Special bracket for pipe rack elevated polyurethane insulation pipe and construction method thereof

A technology of polyurethane and thermal insulation pipes, applied in the direction of pipeline support, thermal insulation, pipeline protection, etc., can solve the problems of unsuitability for engineering applications, small use range, high production cost, etc., and achieve the effects of low cost, long service life and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

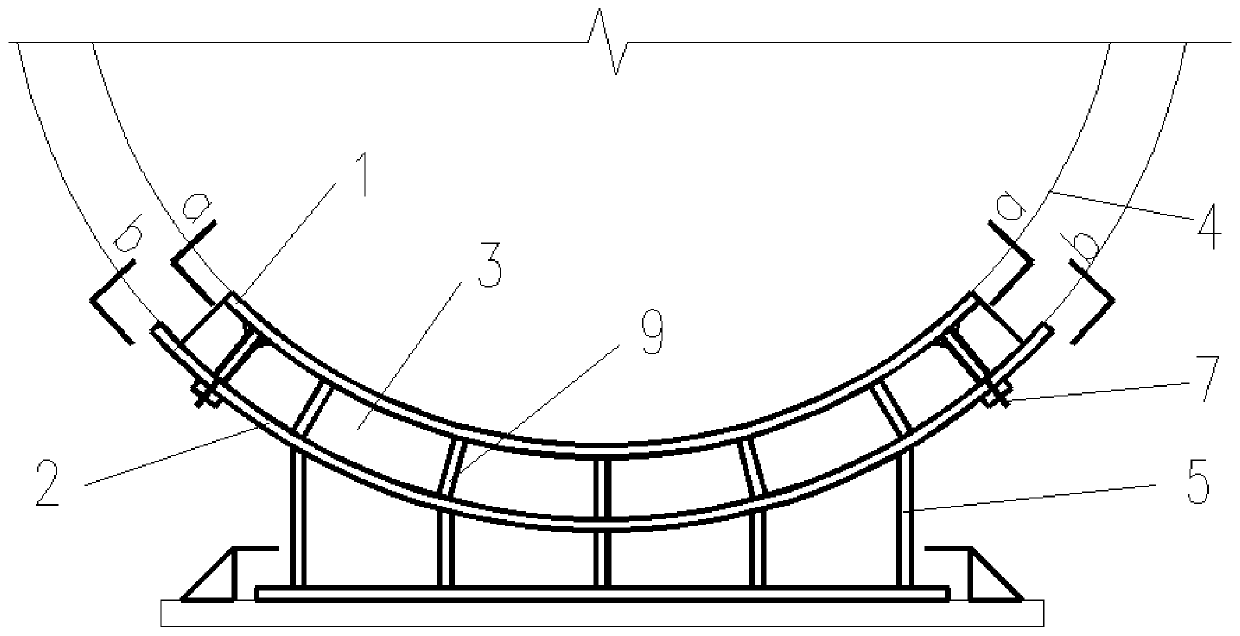

[0029] Attached below figure 1 , 2 , 3 and specific embodiments, further elaborate the present invention.

