Wet dust collector for food processing workshop

A wet dust collector, food processing technology, applied in the direction of using liquid separation agent, chemical instruments and methods, separation methods, etc., can solve the problems of affecting the recycling of purified water, inconvenient cleaning of the dust box, insufficient energy saving and environmental protection, etc., to achieve reduction Effect of waste, improvement of effect and stability, improvement of dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

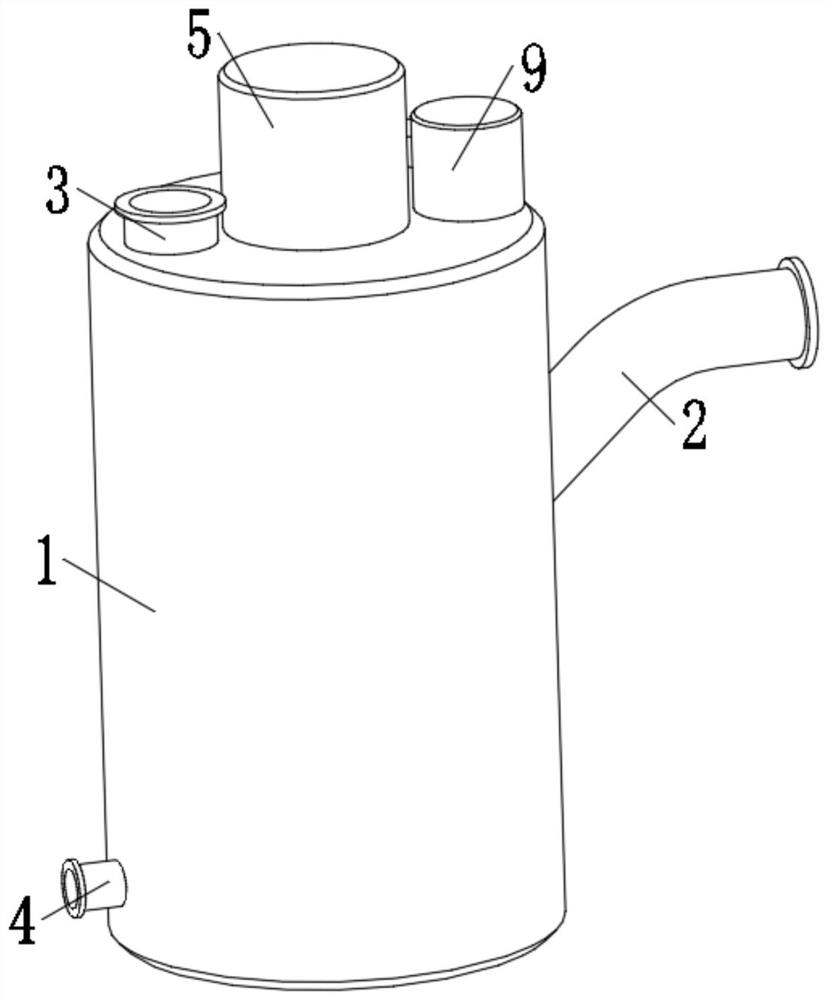

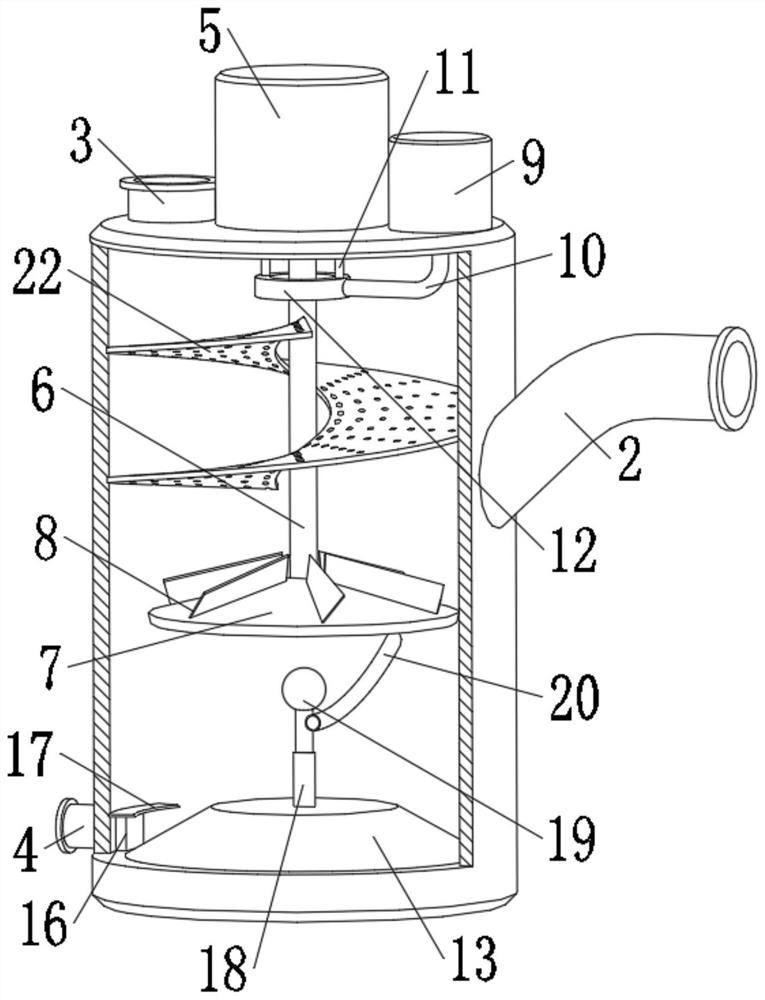

[0029] like figure 1 , image 3 , Figure 4 , Figure 5 and Image 6 As shown, a wet dust collector for a food processing workshop proposed by the present invention includes a dust removal box 1, an air intake pipe 2 is installed outside the dust removal box 1, and the end of the air intake pipe 2 close to the dust removal box 1 is inclined. 2 is communicated with the dust removal box 1, the top of the dust removal box 1 is installed with an exhaust pipe 3, and the exhaust pipe 3 is connected with the dust removal box 1. There is a dust removal and sewage discharge mechanism;

