Water level gauge switch valve for intelligent water conservancy system

An on-off valve, water level gauge technology, applied in electrical switches, electrical components, circuits, etc., can solve problems such as buttons are easily pressed by mistake, abnormal opening or closing, affecting data collection, etc., to achieve easy switching, ensure stable power supply, prevent The effect of accidental power-on or shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

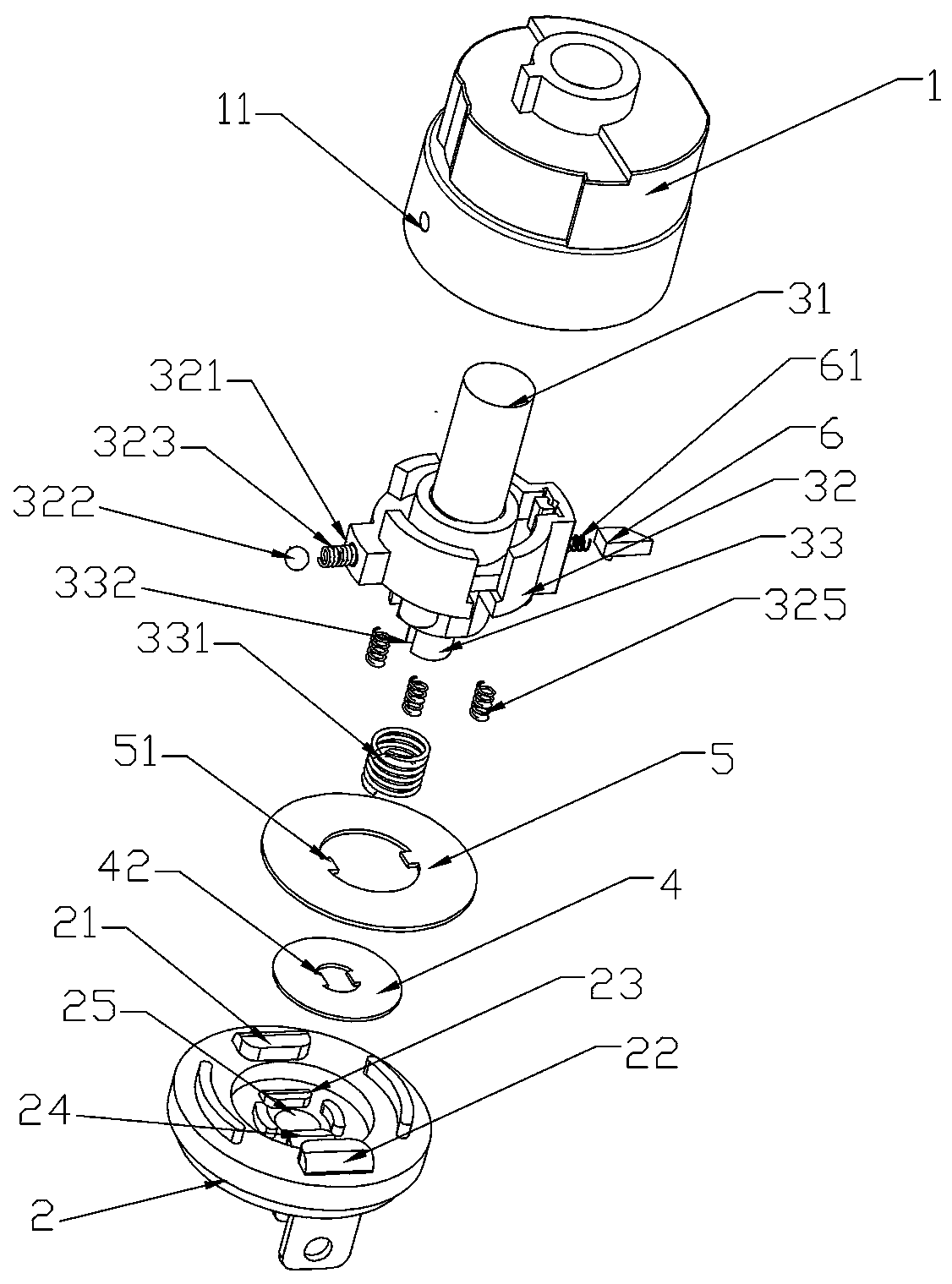

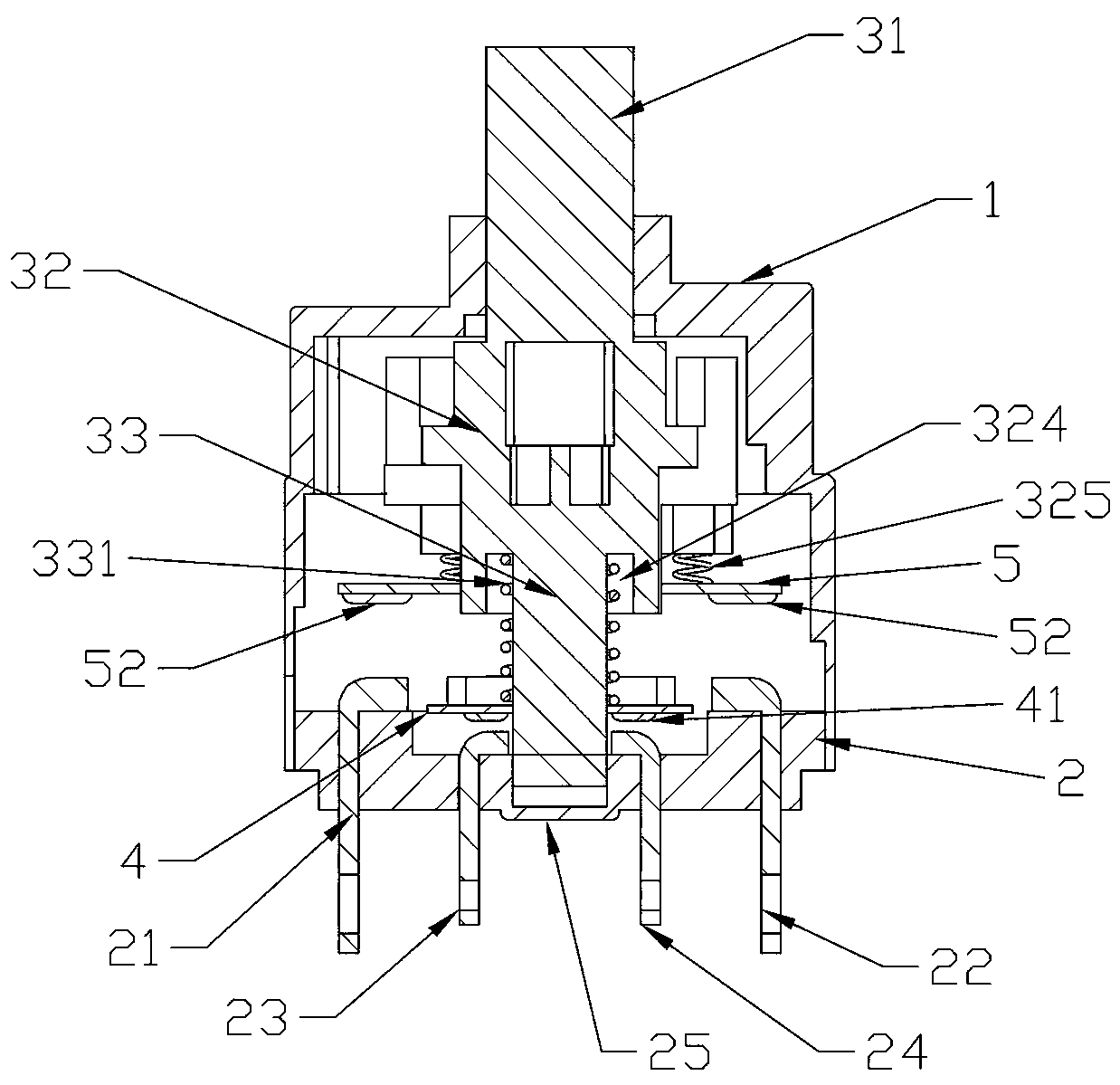

