Chemical process fault detection method based on adaptive kernel principal component analysis

A nuclear principal component analysis, nuclear principal component technology, applied in electrical testing/monitoring, testing/monitoring control systems, instruments, etc., can solve the problems of scattered or submerged variation characteristics, and high failure detection and false alarm rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

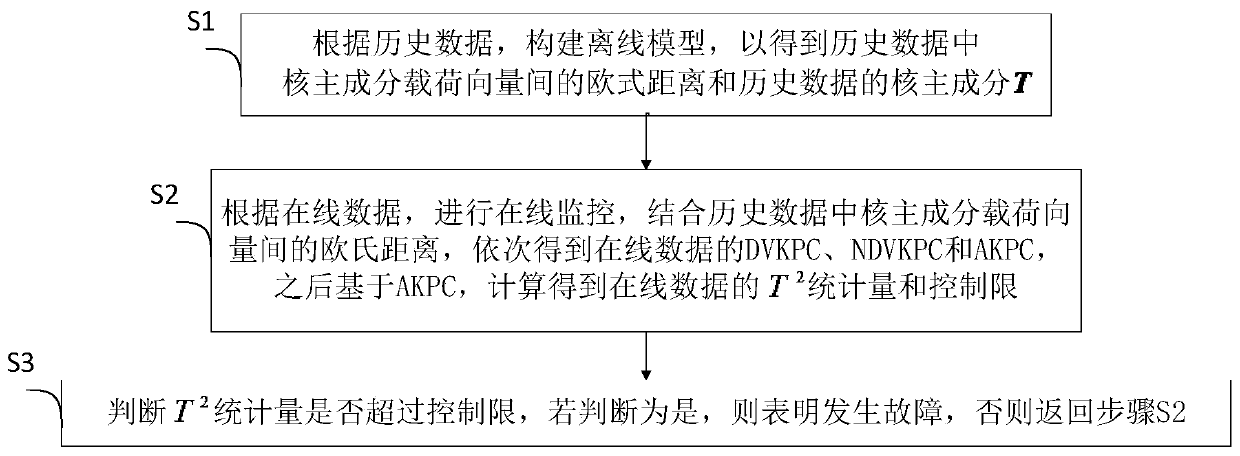

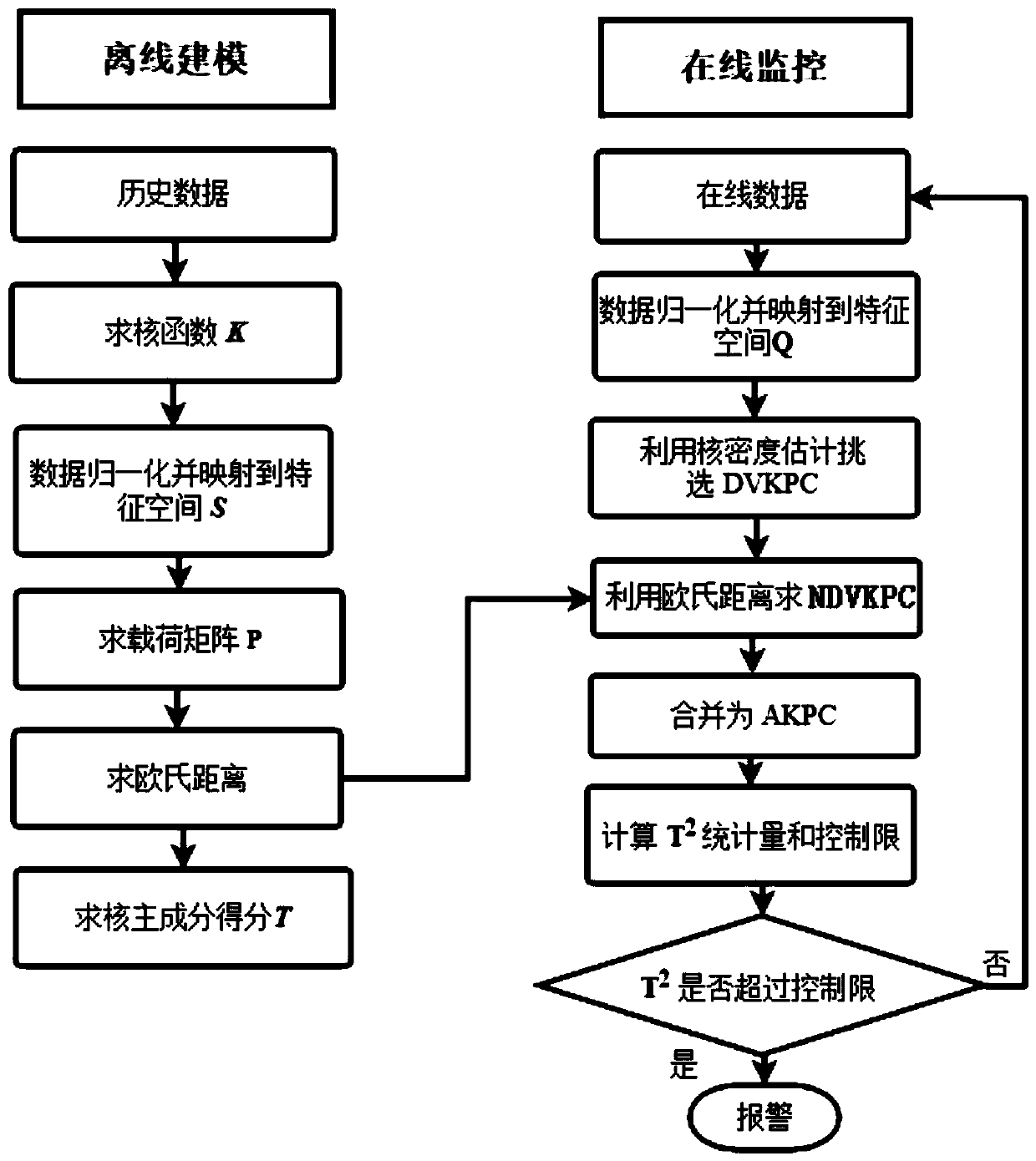

[0071] like figure 1 As shown, a chemical process fault detection method based on adaptive kernel principal component analysis includes the following steps:

