Tobacco barn loading device convenient and fast to use

A cigarette warehouse and convenient technology, applied in the field of cigarette warehouse loading equipment, can solve the problems of low efficiency and high labor intensity of workers, and achieve the effects of strong practicability, ingenious structure and novel concept.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

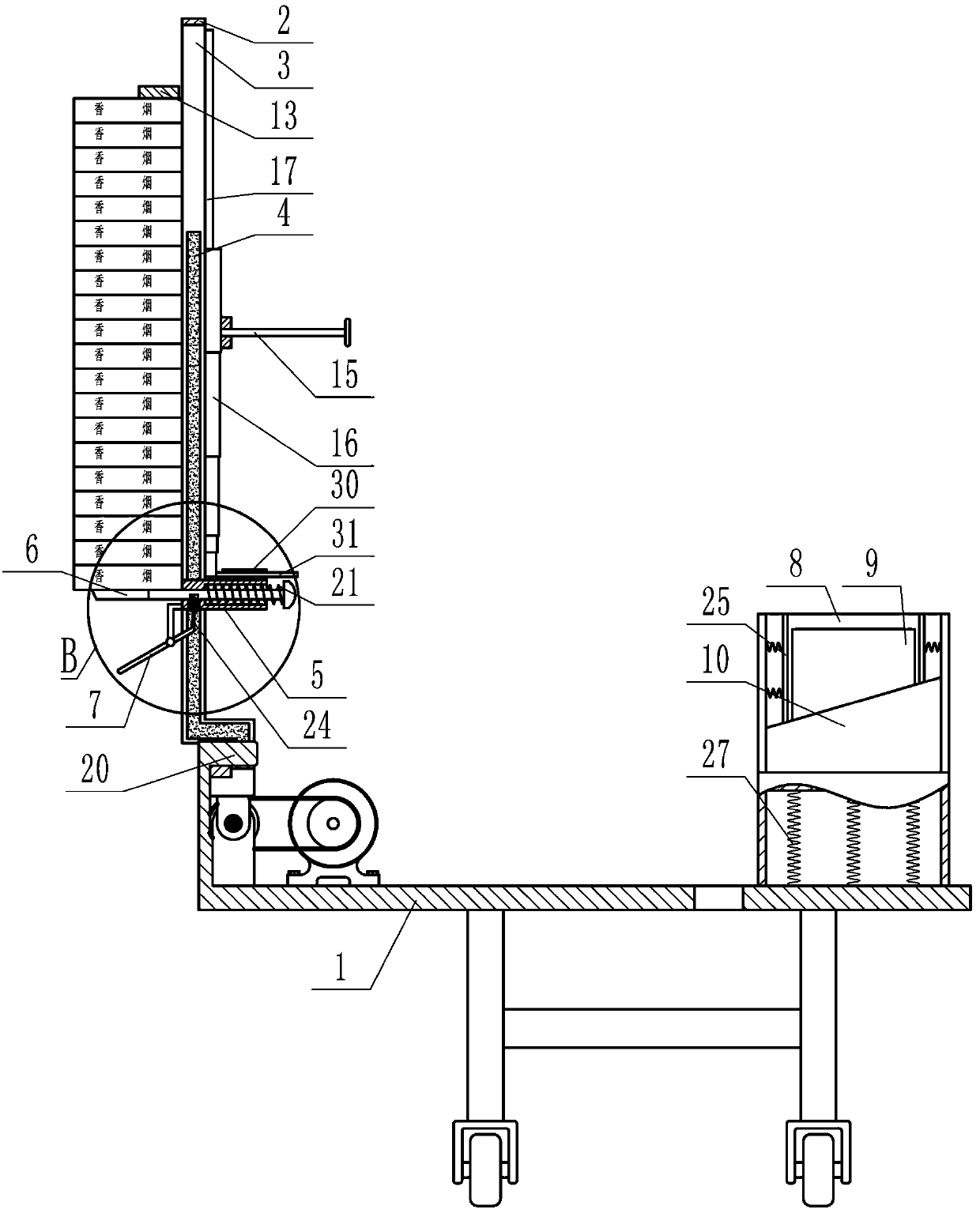

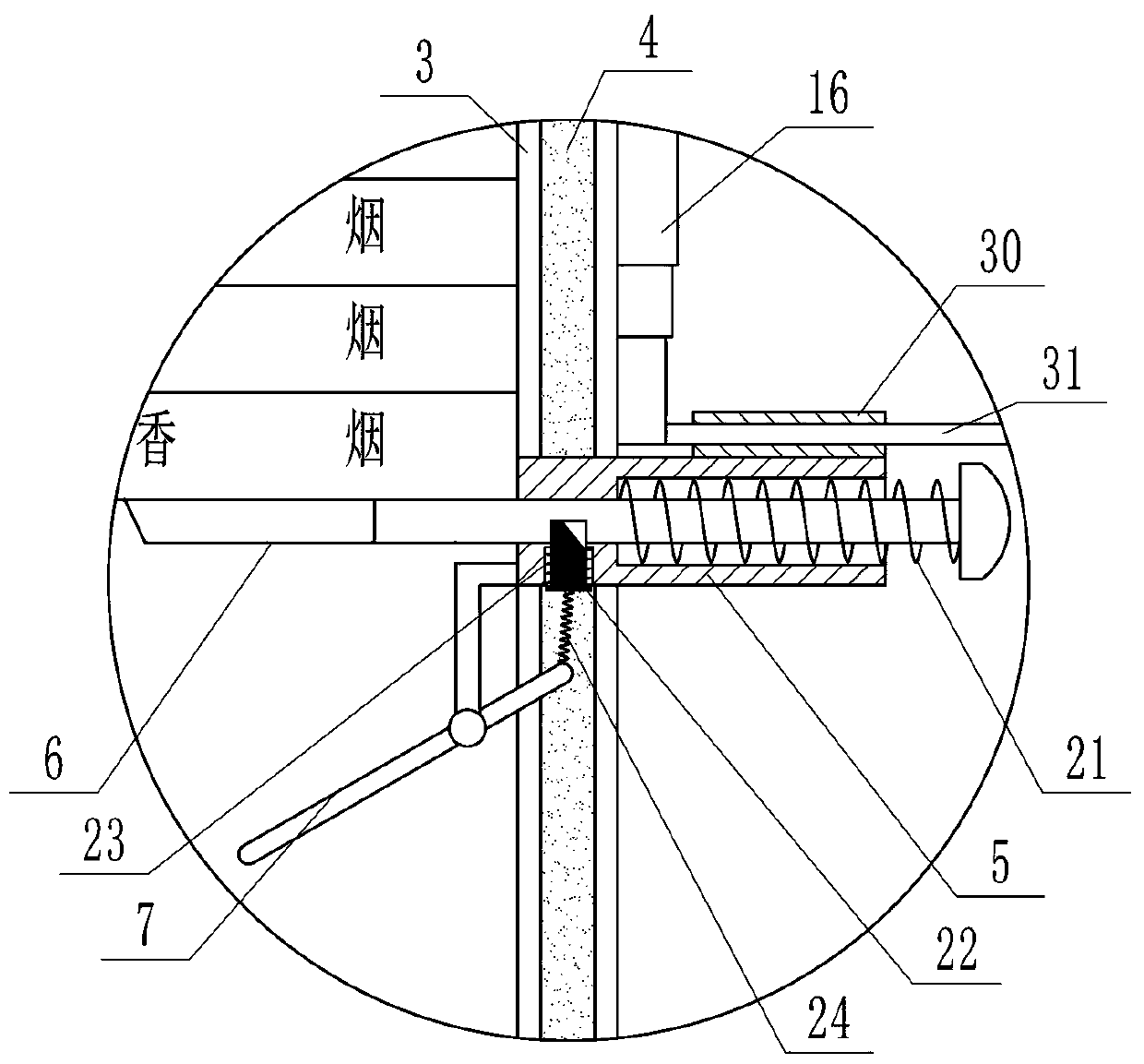

