Interior trim surface material

A technology for surface materials and interior decoration, applied in the field of surface materials for interior decoration, can solve problems such as insufficient tactility, and achieve the effect of excellent tactility and strong moisturizing feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0200] The printing liquid A was applied to the adhesive-attached surface of the adhesive-bonded nonwoven fabric using a cylinder, and then dried with a dryer at a temperature of 150°C.

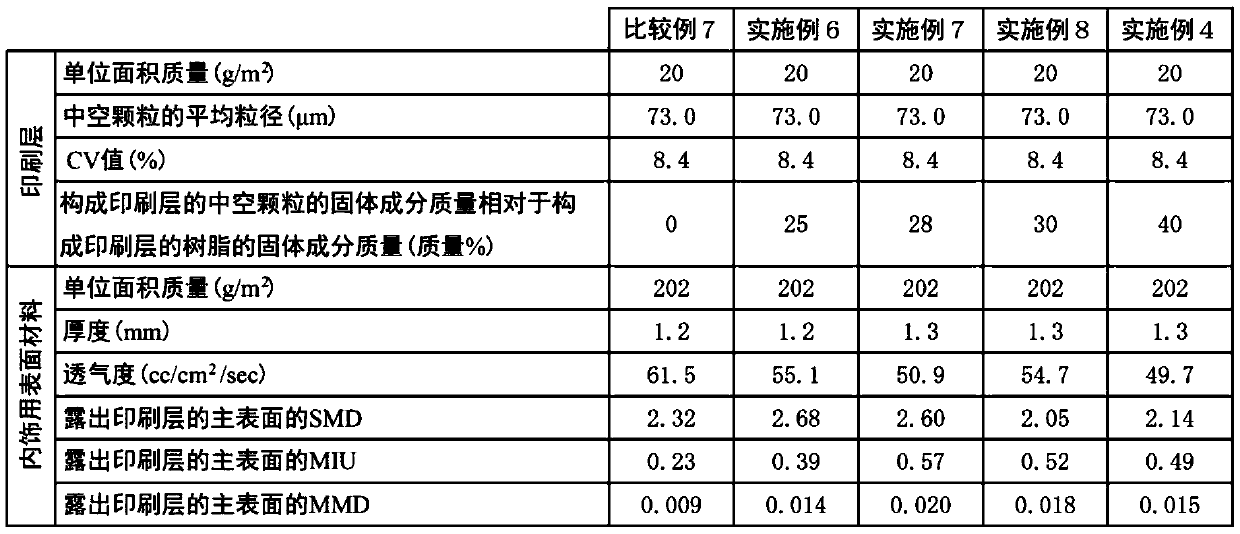

[0201] And, finally, it is supplied to a Reliant Press machine (temperature: 150° C., pressing pressure: 2 kgf, processing time: 12 seconds), thereby manufacturing an adhesive-bonded non-woven fabric with printing from printing solution A on one main surface. The surface material for the interior of the layer (mass per unit area: 212g / m 2 , thickness: 1.3mm, air permeability: 46.1cc / cm 2 / sec, mass per unit area of the printing layer: 30g / m 2 , average particle diameter of hollow particles: 73.0 μm, CV value: 8.4%).

[0202] The SMD of the main surface where the printed layer was exposed of the surface material for interior manufactured in this way was 2.09 micrometers, MIU was 0.45, and MMD was 0.015.

Embodiment 2

[0204] Except using printing liquid B instead of printing liquid A, in the same manner as in Example 1, a surface material for interior decoration ( Mass per unit area: 212g / m 2 , thickness: 1.4mm, air permeability: 55.5cc / cm 2 / sec, mass per unit area of the printing layer: 30g / m 2 , average particle diameter of hollow particles: 105.6 μm, CV value: 15.9%).

[0205] The SMD of the main surface where the printed layer was exposed of the surface material for interior manufactured in this way was 2.21 micrometers, MIU was 0.45, and MMD was 0.015.

Embodiment 3

[0222] Except that the processing time of the Reliant Press machine was changed to 20 seconds, in the same manner as in Example 1, a printed layer from printing liquid A was produced on one main surface of the adhesive bonded nonwoven fabric. Surface material (mass per unit area: 212g / m 2 , thickness: 1.1mm, air permeability: 42.4cc / cm 2 / sec, mass per unit area of the printing layer: 30g / m 2 , average particle diameter of hollow particles: 73.0 μm, CV value: 8.4%).

[0223] The SMD of the main surface where the printed layer was exposed of the surface material for interior manufactured in this way was 1.98 micrometers, MIU was 0.44, and MMD was 0.012.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com