A poultry feed feeding device for aquaculture

A technology of feeding device and breeding industry, applied in poultry industry, application, animal husbandry, etc., can solve the problems of wasted labor, overcrowded food, burden of poultry breeding, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

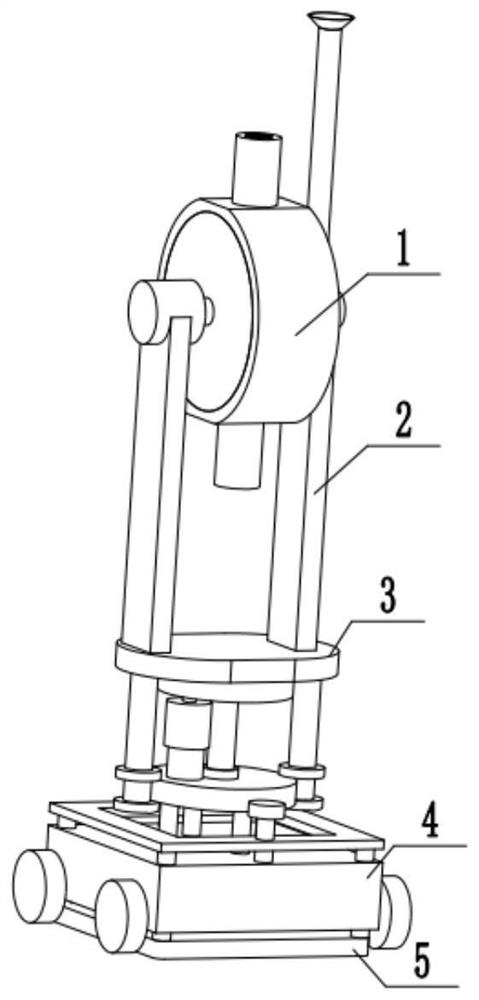

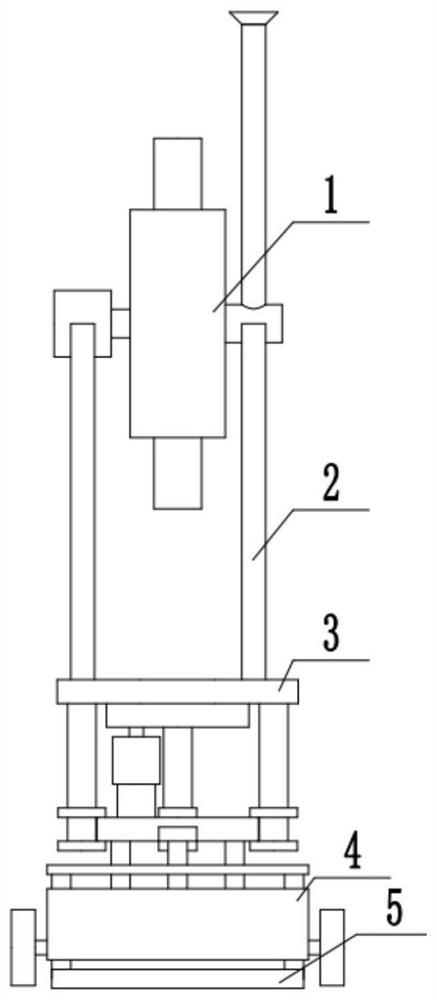

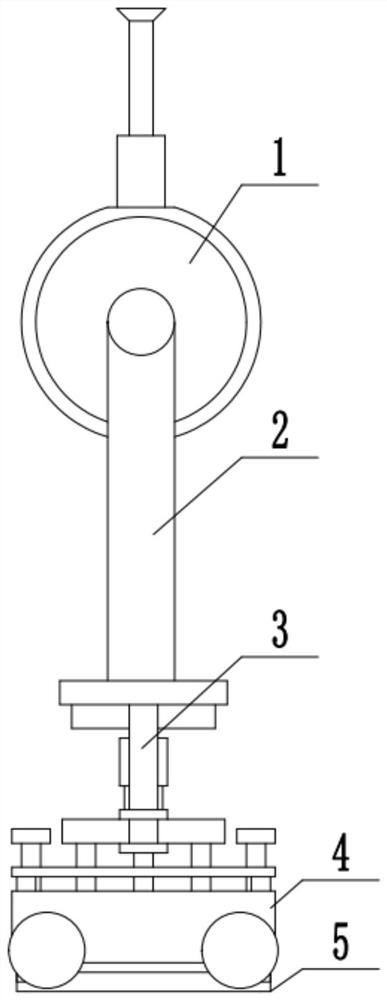

[0038] Combine below figure 1 , 2 , 3 Description of the present embodiment, a poultry feed feeding device for aquaculture, including a feed feeding device 1, a support frame 2, a rotating device 3, a mobile base 4 and a fixing device 5, and the support frame 2 is fixedly installed on the feed feeding device. On the device 1 , the other end of the support frame 2 is fixedly installed on the rotating device 3 , the rotating device 3 is fixedly installed on the moving base 4 , and the fixing device 5 is installed on the moving base 4 .

specific Embodiment approach 2

[0039] Combine below Figure 4 , 5 , 6, 7, 8, and 9 illustrate this embodiment, and this embodiment will further illustrate Embodiment 1. The feed delivery device 1 includes a feed inlet 1-1, a feed addition standpipe 1-2, and a feed addition horizontal pipe 1-3. , feed feeding mechanism 1-4, power motor A1-5, feed inlet 1-1 is fixedly installed above the feed adding standpipe 1-2, feed adding standpipe 1-2 is fixedly installed on the feed adding horizontal pipe 1-3 Above, the feed adding horizontal pipe 1-3 is movably installed on the feed delivery mechanism 1-4, and the output end of the power motor A1-5 is connected to the feed delivery mechanism 1-4 to play the function of feed addition;

[0040]The feed delivery mechanism 1-4 includes a delivery net plug 1-4-1, a delivery tube 1-4-2, a delivery box 1-4-3, a feed addition port 1-4-4, and a delivery net plug 1-4. -1 is fixedly installed on the delivery tube 1-4-2, and there are two delivery tubes 1-4-2, which are respecti...

specific Embodiment approach 3

[0041] Combine below Figure 10 , 11 , 12, and 13 illustrate this embodiment, and this embodiment will further describe Embodiment 1. The described rotating device 3 includes a rotating mechanism 3-1, a support rod A3-2, a sliding block A3-3, and a fixed lower plate 3-4 , fixed bottom column 3-5, motor fixing frame 3-6, power motor B3-7, support bar B3-8, sliding block B3-9, and rotating mechanism 3-1 is fixedly installed on the top of support bar A3-2, supports There are two rods A3-2 and two sliding blocks A3-3, which are respectively fixedly installed on the two supporting rods A3-2, and the fixed lower plate 3-4 is movably installed on the sliding block A3-3. In the draw-in groove, the bottom of the fixed lower plate 3-4 is fixedly installed with a fixed bottom column 3-5, and the fixed bottom column 3-5 is provided with four, and the sliding block B3-9 is movably installed on the fixed lower plate 3-4, and the motor The fixed frame 3-6 is fixedly installed on the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com