Resin-based nano-lanthanum material and preparation method and application thereof

A resin-based, nanotechnology, applied in separation methods, nanotechnology, nanotechnology, etc., can solve the problems of poor uniformity and stability of nano-lanthanum composite materials, achieve uniform distribution of lanthanum nanoparticles, avoid channel blockage, and distribute nanoparticles uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

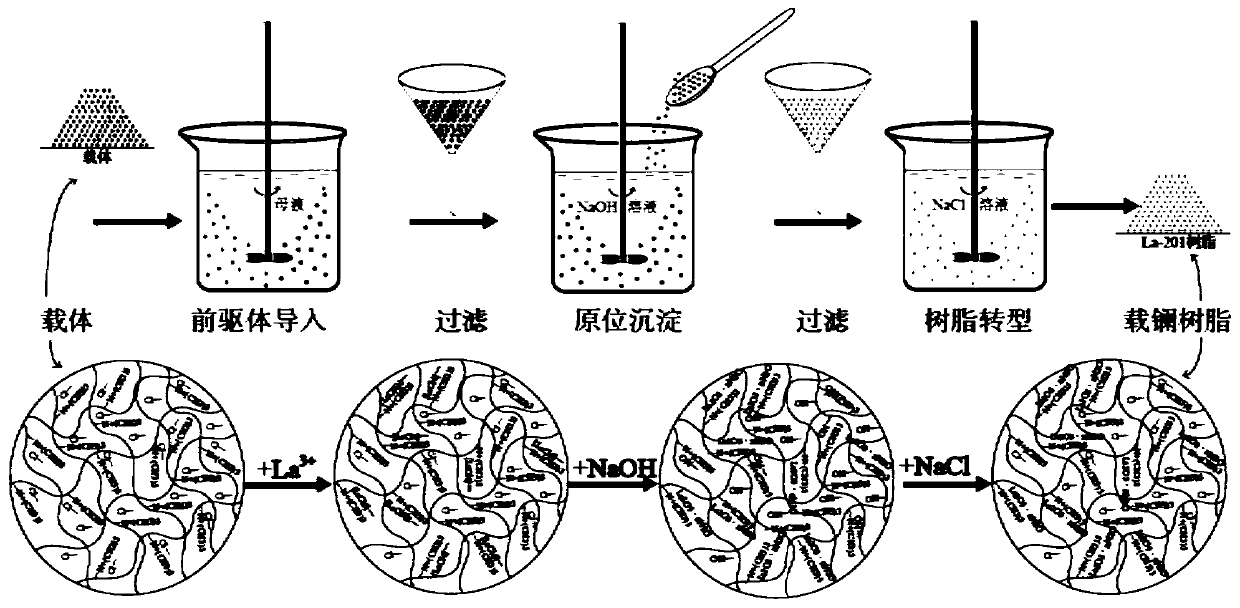

[0054] A preparation method of a resin-based nanometer hydrated lanthanum oxide material, the steps of which are as follows:

[0055] 1) if figure 1 As shown, concentrated hydrochloric acid with a concentration of 12mol / L was added to ethanol to prepare a 1M HCl ethanol solution, and 20g LaCl 3 Dissolve in 200mL 1M HCl ethanol solution, add 10g D-201 resin, stir at 25°C for 16h;

[0056] 2) filtering the above resin to obtain a resin product A that combines lanthanum in an ion exchange manner;

[0057] 3) Add product A to 200mL of 15% NaOH, stir at 25°C for 10h, filter out the resin, which is product B;

[0058] 4) Wash the product B until neutral, add 200mL of 5% NaCl solution, stir for 4 hours, filter out the resin, and dry it in an oven at 50°C to obtain a resin-based nano-lanthanum material—a hydrated lanthanum oxide-201 material.