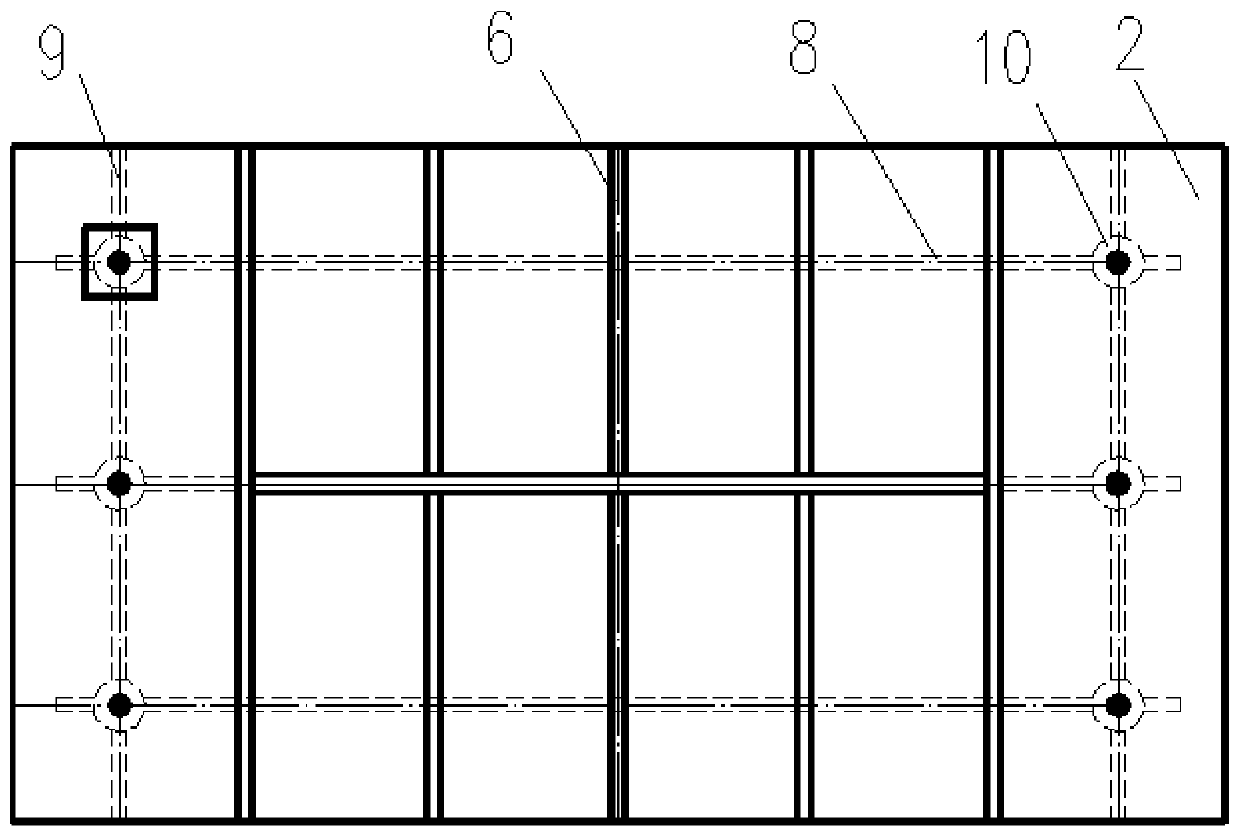

[0030] The present invention provides a special bracket for overhead polyurethane thermal insulation pipes in a pipe gallery, comprising an inner bracket 1 and an outer bracket 2, the inner bracket 1 is connected to the working steel pipe 4 of the polyurethane thermal insulation tube, and the outer bracket 2 is connected to the outer bracket column 6 through the outer bracket The outer bracket supporting plate 5 is connected, and the inner bracket 1 and the outer bracket 2 are connected by fixing bolts 7 of the inner and outer brackets to form a thermal insulation layer 3 .

[0031] Further, the insulation layer 3 is a polyurethane insulation layer.

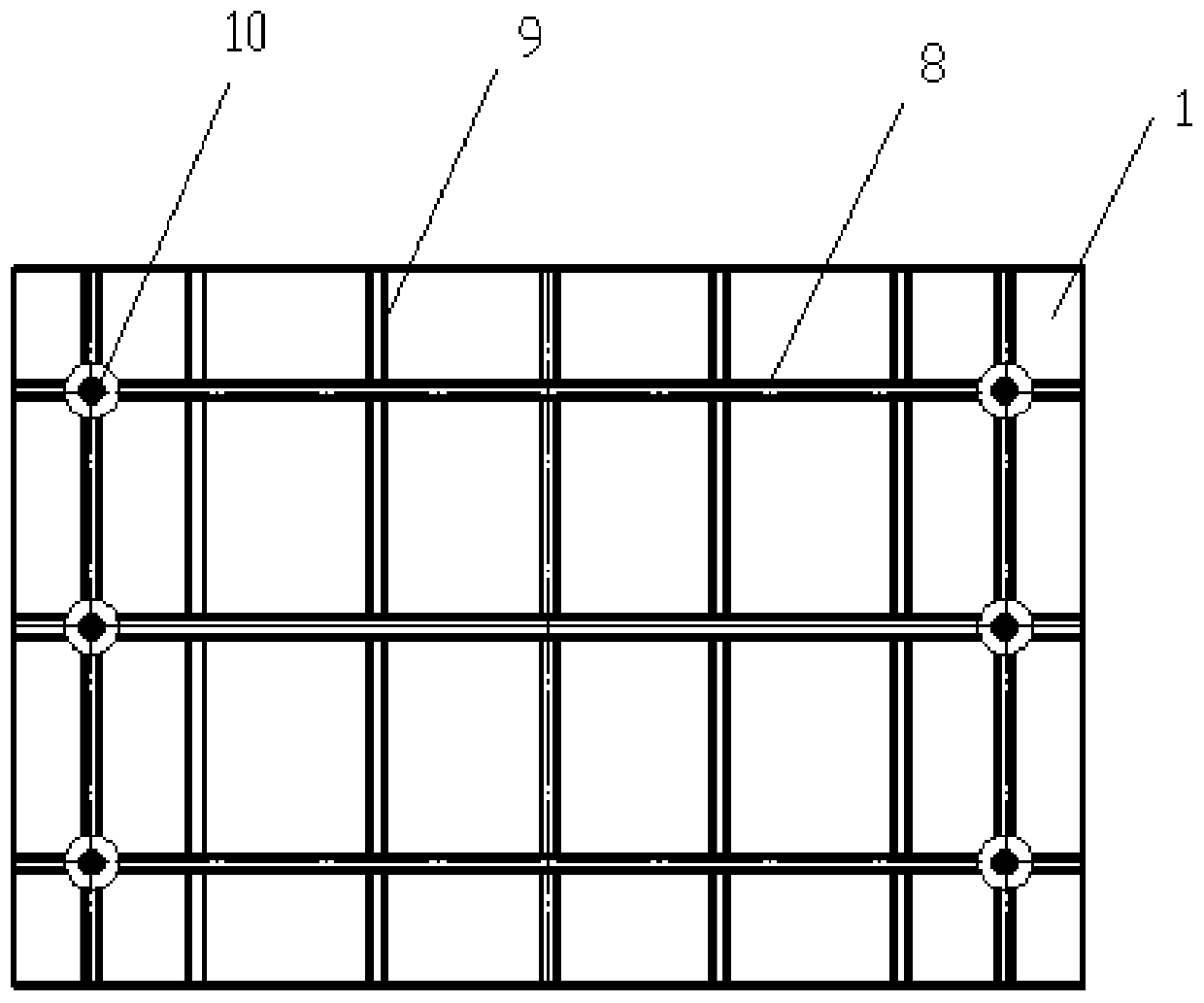

[0032] Further, the inner bracket 1 is an arc-shaped steel plate provided with transverse ribs 8 and longitudinal ribs 9 .

[0033] Further, bolt holes 10 are provided on the longitudinal ribs 9 on both sides of the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com