Device for jointly removing SO3 and dust in inlet smoke of SCR denitration device

A combined removal and flue gas technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve problems such as easy blockage of absorption liquid supply pipe, exit of SCR denitrification device, reduction of catalyst chemical activity, etc., to achieve equipment and operation Low maintenance cost, small equipment changes, rich mineral resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

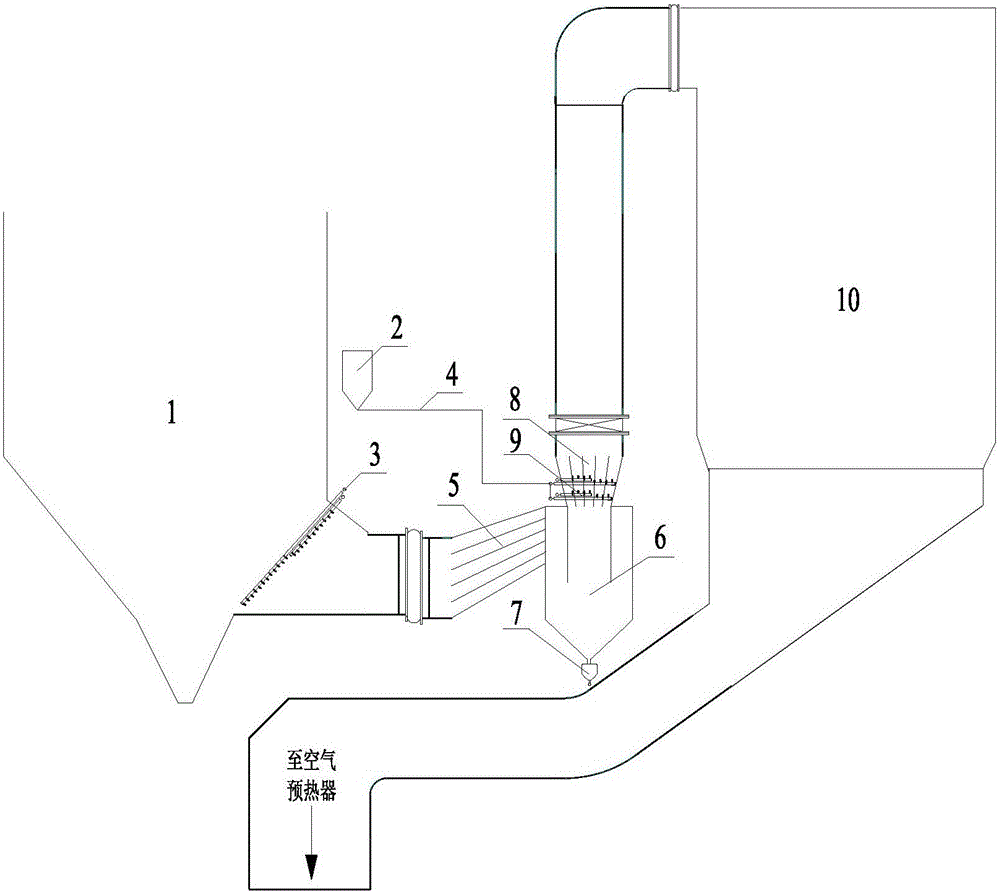

[0022] Such as figure 1 As shown, in this embodiment, the joint removal of SO in the flue gas at the inlet of the SCR denitrification device 3 The device for removing dust and dust includes economizer and its ash hopper 1, absorbent storage device 2, absorbent injection system 3, absorbent delivery system 4, cyclone dust collector inlet flue 5, cyclone dust collector 6, warehouse pump and pneumatic conveying system Ash pipeline 7, cyclone outlet flue 8, ammonia injection grid 9, denitrification reactor 10.

[0023] Arrange absorbent injection system 3 at the outlet of flue gas 1 in the ash hopper of the economizer to inject SO 3 The absorbent trona, the anti-wear plate on the windward side of the absorbent injection system also has the fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com