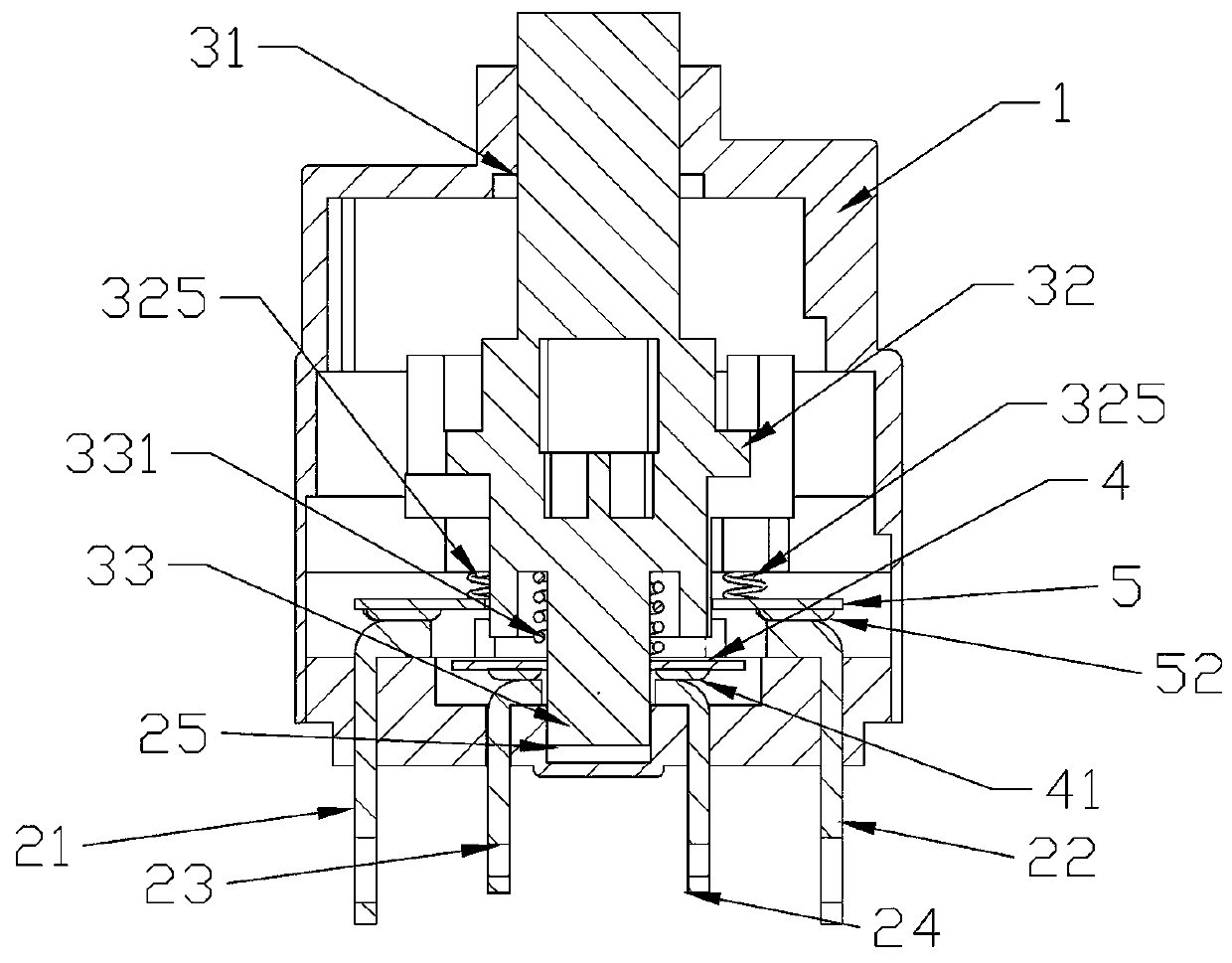

[0022] A water level switch valve for a smart water conservancy system, comprising a casing 1 and a bottom plate 2, the casing 1 is covered on the bottom plate 2, and also includes a valve core, a small contact piece 4 and a large contact piece 5; the valve core Set in the casing; the valve core includes an operating end 31, a limiting end 32 and a contact end 33 from top to bottom; the operating end 31 and the contacting end 33 are arranged at both ends of the limiting end 32; the small contact piece 4 is set on the contact end 33; the middle part of the lower end of the limit end 32 is provided with a circular groove 324; the large contact piece 5 is set outside the circular groove 324; the bottom plate 2 is provided with the first upper contact piece 21, the second The second upper contact piece 22 is in contact with the large contact piece 5, and the first lower contact piece 23 is in contact with the second lower contact piece 24 and the small contact piece 4; in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com