Steel bar bending system for building construction

A steel bar bending and building construction technology, applied in the field of steel bar bending system, can solve problems such as slippage, irregular shape, inaccurate steel bar bending angle, etc., and achieve the effect of weakening relative sliding, improving stability and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

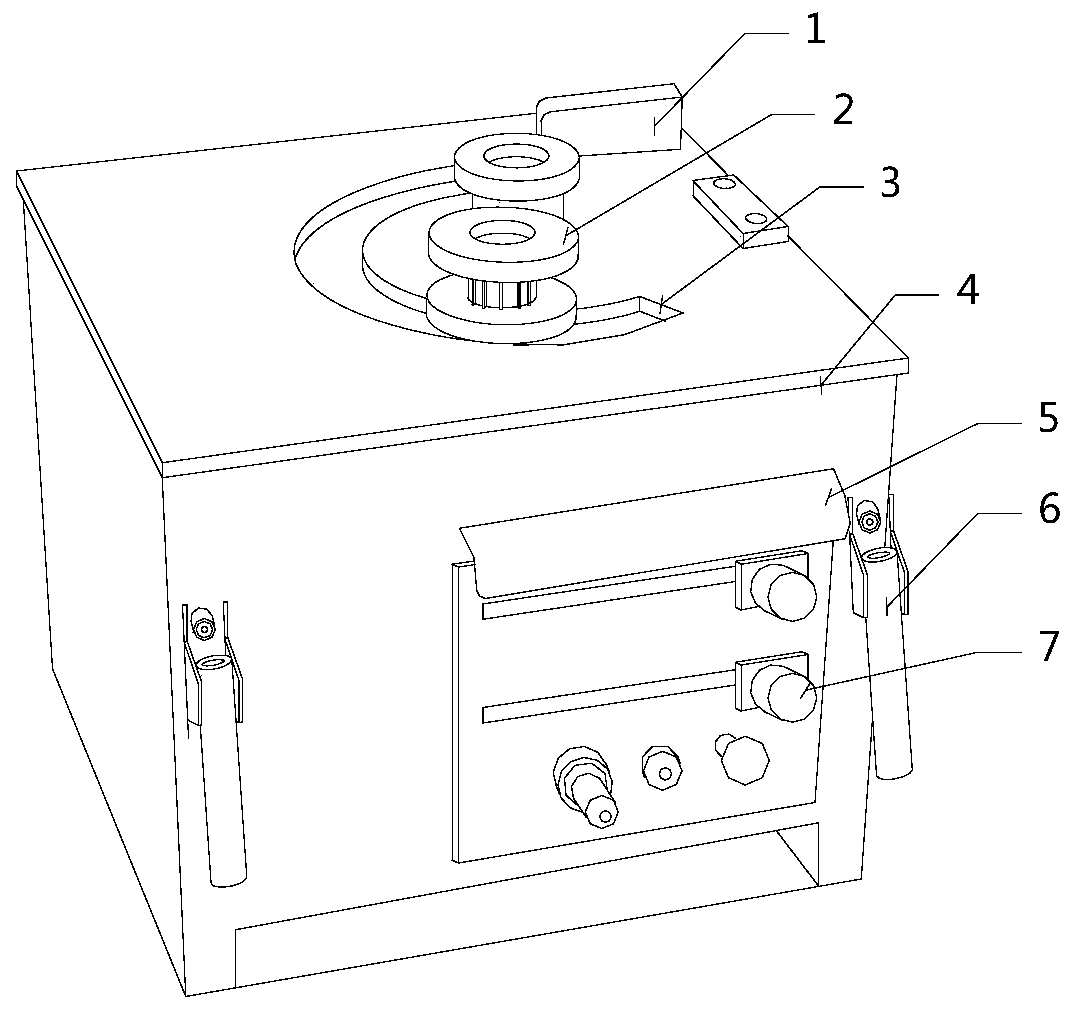

[0024] Please refer to Figure 1-Figure 5 , the present invention provides a steel bar bending system for building construction, the structure of which includes a fixed block 1, a mold 2, a groove 3, a body 4, a shutter 5, a fixed rod 6, and a control panel 7, and the top end of the body 4 faces A groove 3 is arranged in the middle, the groove 3 is an arc structure, a mold 2 is respectively installed at both ends of the arc of the groove 3, and a control panel 7 is installed on the front end of the body 4, and the control panel 7 A shroud 5 is arranged directly above, and the shroud 5 is welded to the body 4, and the control panel 7 is equipped with fixed rods 6 on both horizontal sides.

