Gluing machine

A glue applicator and processing box technology, which is applied in the field of glue applicators, can solve problems such as reducing the adhesion of glue, affecting the operation of self-adhesive glue application, and affecting the quality of finished self-adhesive products, so as to improve the quality of finished products and increase the number of coatings. glue effect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

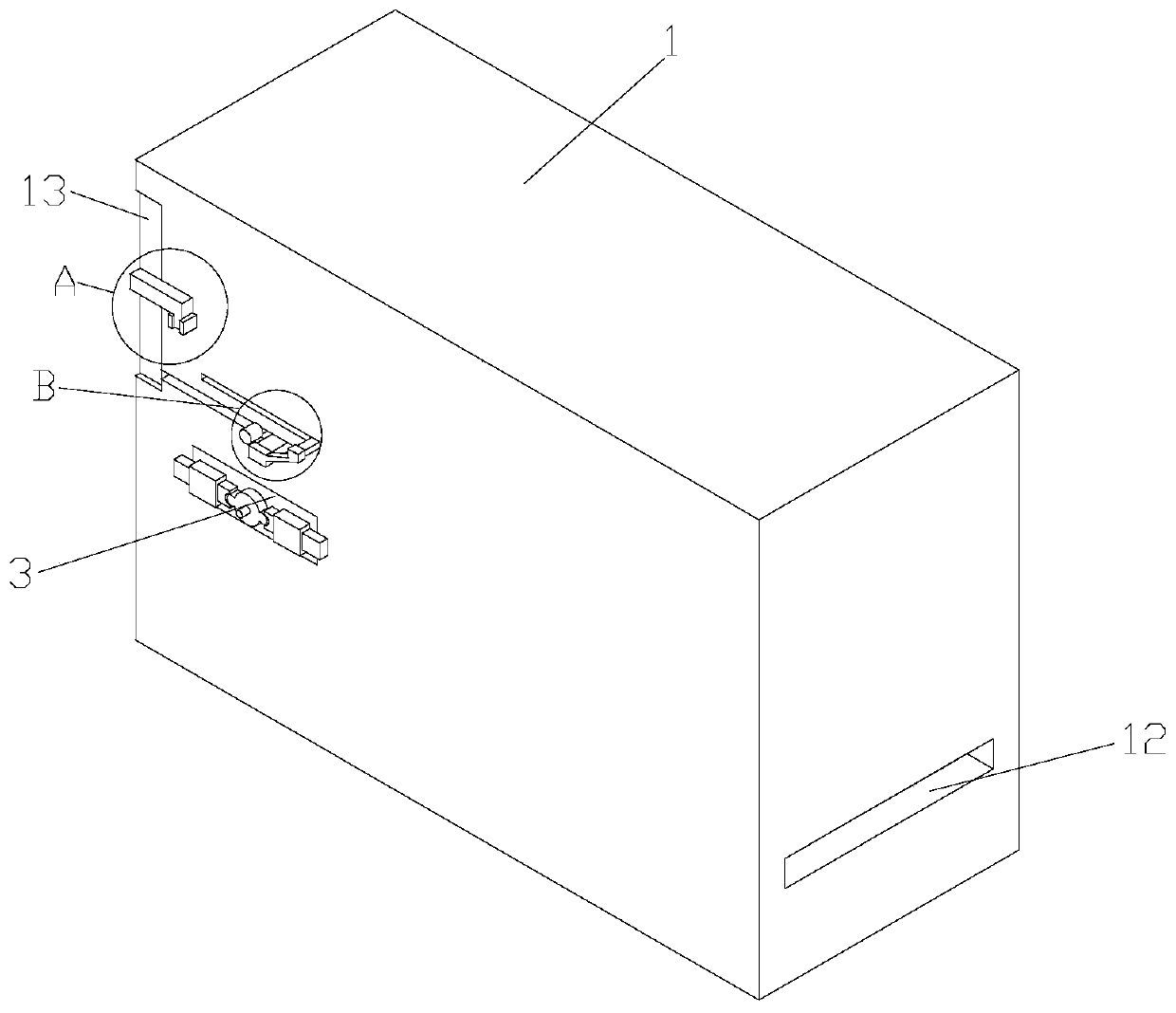

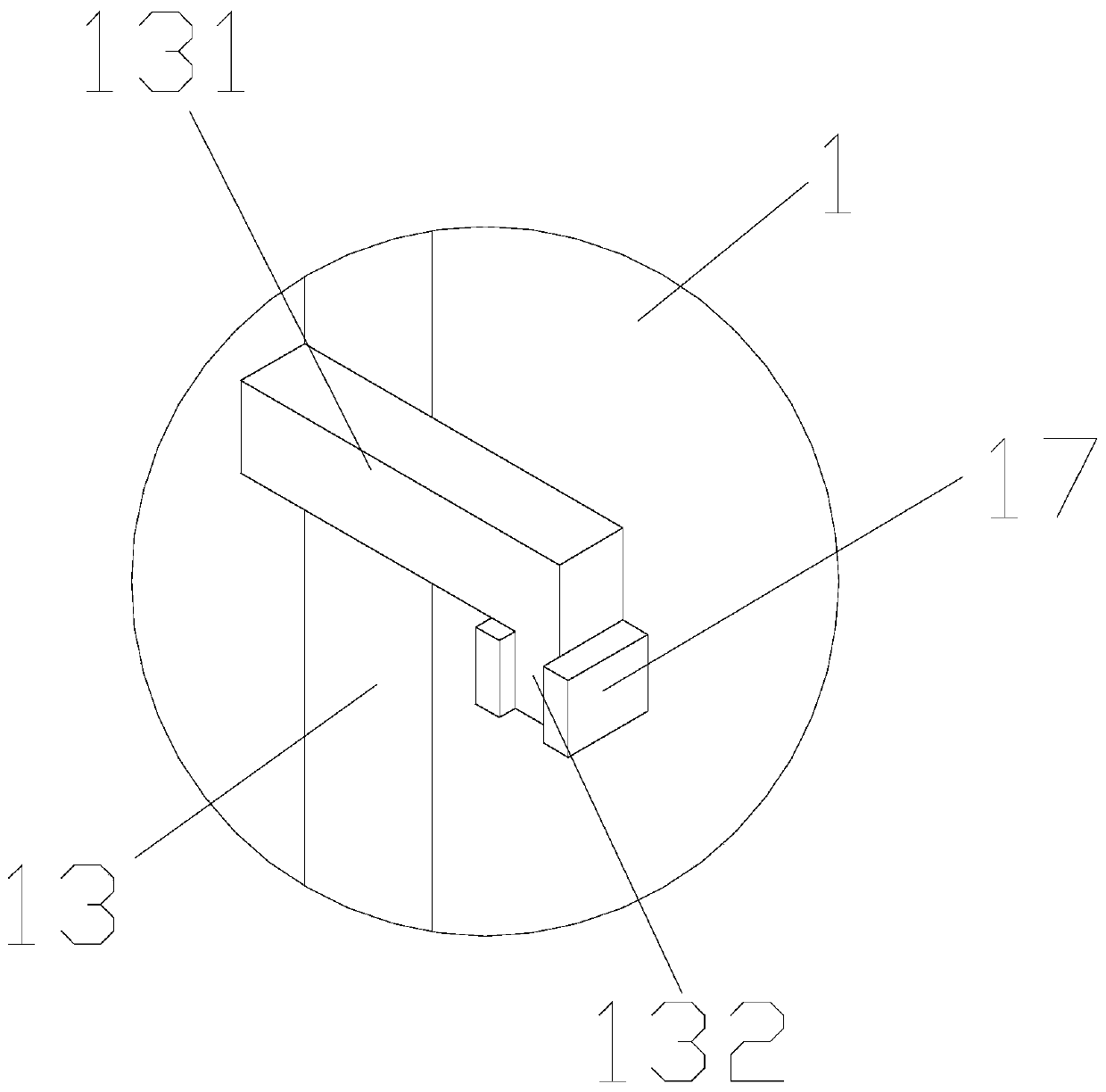

