Special down-proof rubber strip lining for down jacket

A technology of anti-drilling and down jackets, which is applied in clothing, clothing, applications, etc., can solve the problems of down jackets and down jackets, and achieve soft hand feeling, avoid easy-running down, and good anti-drilling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

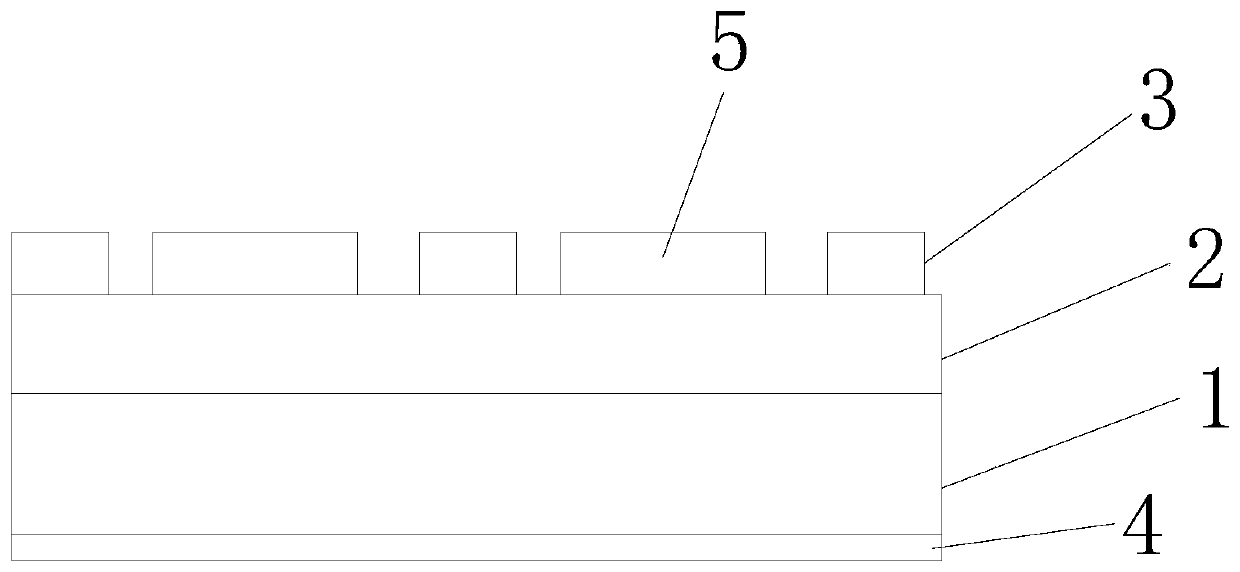

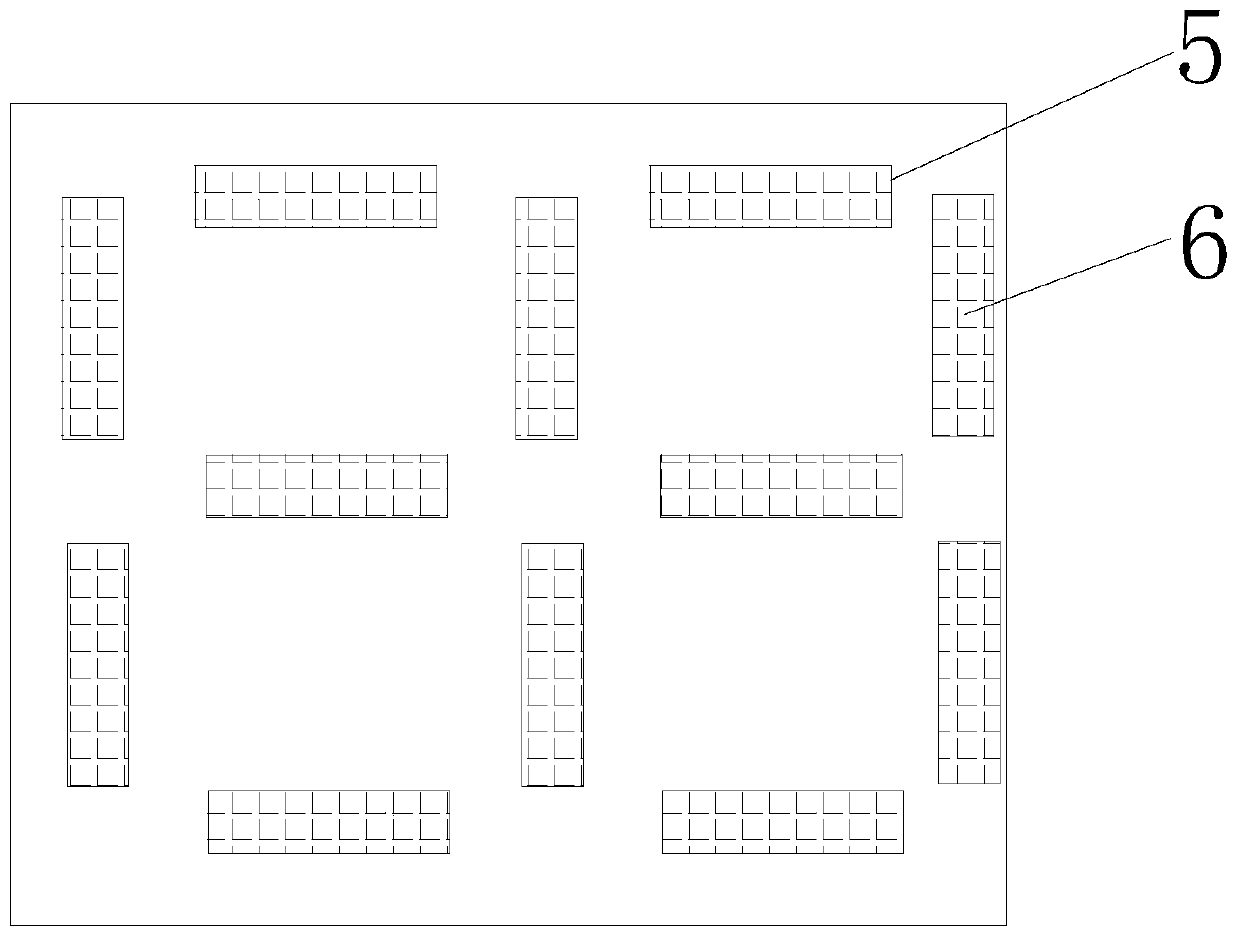

[0020] refer to figure 1 with figure 2 , a special anti-drilling rubber strip lining for down jackets according to the present invention, comprising a woven base fabric layer 1, an anti-down coating layer 2, and a rubber strip adhesive layer 3, and the woven base fabric layer 1 is made of composite low-elastic polyester yarn As the warp and weft, it is formed by twill weaving. The upper surface of the woven base fabric layer 1 is compounded with an anti-velvet coating layer 2, and the upper surface of the anti-velvet coating layer 2 is provided with a strip adhesive layer 3, The composite low-elastic polyester yarn is twisted by two 75D / 48F polyester low-elastic yarn and one 75D / 24F polyester sea-island yarn, and the twist direction of the composite low-elastic polyester yarn is "SSS" and "ZZZ" Any one of them, the woven base fabric layer 1 and the fleece-proof coating layer 2 are compounded and subjected to soft and water-repellent treatment, the fleece-proof coating layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com