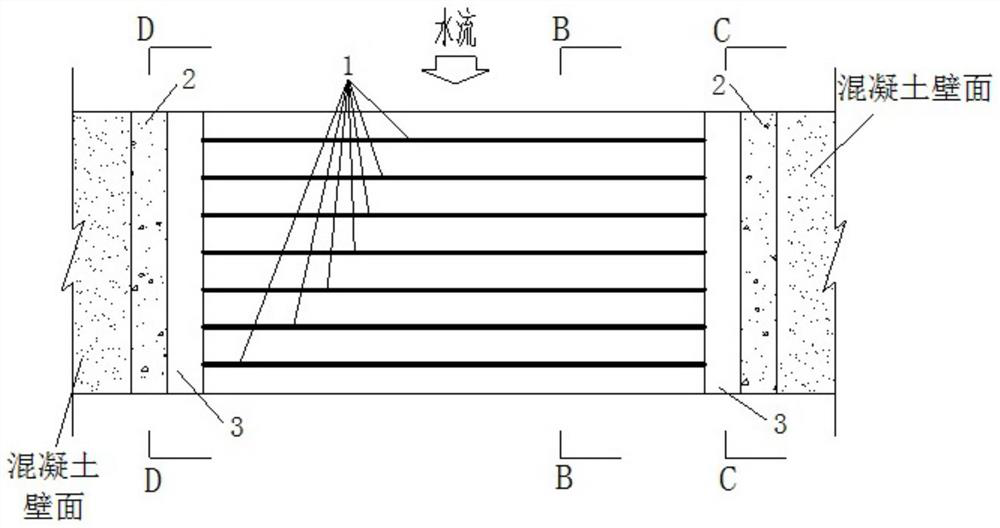

[0026] The self-rotating anti-clogging bottom grid fence that present embodiment provides, as figure 2 As shown, along the water flow direction, a number of grid bars 1 perpendicular to the water flow direction are arranged at equal intervals on the top of the water inlet of the water intake corridor. Each end is equipped with a water impact drive mechanism.

[0027] Such as Figure 3 to Figure 5 As shown, the grid bars used in this embodiment have a cylindrical structure, and the interval between two adjacent grid bars is 0.05-0.2 m.

[0028] Such as Figure 5 As shown, the bearings used in this embodiment are ball bearings, and the ball bearings are fixed in the concrete walls on both sides of the water intake corridor, and the ball bearings and the grid bars are in interference fit.

[0029] Such as Figure 4 As shown, the water impact driving mechanism includes a sprocket 4 fixedly installed at both ends of the grid and a chain 5 matched with all the sprockets. The c...

Embodiment 2

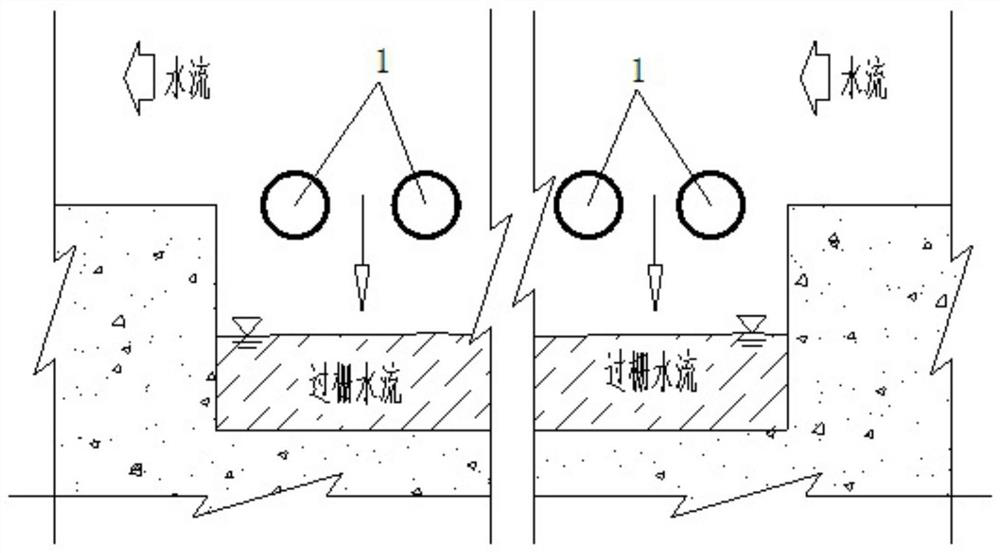

[0033] The self-rotating anti-clogging bottom grill provided in this embodiment is based on the bottom grill provided in Embodiment 1, and further improves the water flow impact driving mechanism.

[0034] The water flow impact driving mechanism provided in this embodiment, such as Figure 7 As shown, it includes pulleys 7 fixedly installed at the two ends of the grid bar and a drive belt 8 matched with all the pulleys. The pulley 7 is a grooved structure wheel, and the width of the groove matches the width of the transmission belt. A number of impact buckets are evenly arranged on the outside of the transmission belt along its circumference to receive the impact of the water flow. The impact bucket is a cone-shaped bucket structure. The interval between two adjacent impact buckets is 0.1-0.5m.

[0035] The anti-blocking principle of the self-rotating anti-clogging bottom grid provided in this embodiment is the same as that in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com