Plate forming flatness control method

A control method and sheet forming technology, applied in ceramic forming machines, auxiliary forming equipment, manufacturing tools, etc., can solve problems such as unfavorable process optimization, inability to completely record flatness parameters, and lack of strict control of human eye inspection quality. The effect of easy disposal and improved detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention are described below by specific specific embodiments. Those who are familiar with the technology can easily understand other advantages and effects of the present invention from the contents disclosed in this specification. Obviously, the described embodiments are part of the present invention. , not all examples. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

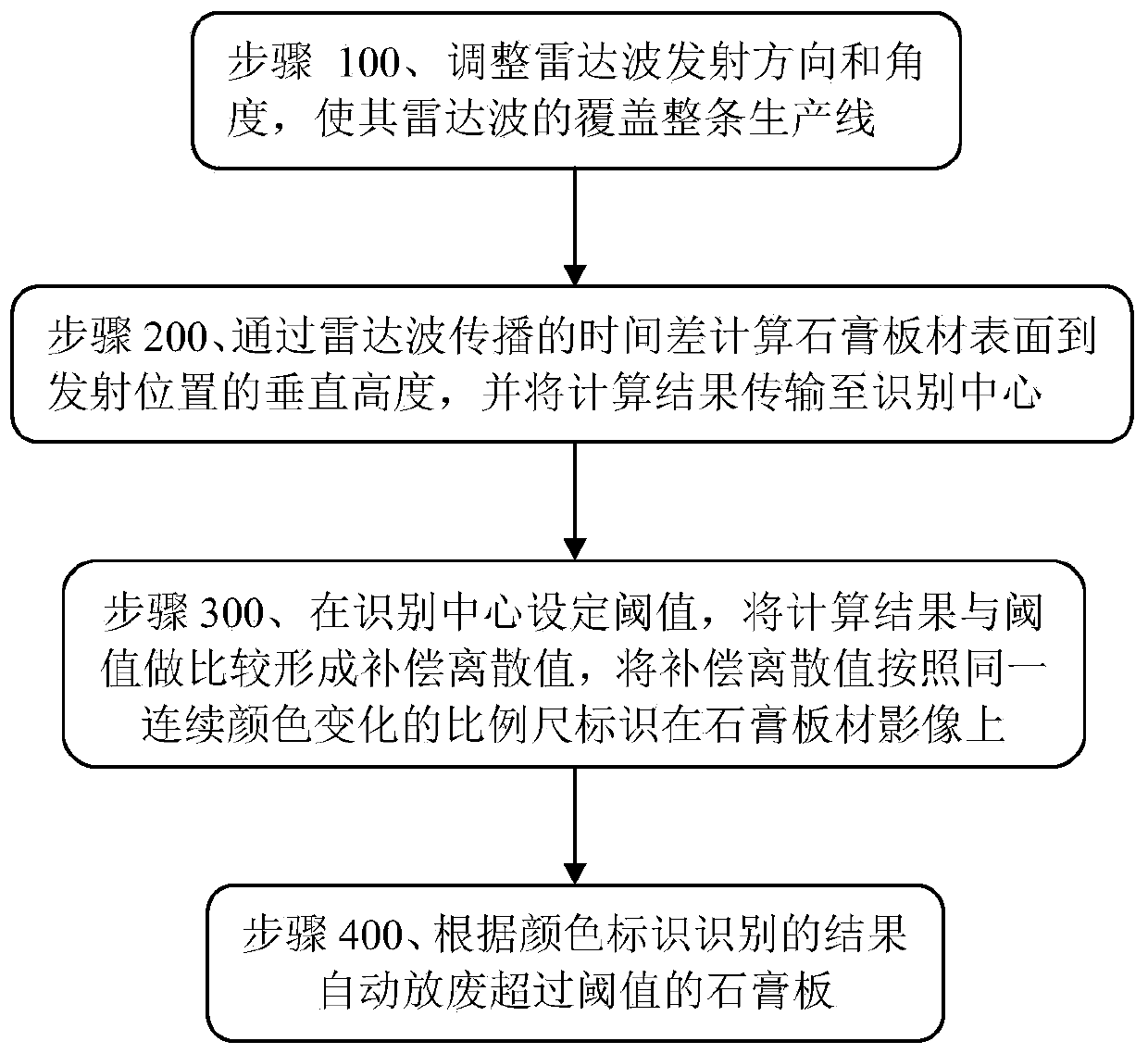

[0040] The invention provides a method for controlling the flatness of sheet metal forming, which mainly includes the following three aspects:

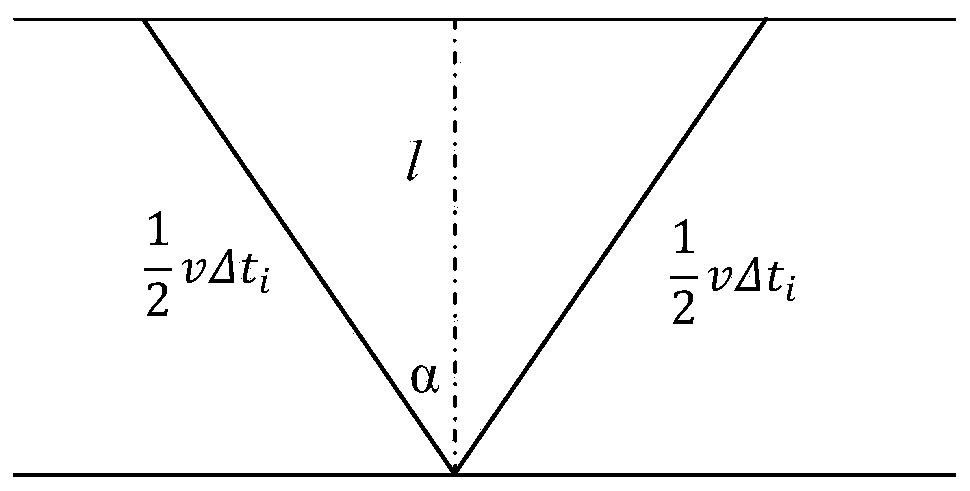

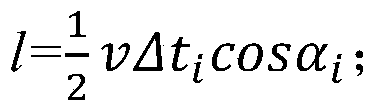

[0041] First, the flatness of the gypsum board is detected by radar waves;

[0042] Second, the test results are fed back to the waste discharge platform, and the unqualified products are determined according to the preset size standard of the gypsum board through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com