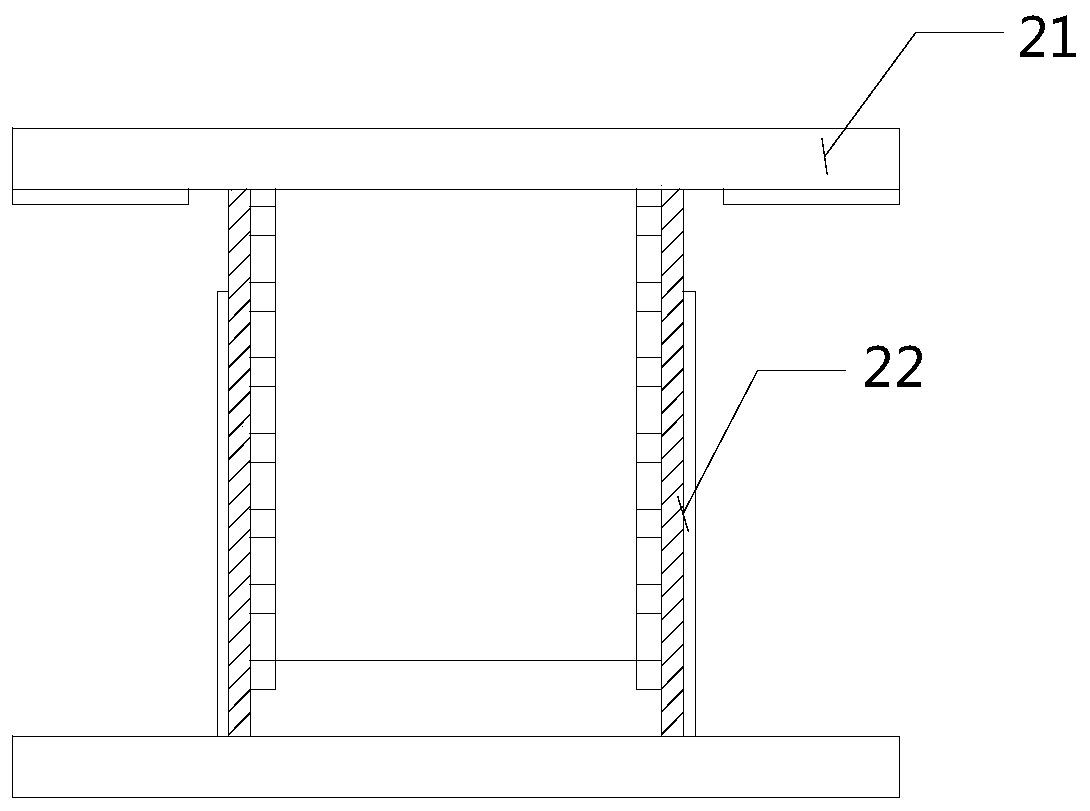

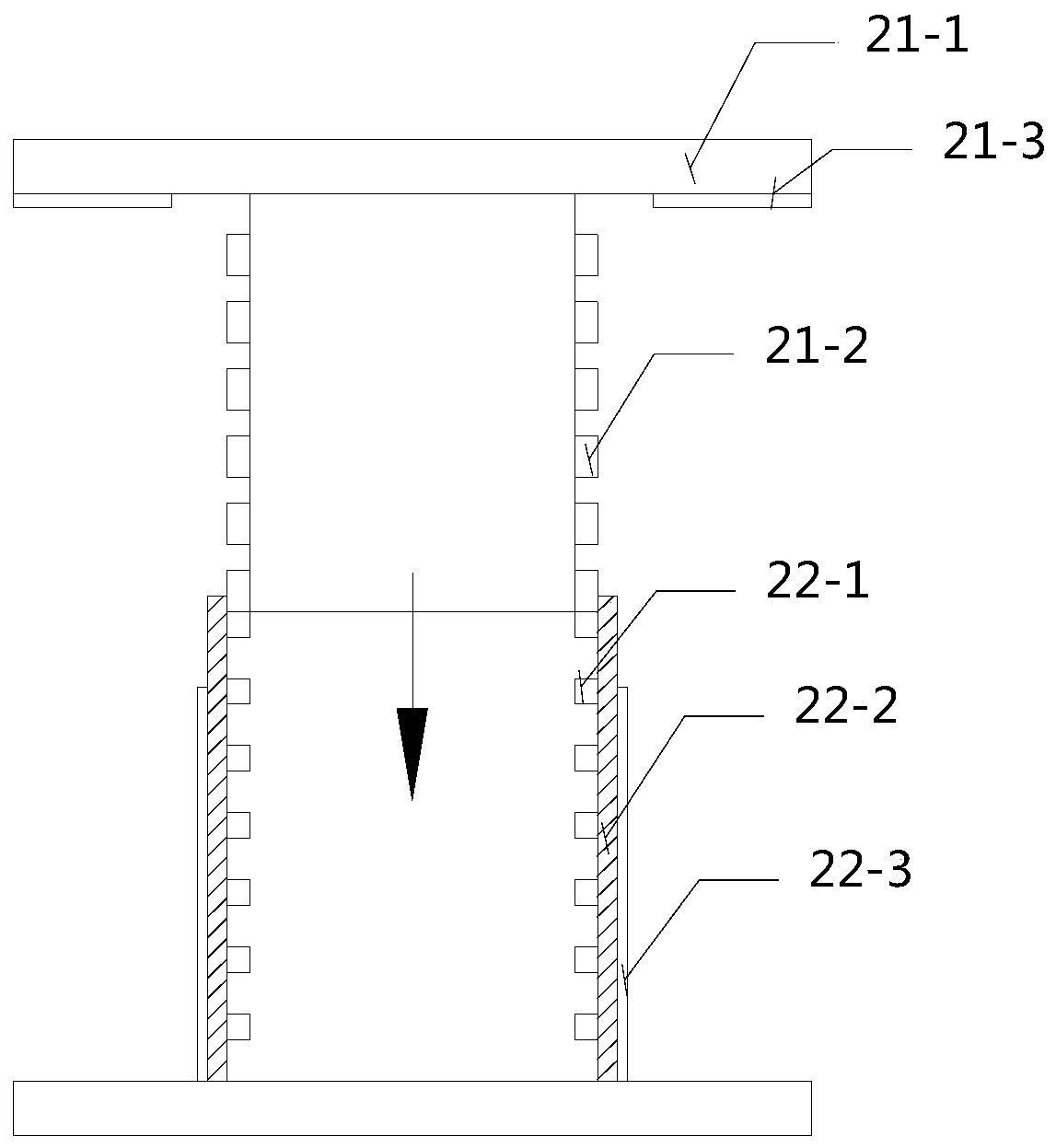

[0025] The mold 2 is provided with an adjustment inner cylinder 21 and a bottom cylinder 22, the bottom cylinder 22 is arranged on the body 4, the adjustment inner cylinder 21 has a "T" shape structure, and the bottom cylinder 22 is an inverted "T" shape Structure, the vertical end of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com