Fishpond aerator based on triboelectricity principle

A technology of friction electricity generation and aeration machine, which is applied in fish farming, application, animal husbandry, etc., can solve the problems of low oxygenation efficiency and poor effect, increase the contact area, improve the efficiency of dissolved oxygen, and inhibit mutual amalgamation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

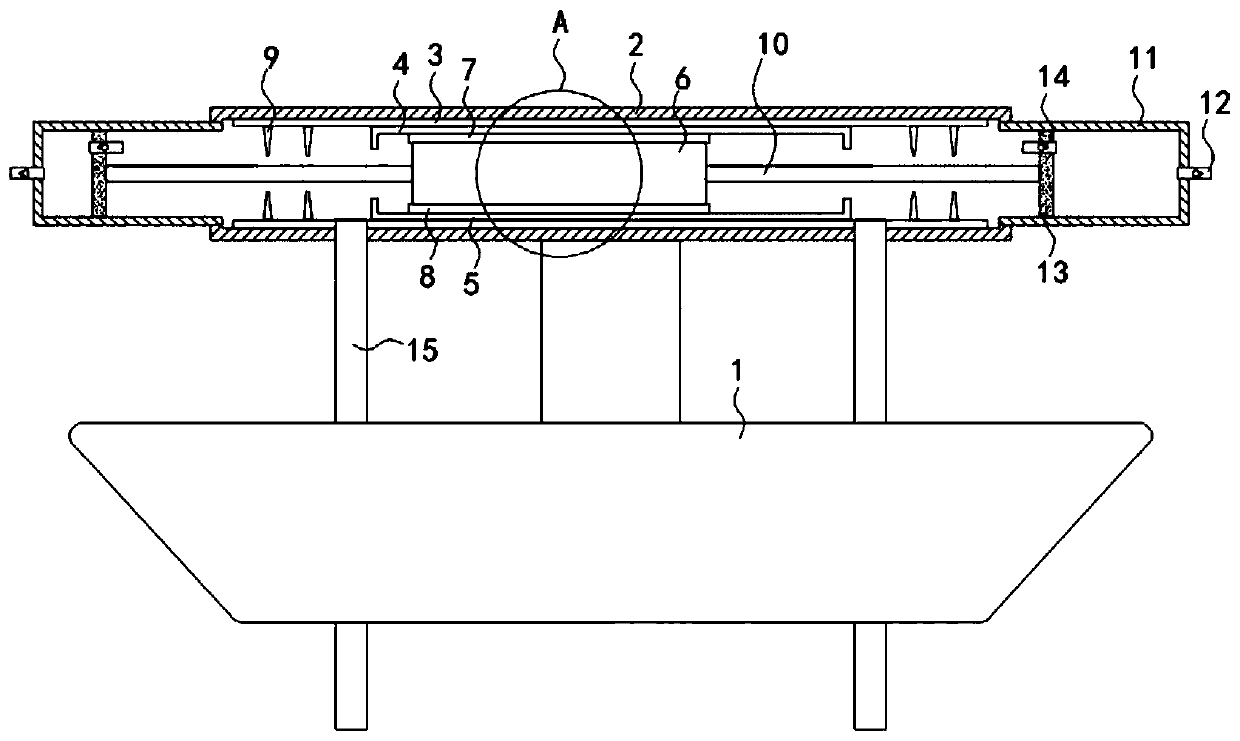

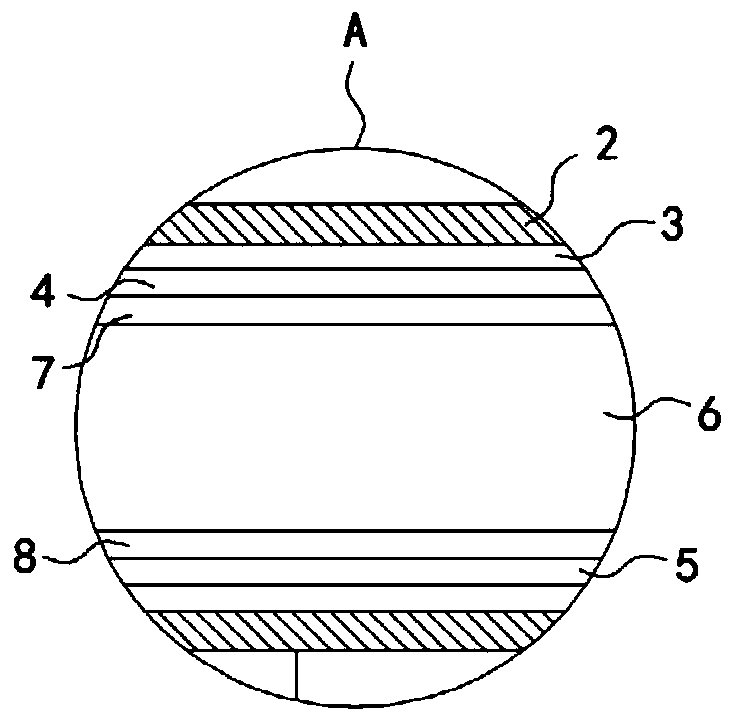

[0017] Such as Figure 1-2 As shown, a fish pond aerator based on the principle of friction electricity generation includes a floating seat 1, the upper end of the floating seat 1 is fixedly connected to a housing 2 through a support column, and the upper top surface and the lower bottom surface of the housing 2 are fixedly connected. There is an induction plate 3, an upper friction plate 4 and a lower friction plate 5 are respectively fixedly connected to the opposite side walls of the two induction plates 3, the lower surface of the upper friction plate 4 is adhered with silk cloth, and the lower friction plate 5 is adhered with fur , the housing 2 is provided with a sliding block 6, the upper friction plate 4, the lower friction plate 5 and the sliding block 6 