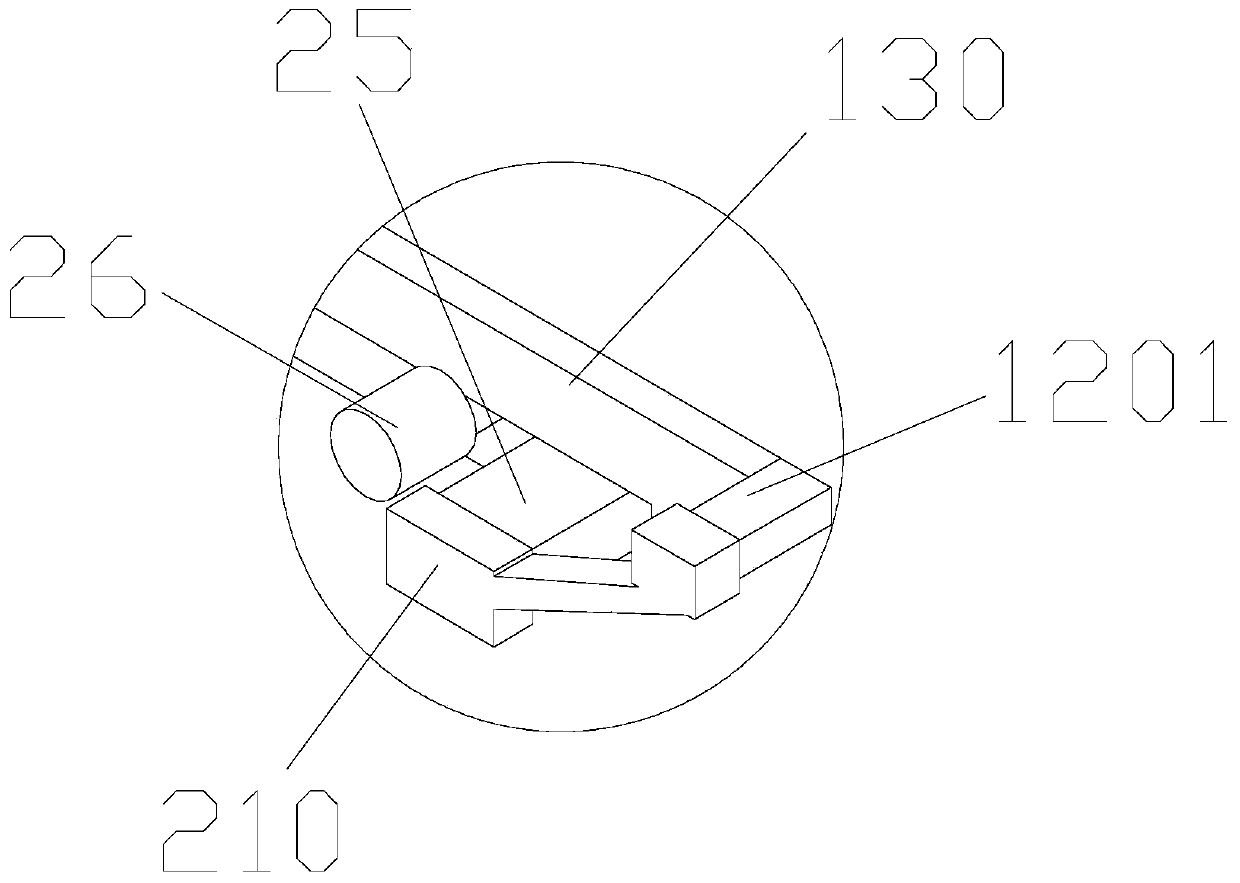

[0030] Such as Figure 1-14 Shown, a kind of gluing machine comprises processing box 1, the first feeding roller 14 that is located in described processing box 1, the second feeding roller 15, the 3rd feeding roller 16 and be located at described 3rd feeding roller 16 The gluing device on one side (not shown in the figure), the structure of the gluing device is the same as the gluing device in the prior art, so it will not be repeated here, the first feeding roller 14, the second feeding roller The roller 15 and the third feeding roller 16 are arranged in a triangular structure, the side wall of the treatment box 1 is provided with a feed inlet 11, and the side wall of the other side is provided with a discharge opening 12, and the side wall of the treatment box 1 is provided with a discharge opening 12. The side wall is also provided with a first chute, the first slide is provided with a first slider, the first slider is provided with a mounting frame 2, and the mounting fram...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap