A device for increasing beating concentration

A concentration and equipment technology, applied in pulp beating/refining methods, textiles and papermaking, papermaking, etc., can solve the problems of low paper strength, inability to improve beating concentration, poor toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

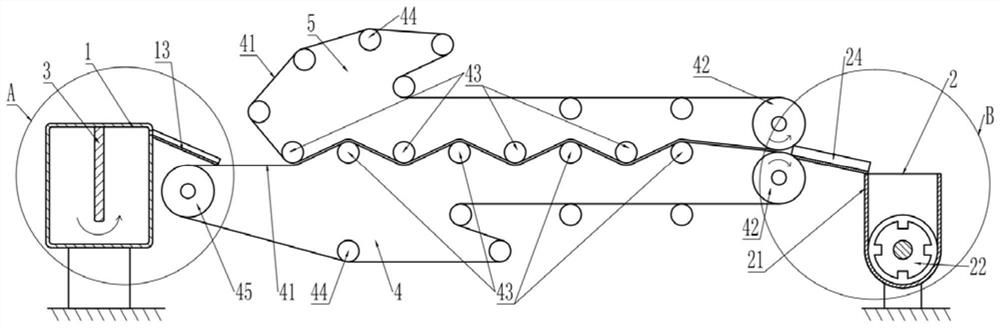

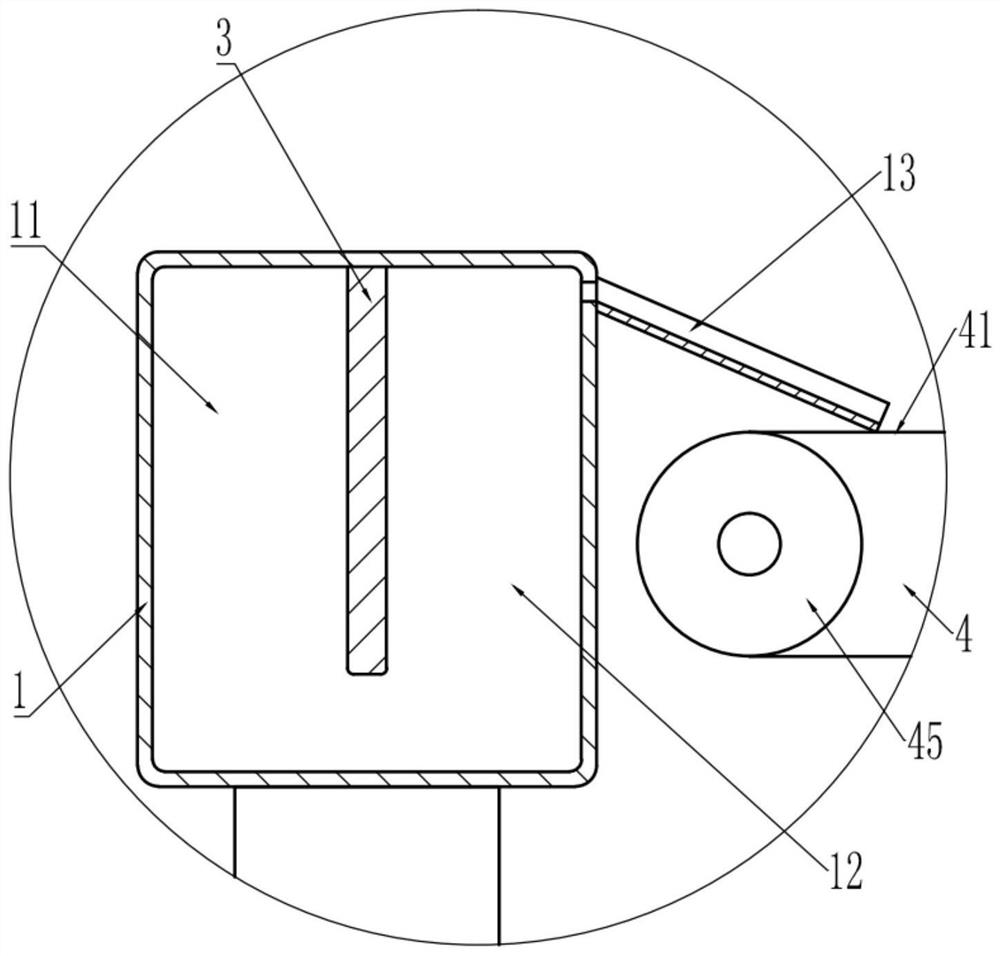

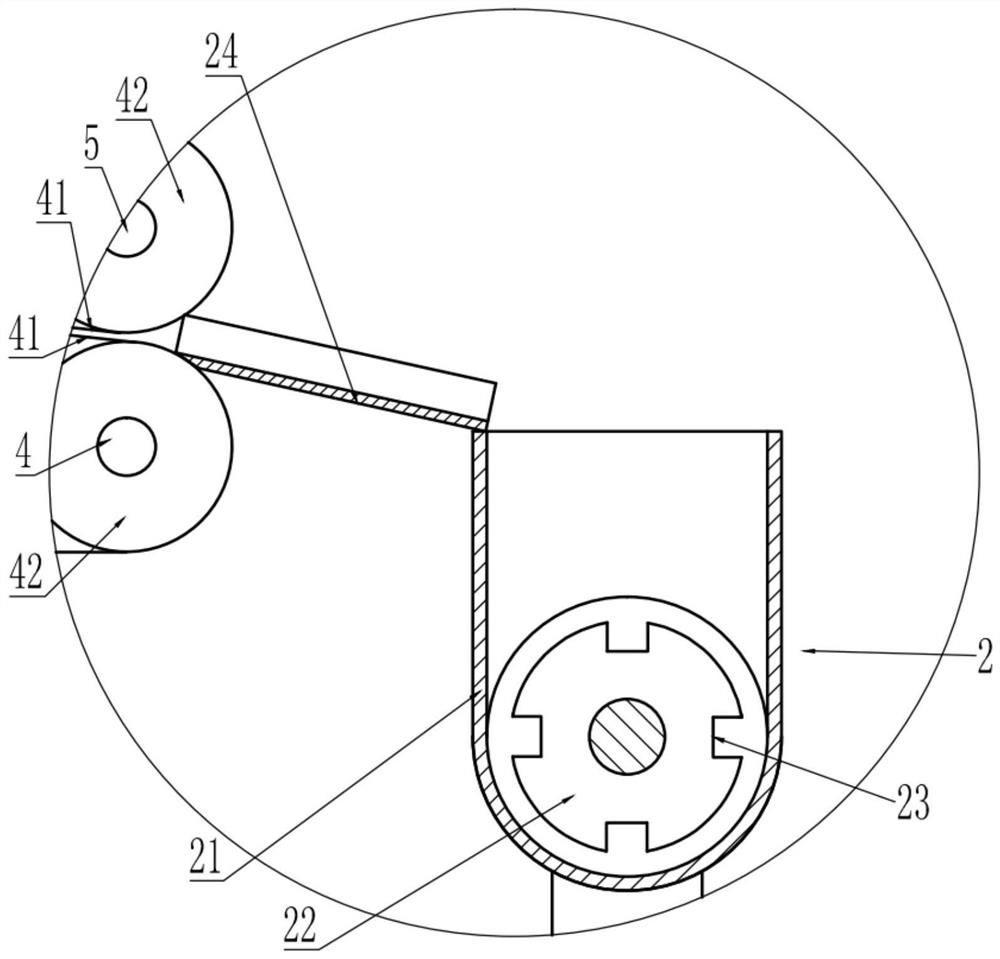

[0035] Embodiment one is basically as attached Figure 1 to Figure 4 Shown:

[0036] A device for improving beating concentration, comprising a material box 1, a frame, a traction group and a screw propeller 2, the material box 1, the frame and the screw propeller 2 are installed on the ground, and the traction group is installed on the frame; the material box 1 is welded with a partition 3, the top of the feed box 1 is closed, and an overflow pipe is installed at the bottom of the feed box 1 near the slurry chamber 11. There is a certain distance between the bottom of the partition 3 and the bottom of the feed box 1, and the partition 3 separates the feed box It is divided into a pulp inlet chamber 11 and a pulp outlet chamber 12, and a pulp outlet is opened on the right side wall of the pulp outlet chamber 12 of the head box 1 .

[0037] The traction group includes a first traction group 4 and a second traction group 5, the first traction group 4 is located below the second...

Embodiment 2

[0048] Embodiment two is basically as attached Figure 5 As shown, on the basis of Embodiment 1, Embodiment 2 adds a ventilation pipe 6 that is fixedly connected to the frame by bolts. The papermaking wire 41 of the first traction group 4 passes through the ventilation pipe 6, and the right side of the ventilation pipe 6 communicates. There is an air supply pipe 7 of a blower fan, and several air deflectors 8 are welded in the ventilation pipe 6. The left side of the ventilation pipe 6 bends downward, and the bottom left side of the ventilation pipe 6 is equipped with a collection box 9 for easy water receiving; The top surface and the bottom of the ventilation pipe 6 are all inclined downward from right to left, so that the water falling to the top of the ventilation pipe 6 and the water inside the ventilation pipe 6 can flow into the collection box 9 obliquely downward, so as to facilitate the collection of water .

[0049] The specific implementation process is as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com