are all made of insulating materials, the upper end and the lower end of the sliding block 6 are respectively fixedly connected with a glass mesh plate 7 and a rubber mesh plate 8. The glass mesh plate 7 and the rubbe...

Embodiment 2

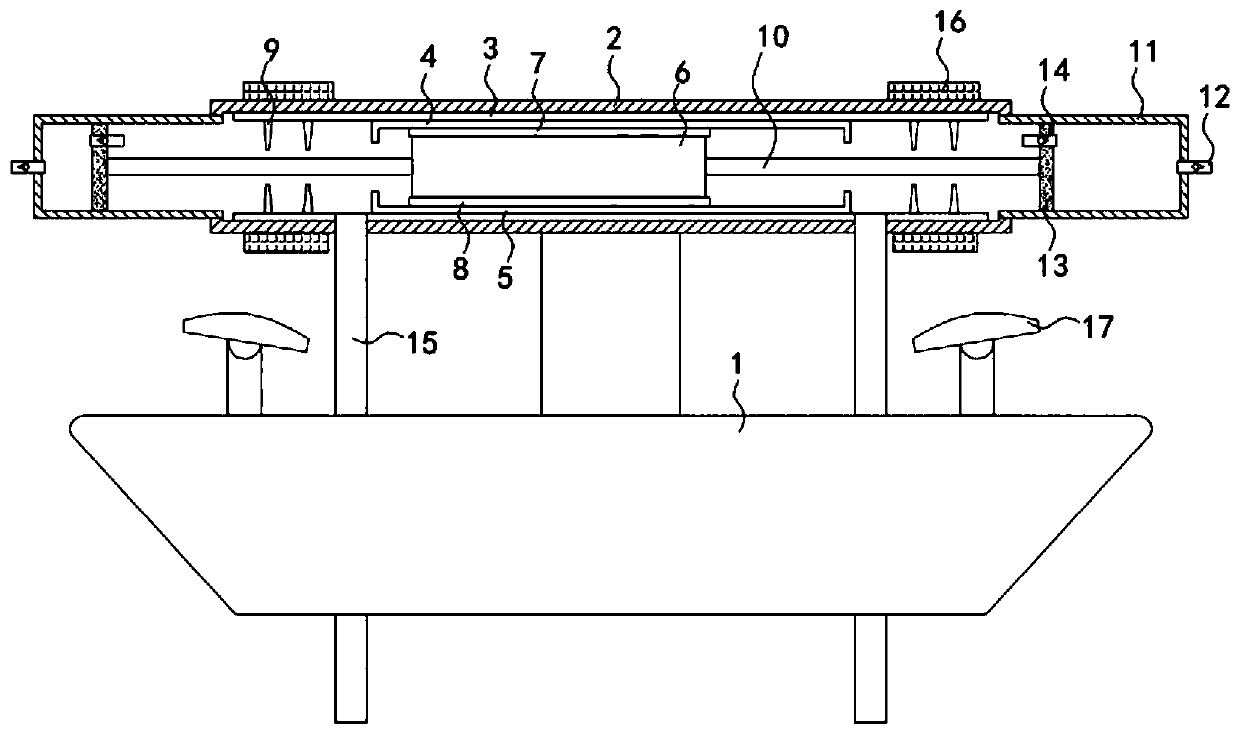

[0022] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the housing 2 is made of a transparent material, and the outer shell 2 is fixedly sleeved with an annular light baffle 16, which is a red translucent light baffle, which acts as To achieve a good anti-glare effect and avoid affecting the normal work of the farmers, the upper surface of the floating seat 1 is fixedly connected with two reflectors 17, and the mirror surface of the reflector 17 is arranged in an upwardly arched arc shape, which can reflect and diffuse light .

[0023] In this embodiment, according to the tip discharge phenomenon, it can be known that when the induced charges on the one-to-one matching discharge needles 9 accumulate to a certain extent, the discharge needles 9 will instantly break through the air and discharge to the outside, resulting in a flash of light, and the light passes through the red half The back of the transparent annular light baffle 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com