Liquid filling and taking device for U-shaped porous glass plate absorption tube

A technology of perforated glass plate and liquid addition device, which is applied in the directions of measuring tube/pipette, burette/pipette support, chemical instrument and method, etc. problems, to avoid low accuracy, reasonable structure design, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

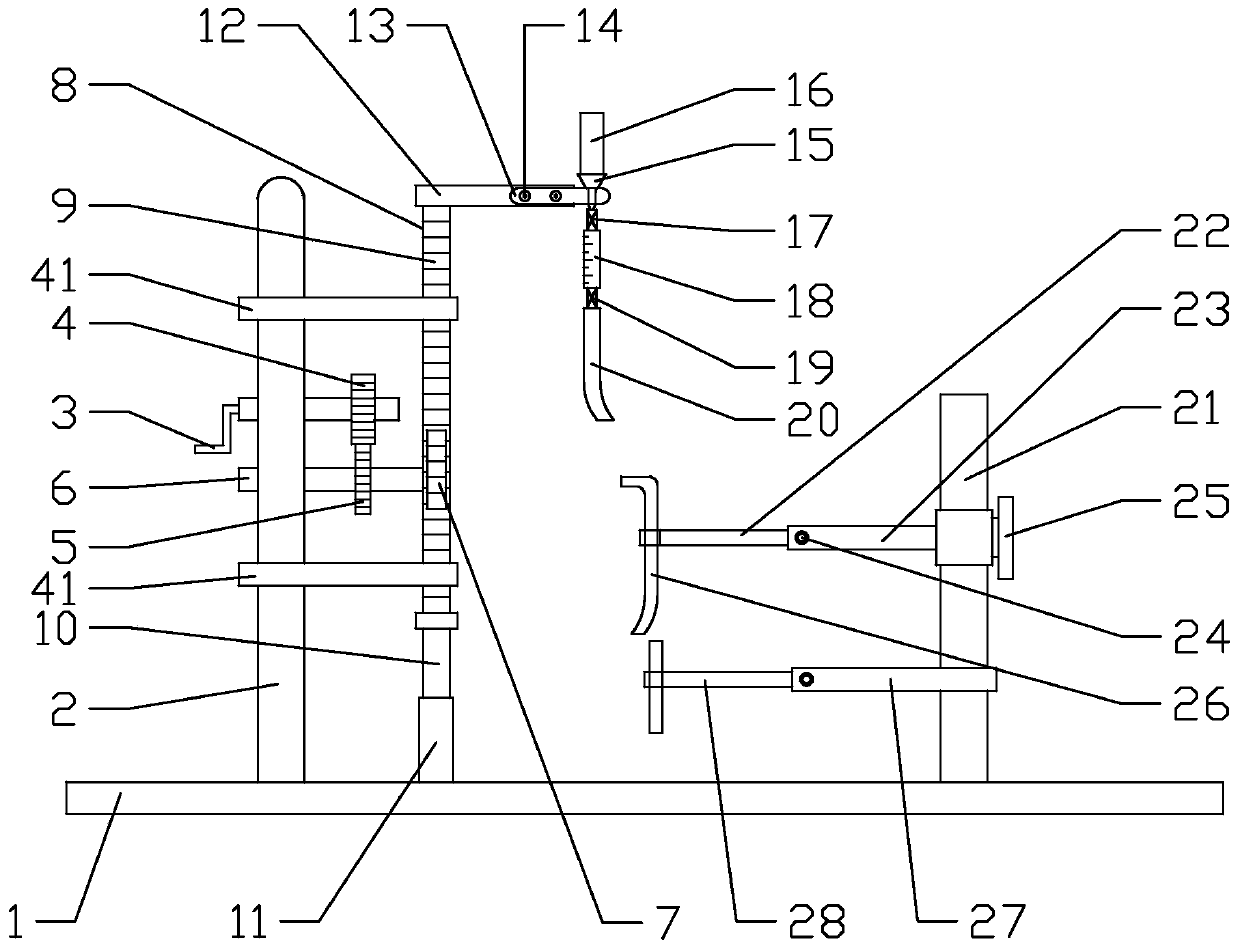

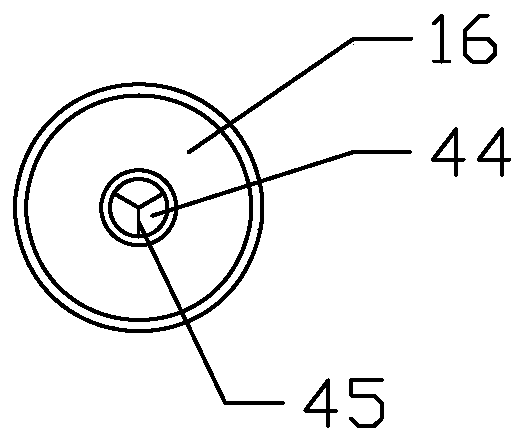

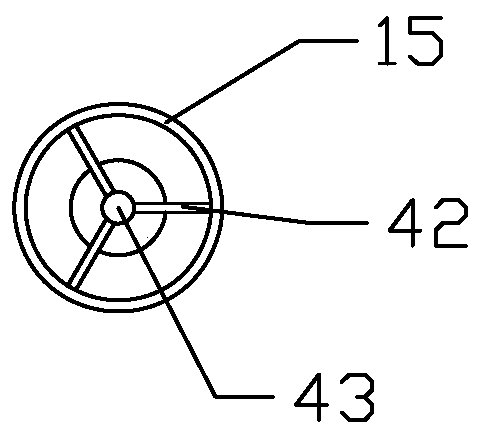

[0027] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0028] Such as Figure 1-4 As shown, a workbench 1 is included, and the workbench 1 is provided with a liquid-feeding regulating fixture, a liquid-feeding device, a liquid-feeding regulating fixture and a liquid-feeding device;

[0029] The affiliated liquid-adding adjustment and fixing device includes a bracket 2 arranged on the workbench 1, on which a rotating shaft is provided through a bearing, the outer end of the bracket 2 is connected with the crank 3, and the inner side of the bracket 2 is provided with a movable gear 4, and the movable gear 4 is connected with a transmission gear 5 through meshing, the transmission gear 5 is fixed on the support 2 through a rod 6, and a driven gear 7 is also arranged on the support rod 6, and the driven gear 7 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com