[0030] The dust removal and sewage discharge mechanism includes a rotating shaft 6 that is rotatably connected inside the dust removal box 1. A drive motor 5 is installed on the side of the dust removal box 1 close to the exhaust pipe 3. The drive motor 5 is located at the center of the top of the dust removal box 1, and the output of the drive motor 5 is The end is connected with the rotating shaf...

Embodiment 2

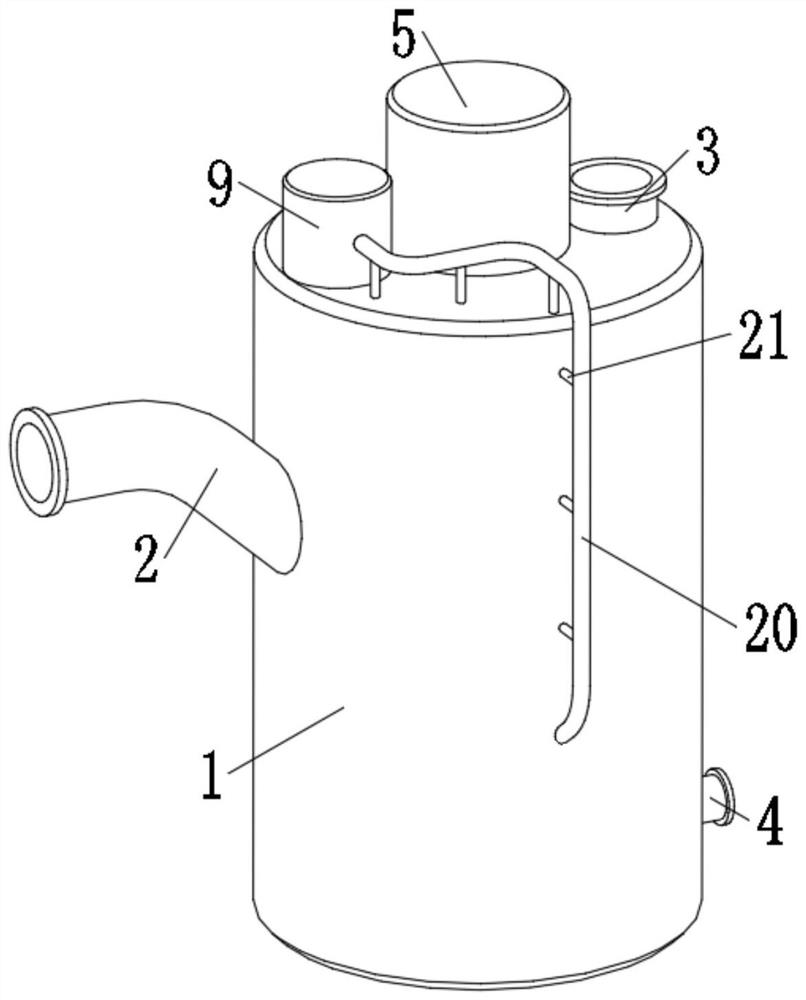

[0035] like Figure 1-3 As shown, based on the first embodiment, the adaptive component includes a telescopic rod 18 installed on the top of the base 13, the telescopic rod 18 is located at the center of the base 13, and a floating ball 19 is installed on the end of the telescopic rod 18 away from the base 13, and the telescopic rod 18 is telescopic. A connecting pipe 20 is installed between the rod 18 and the water pump box 9. One end of the connecting pipe 20 is located below the floating ball 19, and the other end of the connecting pipe 20 is connected with the water pump box 9. Passing through to the outside, a plurality of positioning rods 21 are installed together between the connecting pipe 20 and the outside of the dust box 1 .

[0036] In this embodiment, during the dust removal process, with the continuous increase of impurities and water, the impurities will fall between the dust removal box 1 and the base 13 along the inner wall of the dust removal box 1, and the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com