[0072] S1. According to the historical data, build an offline model to obtain the Euclidean distance between the kernel principal component load vectors in the historical data and the nuclear principal component T of the historical data;

[0073] S2. According to the online data, carry out online monitoring, combined with the Euclidean distance between the core principal component load vectors in the historical data, sequentially obtain the DVKPC, NDVKPC and AKPC of the online data, and then calculate the T of the online data based on AKPC 2 Statistics and control limits;

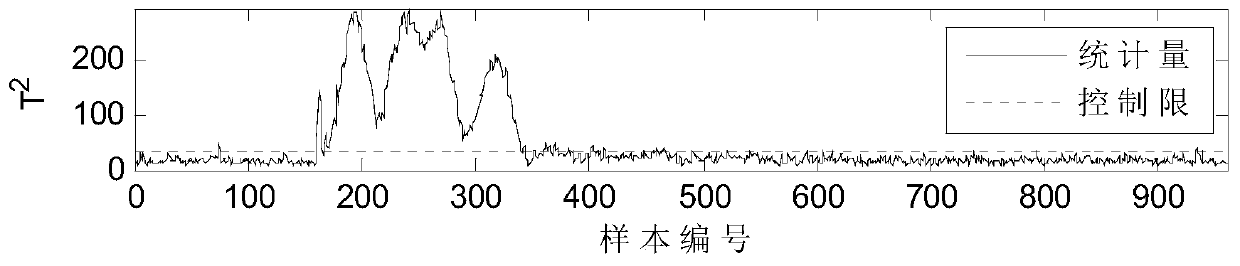

[0074] S3. Judging T 2 Whether the statistical quantity exceeds the control limit, if it is judged to be yes, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com