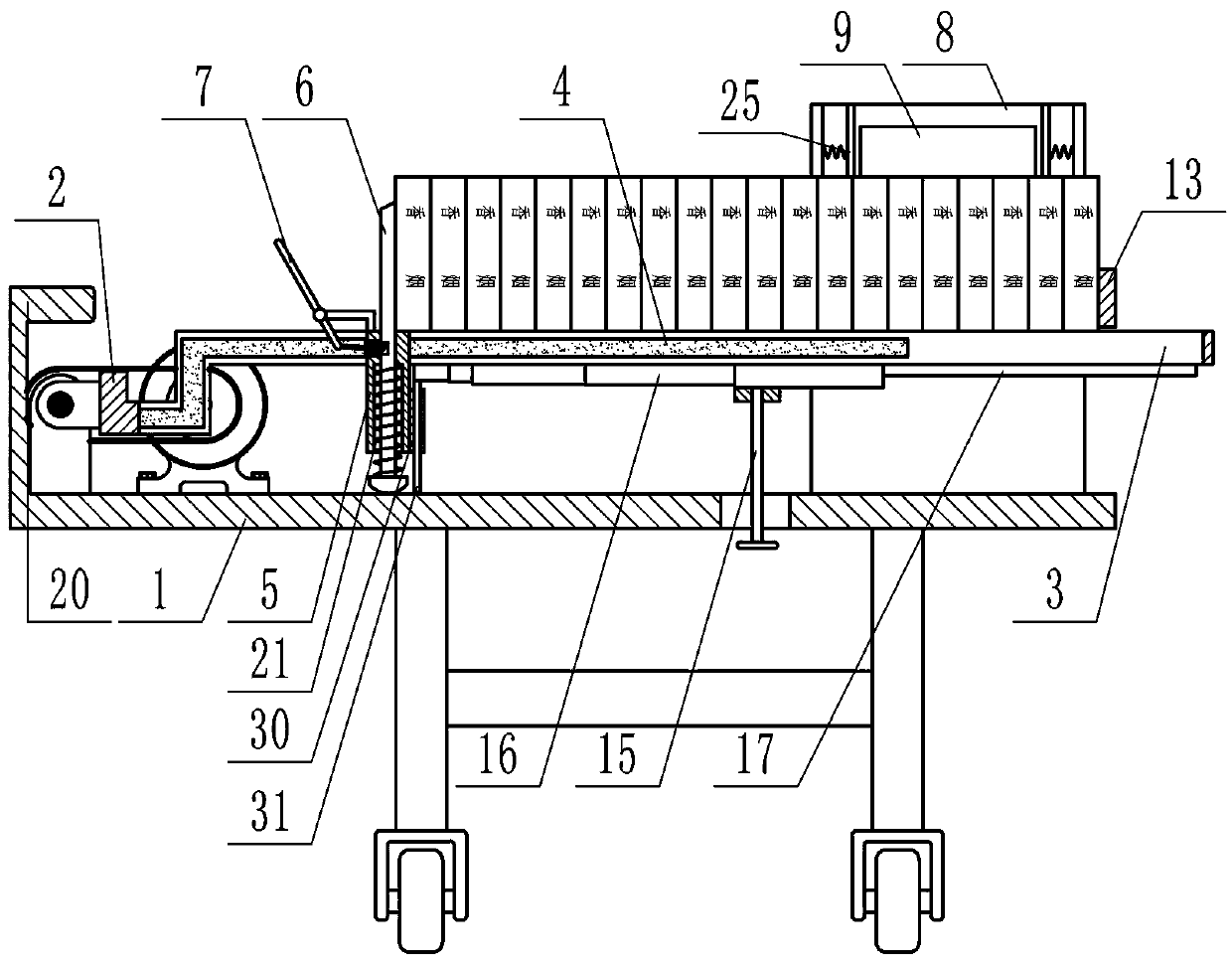

[0016] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

[0017] by Figure 1 to Figure 9 It can be seen that the present invention includes a horizontal platform 1 that can move forward and backward. The left end of the platform 1 is provided with a protrusion, and a vertical plate 2 is hinged on the protrusion. The vertical plate 2 can be rotated clockwise to the level. A through groove 3 is provided. The front and rear side walls of the through groove 3 are each provided with a steel plate 4. When the vertical plate 2 is not upright, the lower ends of the two steel plates 4 have a tendency to squeeze toward the middle. The housing 5 slides up and down in the through slot 3. A spring plate 6 that is perpendicular to the vertical plate 2 and has a tendency to move to the right is installed in the housing 5, and a rotating rod 7 is provided under the housing 5. Turn clockwise to make the bull...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap