A kind of equipment for repairing seams of floor tiles for decoration

A tile and seam repair technology, which is applied in the field of floor tile seam repair equipment for decoration, can solve the problems of affecting work efficiency, internal hollowness, and inability to compact tile beauty seam repair agents, etc., to achieve stable movement and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

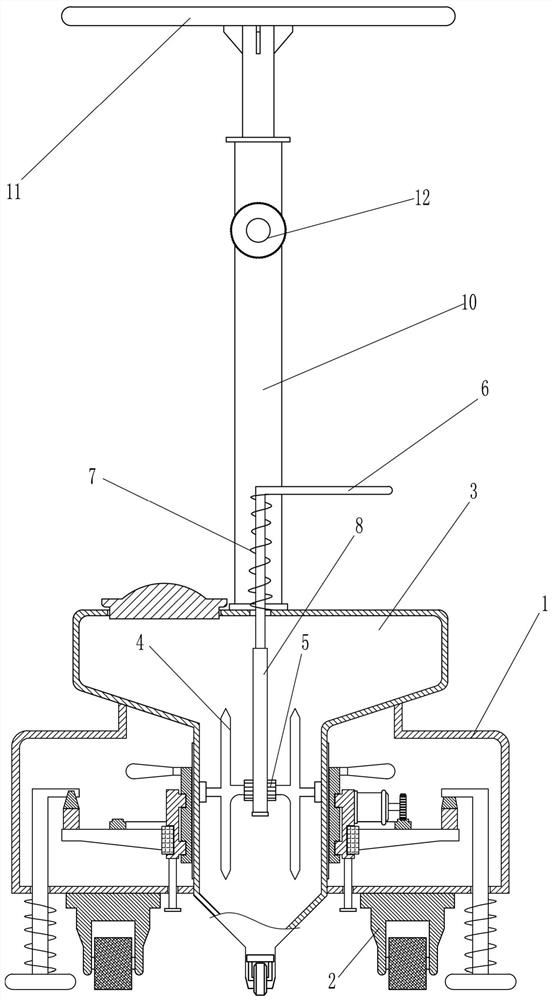

[0018] see figure 1 , a floor tile seam repairing equipment for decoration, including an organic casing 1, a walking wheel 2 and a storage tank 3, the bottom of the casing 1 is provided with a walking wheel 2 that facilitates the movement of the device, the walking wheel 2 is a universal wheel, and the machine The shell 1 is provided with a storage tank 3, and also includes a stirring paddle 4, a toothed roller 5, an L-shaped guide rod 6, a return spring 7 and a rack 8, and a stirring paddle is rotatably connected between the two walls of the storage tank 3. 4. The middle part of the stirring paddle 4 is connected with a toothed roller 5, and the toothed roller 5 and the stirring paddle 4 are connected through an interference connection. The top of the storage tank 3 is slidingly provided with an L-shaped guide rod 6, and the top of the L-shaped guide rod 6 A return spring 7 is connected to the top of the storage tank 3, and a rack 8 is connected to the bottom of the L-shaped ...

