Flocked cloth cooling mechanism

A technology of cooling mechanism and flannelette, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., which can solve the problems of long production cycle, inconvenient operation, and inability to move, and achieve uniform spraying water and simple structure , high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

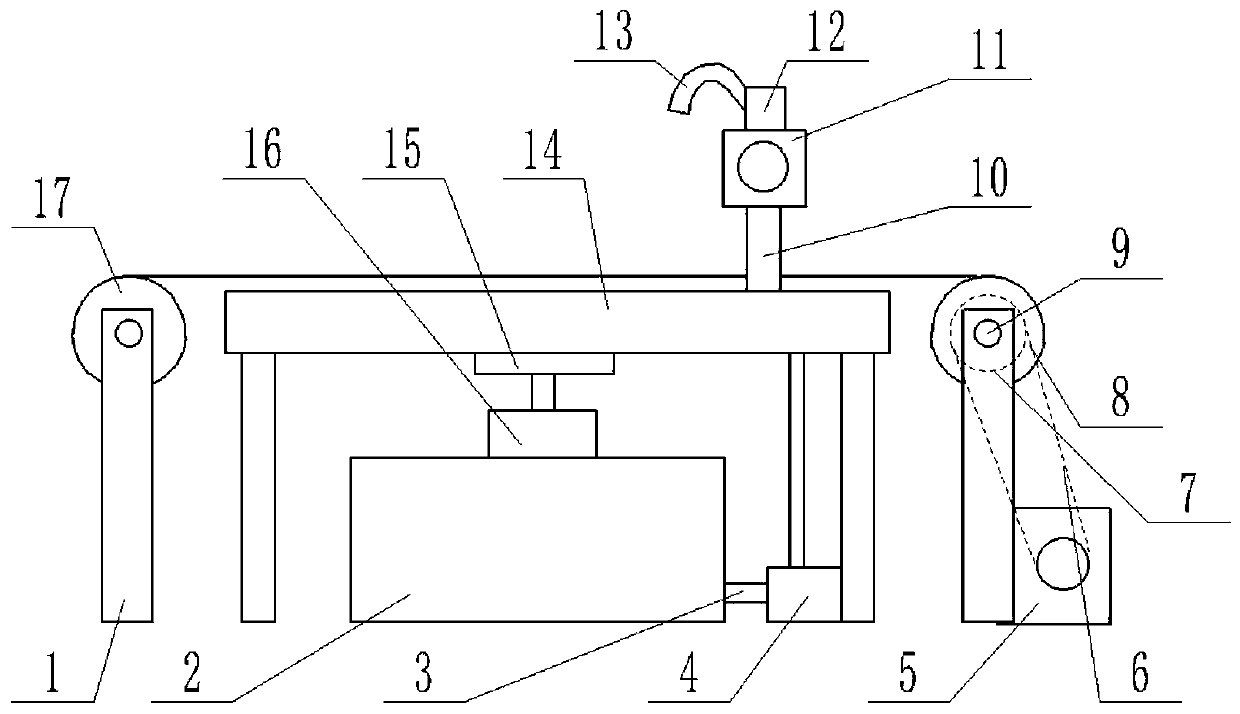

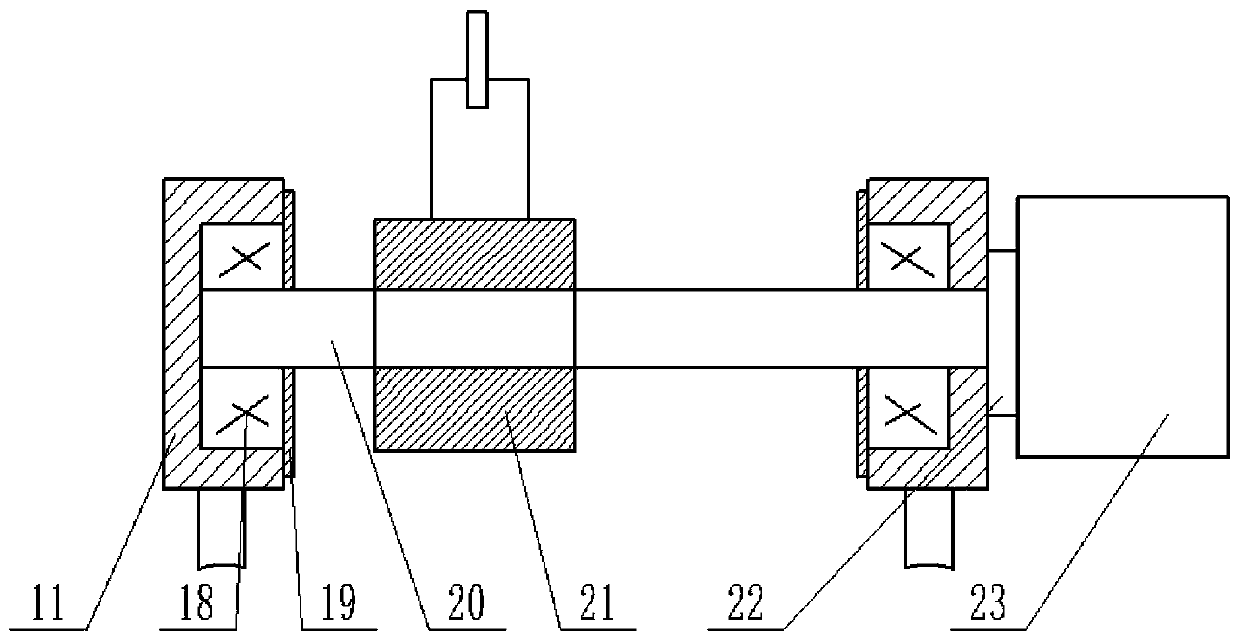

[0019] Such as Figure 1-Figure 3 As shown, a cooling mechanism for flocking cloth includes a column 1, a water tank 2, a water pipe 3 and a water pump 4. A discharge roller 17 and a collection roller 8 are installed on the column 1, and the column 1 passes through the discharge roller 17 and the collection roller 8. The rotating shaft 9 is connected, and a water tank 14 is provided on one side of the discharge roller 17, and a water return port 15 is provided below the water tank 14, and the water return port 15 is connected to the filter 16, and the filter 16 is connected to the water tank 2, and the water tank 2 is connected to the water pump through the water pipe 3 4 connection, the water pump 4 is connected with the water spray pipe 13, the water spray pipe 13 is fixed on the fixed block 12, the fixed block 12 is connected with the lead screw nut 21, the lead screw nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com