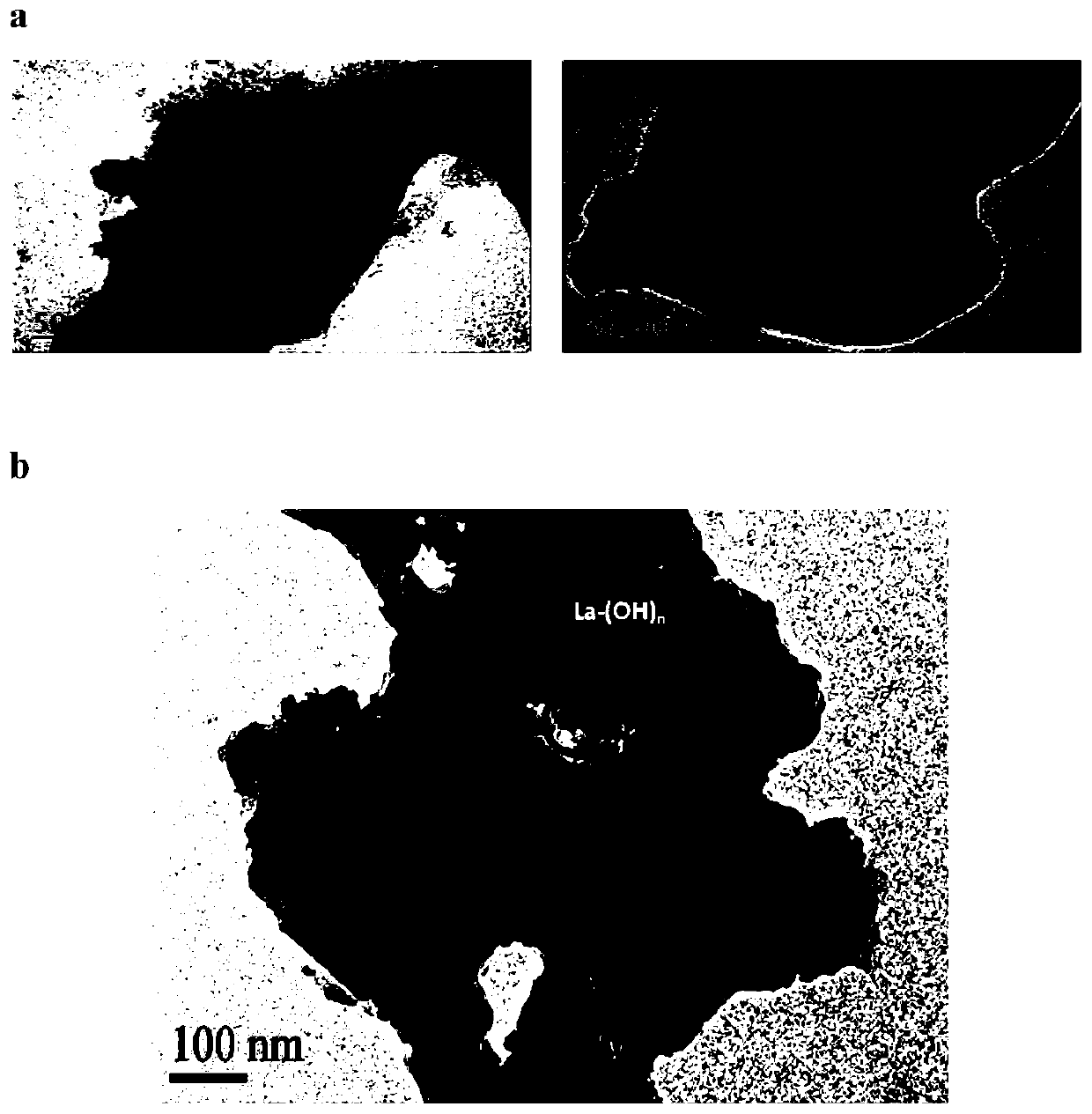

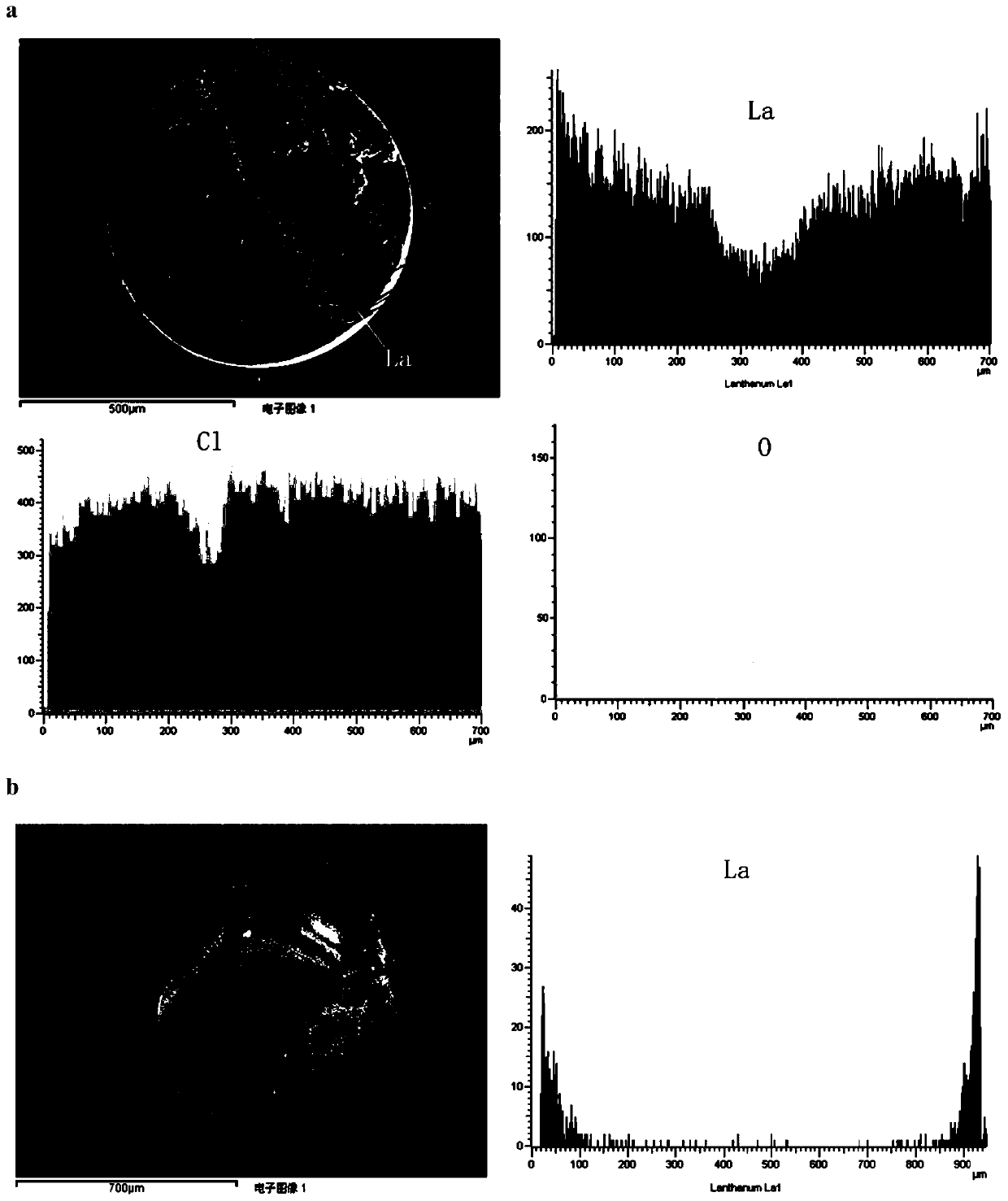

[0059] The material that present embodiment makes is spherical, and diameter 0.3-1.0mm, as figure 2 As shown in a, the nanoparticle size ...

Embodiment 2

[0078] A preparation method of resin-based nanometer hydrated lanthanum carbonate material, the steps are as follows:

[0079] 1) Add concentrated hydrochloric acid with a concentration of 10mol / L into ethanol to prepare 1M HCl ethanol solution, and 10g LaCl 3 Dissolve in 200mL 1M HCl ethanol solution, add 10g D-201 resin, stir at 50°C for 12h;

[0080] 2) filtering the above resin to obtain a resin product A that combines lanthanum in an ion exchange manner;

[0081] 3) Add product A to 200mL 2M NH 4 HCO 3 In the solution, after stirring at 50°C for 8 hours, filter out the resin, which is the product B;

[0082] 4) Wash the product B until neutral, add 5% NaCl solution, stir for 4 hours, filter out the resin, and dry it in an oven at 50°C to obtain the resin-based nano-lanthanum material—a hydrated lanthanum carbonate-201 material.

[0083] The material obtained in this embodiment is spherical, with a diameter of 0.3-1.0mm. After digestion, its lanthanum load is measured ...

Embodiment 3

[0097] A preparation method of a resin-based nanometer hydrated lanthanum oxide material, the steps of which are as follows:

[0098] 1) Add concentrated hydrochloric acid with a concentration of 11-12mol / L into ethanol to prepare a 1M HCl ethanol solution, and add 5gLaCl 3 Dissolve in 200mL 1M HCl ethanol solution, add 5g D-201 resin, stir at 25°C for 12h;

[0099] 2) filtering out the above-mentioned resin to obtain a resin product A in which lanthanum is bound in an ion-exchange manner;

[0100] 3) Add a small amount of product A to 200mL 10% NaOH solution several times, stir at 25°C for 8 hours, filter out the resin, and obtain product B;

[0101] 4) Wash the product B until neutral, add 5% NaCl solution, stir for 4 hours, filter out the resin, and dry it in an oven at 50°C to obtain a resin-based nano-lanthanum material—a hydrated lanthanum oxide-201 material.

[0102] The material obtained in this embodiment is spherical, with a diameter of 0.3-1.0mm. After digestion, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com