Embodiment approach 2

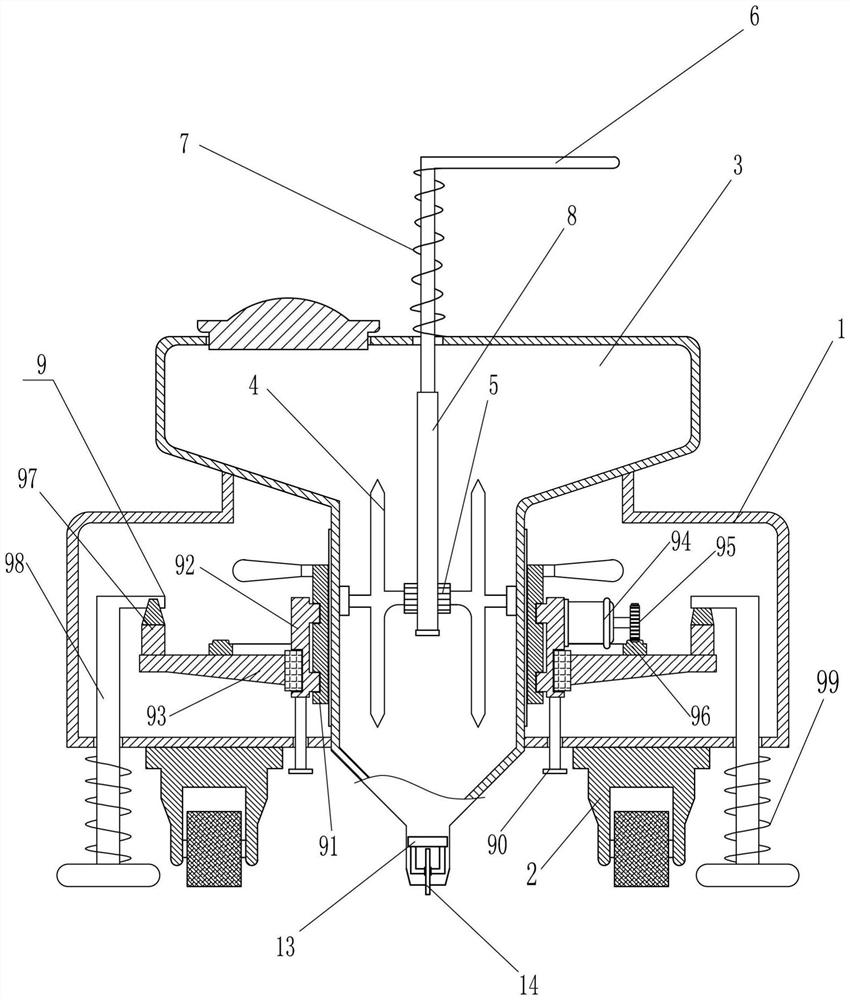

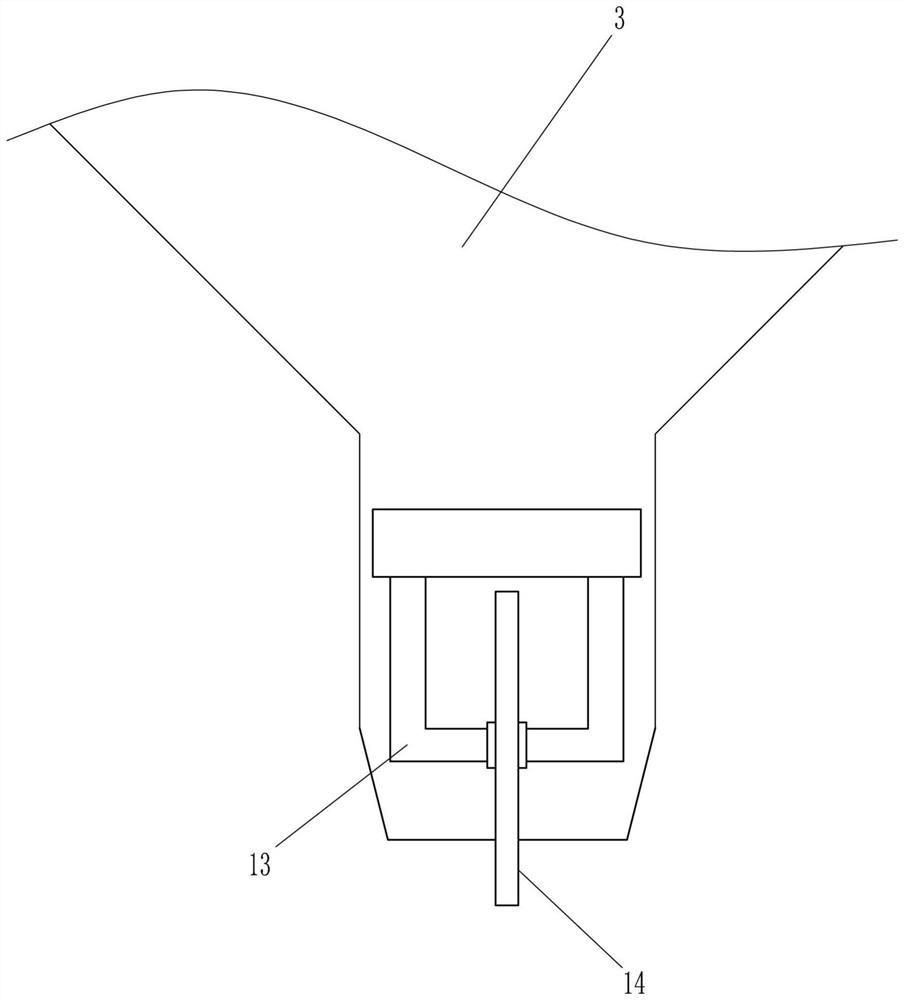

[0021] see figure 2 and Figure 4 , also includes a vibration device 9, the vibration device 9 includes a guide rod 90, a threaded sleeve 91, a slip ring 92, an annular plate 93, a reduction motor 94, a gear 95, an annular ring gear 96, a wedge-shaped protrusion 97, and an L-shaped hammer Rod 98 and tension spring 99, material storage tank 3 outer threaded sleeves 91 are connected to the outer side, and the threaded sleeves 91 are located in the casing 1, and the outer sides of the threaded sleeves 91 are rotatably connected with sliding rings 92, and the bottoms of the sliding rings 92 are left and right. Both sides are provided with guide rods 90, the guide rods 90 are connected with the sliding ring 92 through threaded connection, the guide rods 90 are slidingly matched with the casing 1, and the outer side of the sliding ring 92 is slidably provided with an annular plate 93, and the sliding ring 92 is parallel to The casing 1 is provided with a reduction motor 94 on the ...

Embodiment approach 3

[0024] see figure 1 , also includes a connecting pipe 10, a connecting frame 11 and a fastening knob 12, a connecting pipe 10 is arranged in the middle of the top of the storage tank 3, and the connecting pipe 10 is connected with the storage tank 3 through a bolt connection, and the connecting pipe 10 slides The connection frame 11 is arranged in the formula, the interior of the connection pipe 10 is hollow, and the connection pipe 10 is provided with a fastening knob 12, and the fastening knob 12 is used to connect the connection pipe 10 and the connection frame 11.

[0025] When the device needs to be moved, you can hold the connecting frame 11 to drive the device to move. When you need to adjust the height of the connecting frame 11, you can loosen the fastening knob 12, and then you can pull the connecting frame 11 to move up and down for adjustment. After the adjustment, Tighten the fastening knob 12 to fix the connecting frame 11, and when holding the connecting frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com