A hypersonic cross-flow transition prediction method considering the effect of surface roughness

A surface roughness, hypersonic technology, applied in the testing, measuring devices, instruments, etc. of machine/structural components, can solve the difficulty of realization and promotion, the prediction technology of transverse flow transition cannot be localized, and it is impossible to predict the transverse flow transition, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

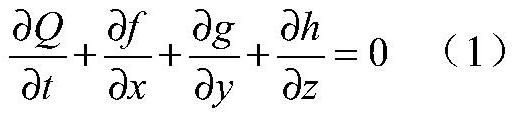

[0056] The invention discloses a hypersonic cross-flow transition prediction method considering the effect of surface roughness. The hypersonic cross-flow transition prediction method at least includes the following steps:

[0057] S1: Let the critical cross-flow Reynolds number and surface roughness satisfy the logarithmic relationship, specifically:

[0058]

[0059] Through step S1, the construction method of the transition criterion based on the hypersonic cross-flow experimental data is given.

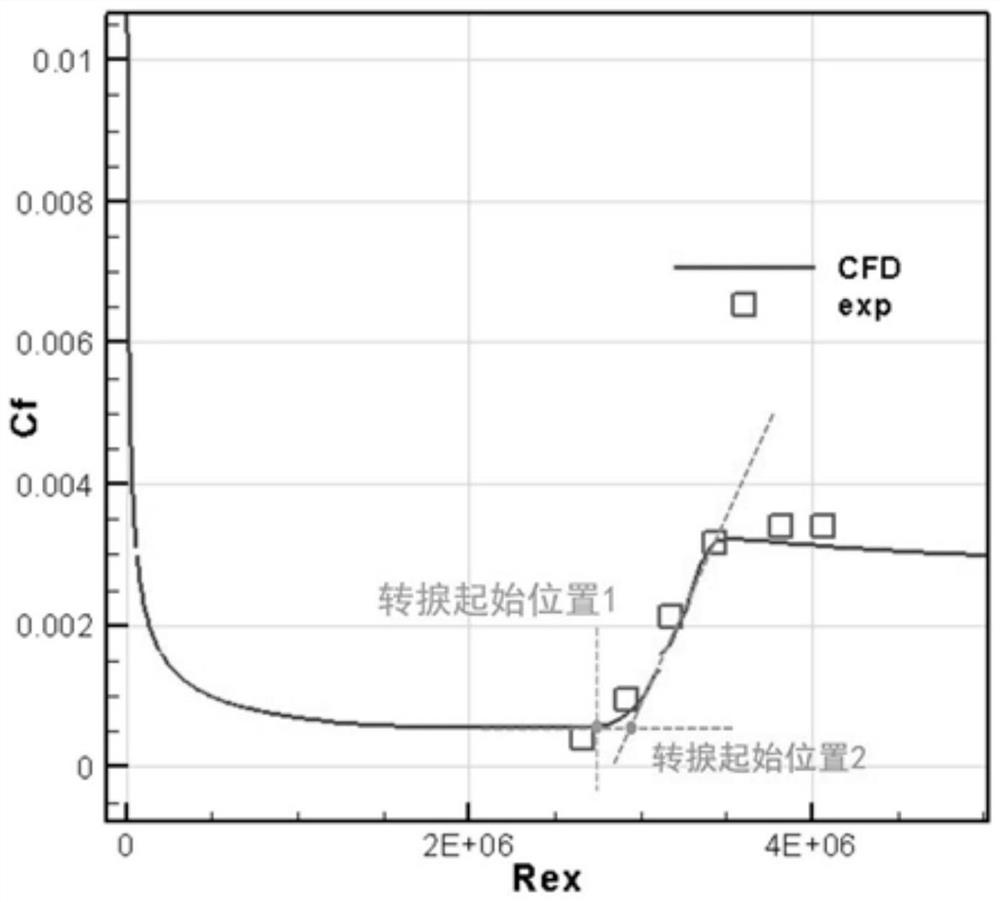

[0060] S2: Based on the existing hypersonic wind tunnel experimental data, the Reynolds number of the transition critical momentum thickness under hypersonic conditions with different roughness is obtained through the CFD laminar flow solution, and the least square method is used to solve the relationship coefficient, and the criterion relationship is obtained:

[0061]

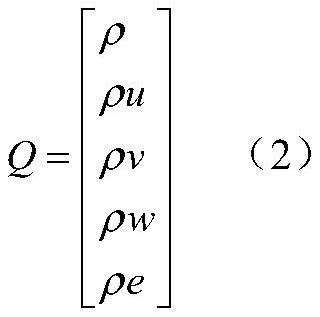

[0062] where Re SCF is the steady cross-flow Reynolds number, h is the surface roughness, θt is the mom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com